Method for preparing high iron manganese ore composite sinter

A sinter and high-iron technology, which is applied in the preparation of high-iron-manganese ore composite sinter, and the production of self-fluxing or flux-based high-iron-manganese sinter, can solve the problem of single consolidation ore-forming mode, and achieve good strength and metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

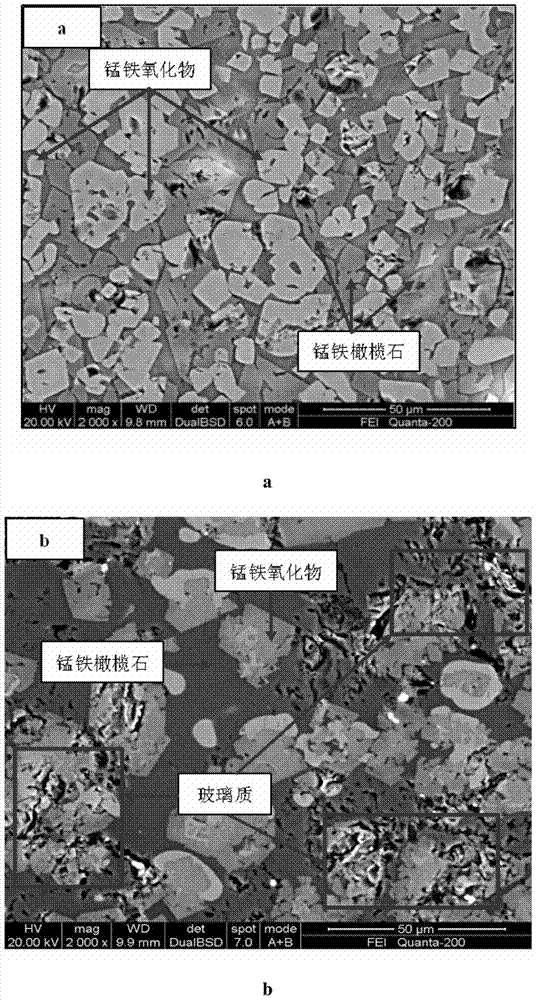

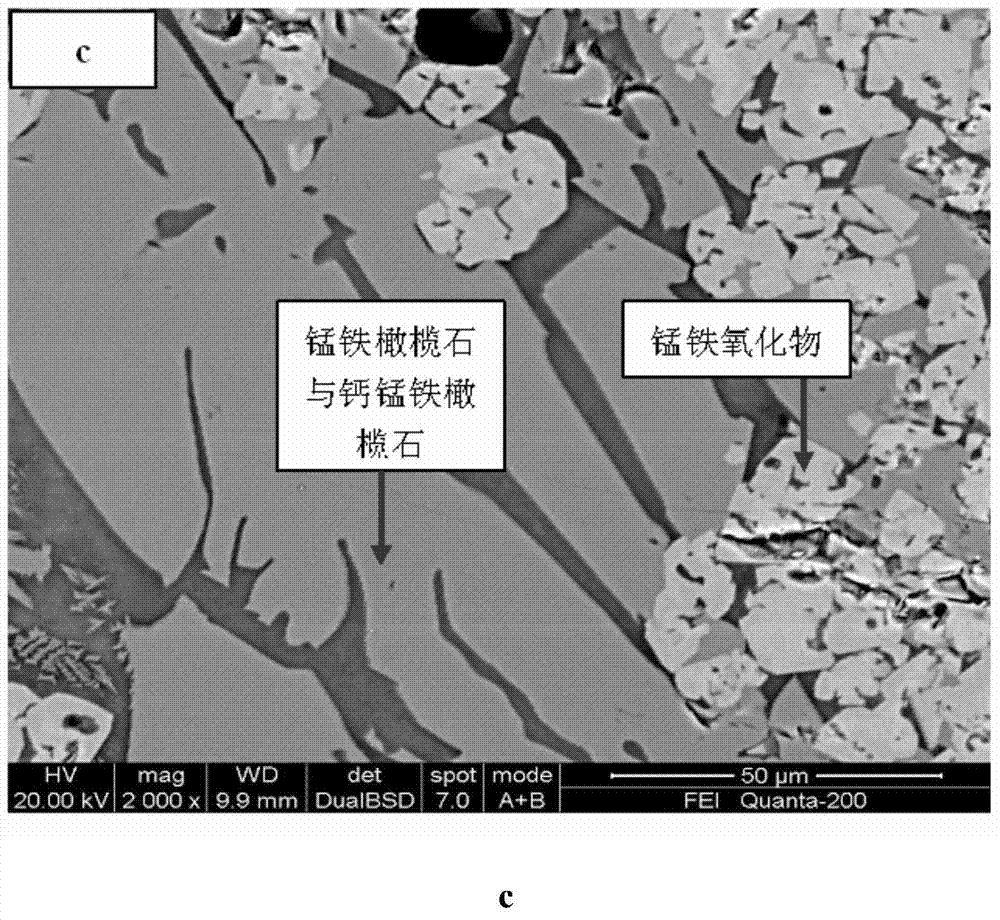

Image

Examples

Embodiment 1

[0031] The ferromanganese ore concentrate (with a particle size of -200mm particle size accounting for 85% by mass and a specific surface area of 1200cm 2 / g), finely ground coke powder (with a particle size of -200mm, the mass percentage is 80%, and the specific surface area is 2000cm 2 / g), binder (bentonite or others) are used as raw materials to prepare pellets, and the particle size of the pellets is 5-8mm, wherein the dry weight of coke powder accounts for 5% of the dry weight of the pellet mixture, and quicklime, white cloud The tribasic alkalinity of the pellets is adjusted to be 0.05; the ferromanganese ore powder, flux, coke powder, and returned ore are used as raw materials, and the pellets are obtained by mixing and granulating, wherein the dry basis weight of the coke powder accounts for 10% of the dry basis mass of the pellets 7.0%, with quicklime, limestone, and dolomite to adjust the ternary alkalinity of the granular material to 1.61, and return 20% to the o...

Embodiment 2

