A cavitation-resistant laser high-entropy alloying powder on stainless steel surface and its preparation process

A high-entropy alloy, stainless steel technology, applied in metal material coating process, heating inorganic powder coating, coating and other directions, can solve the problem of difficult to obtain component coating, coating forming quality and surface continuity is difficult to meet the requirements of use, etc. problem, to achieve excellent cavitation resistance and reduce brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

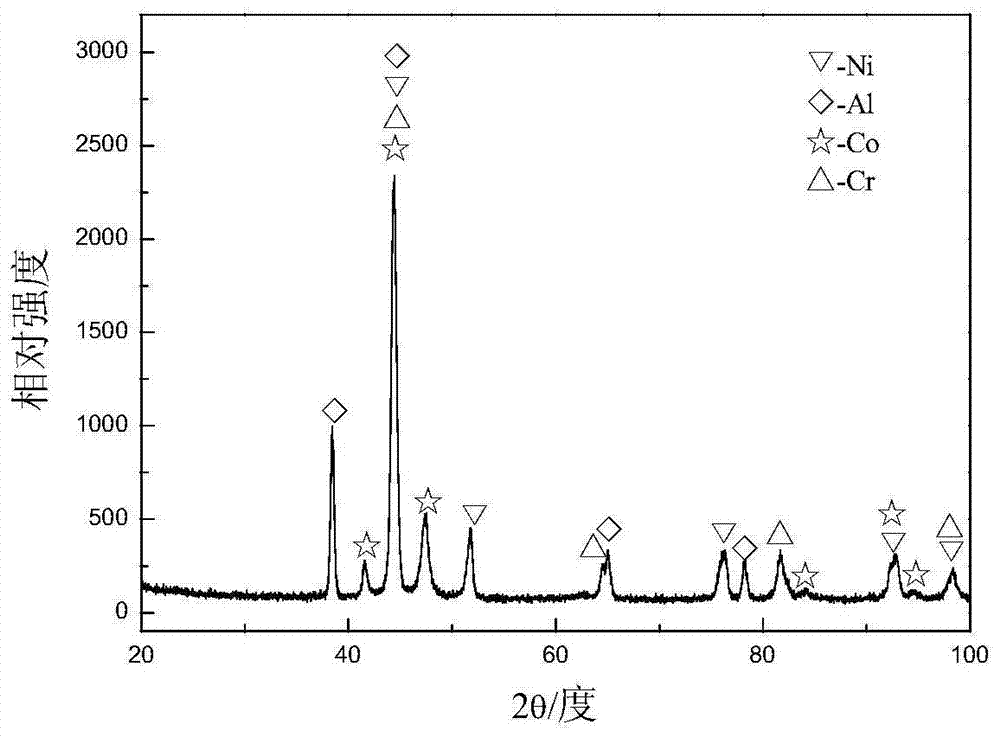

[0053] Preparation of CoCrAlNi / 304 stainless steel laser high entropy alloying coating.