[0033] The high-iron manganese ore concentrate (with a particle size of -200mm particle size accounting for a mass percentage of 88% and a specific surface area of 1320cm 2 / g), finely ground coke powder (with a particle size of -200mm, the mass percentage is 83%, and the specific surface area is 2100cm 2 / g), binder, (bentonite or others) as raw materials to prepare pellets, the pellet particle size is 5 ~ 8mm, wherein the coke powder dry basis weight accounts for 1% of the pellet mixture dry basis mass, with quicklime, Dolomite adjusts the ternary basicity of the pellets to 0.15; the ferromanganese ore powder, flux, and coke powder are returned to the ore as raw materials, and the pellets are obtained by mixing and granulating, wherein the dry weight of the coke powder accounts for 10% of the dry weight of the pellets 10%, with quicklime and dolomite to adjust the ternary alkalinity of the granular material to 1.70, and return 20% to the ore. Then the pellets and pellets ...

Embodiment 3

[0035] The ferromanganese ore concentrate (with a particle size of -200mm particle size accounting for 85% by mass and a specific surface area of 1200cm 2 / g), finely ground coke powder (with a particle size of -200mm, the mass percentage is 80%, and the specific surface area is 2000cm 2 / g), binder (bentonite or others) are used as raw materials to prepare pellets, and the particle size of the pellets is 5-8mm, wherein the dry weight of coke powder accounts for 3.5% of the dry weight of the pellet mixture, and quicklime, white cloud The tribasic alkalinity of the pellets is adjusted to be 0.06; the ferromanganese ore powder, flux, and coke powder are returned to the ore as raw materials, and the pellets are obtained by mixing and granulating, wherein the dry weight of the coke powder accounts for 7.5% of the dry weight of the pellets. %, with quicklime, limestone, and dolomite to adjust the ternary alkalinity of the granular material to 1.73, and return 20% to the ore. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com