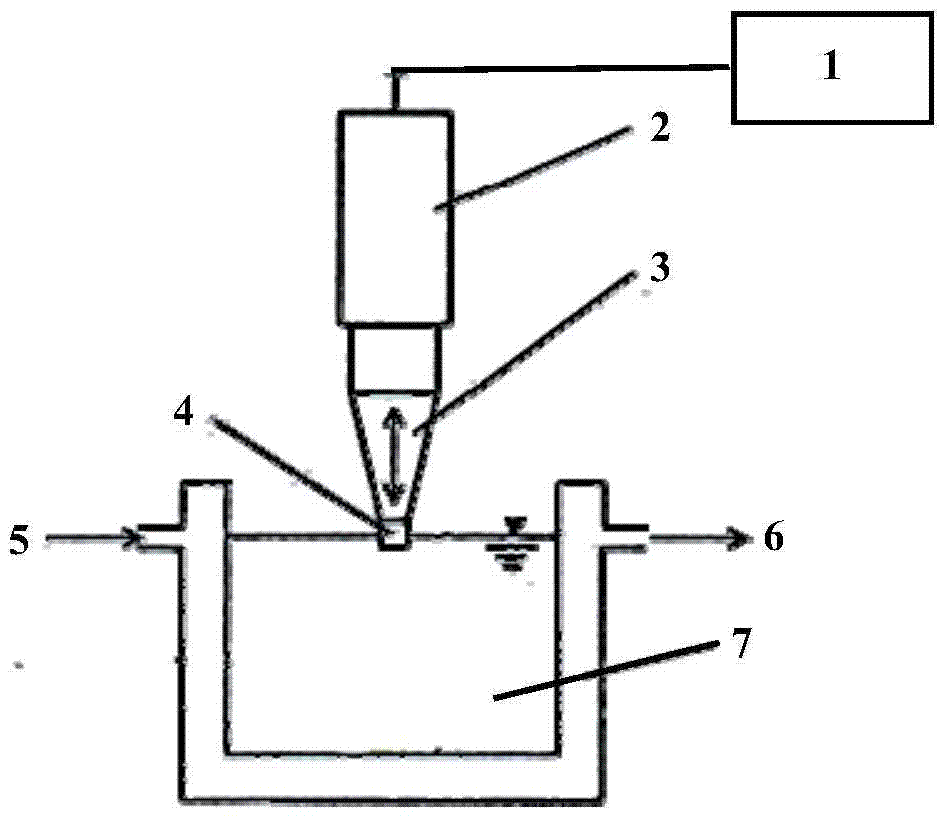

[0054] Co, Cr, Al, Ni alloy powders are prepared at a molar ratio of 1:1:1:1. The powders prepared from pure metal powders are ground and dried and placed on the surface of 304 stainless steel substrates. The thickness of the alloy powders is 0.5~ 0.8mm. Using CO 2 The laser performs single-pass and multi-pass laser irradiation. The specific process parameters are: output power 2kW, spot diameter 3mm, scanning speed 3-7mm / s, large-area laser beam scanning overlap rate of 50%, laser alloy The Ar gas flow rate of the protective gas during the melting process is 15L / min, and the thickness of the obtained laser alloying layer is 0.4-0.8mm.

Embodiment 2

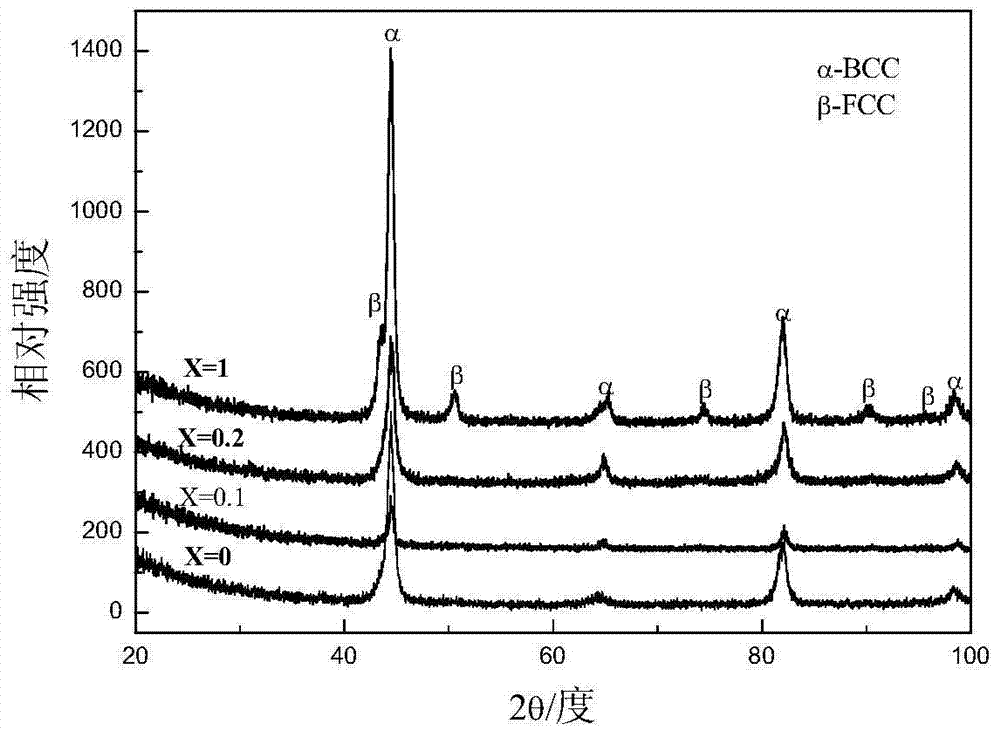

[0056] CoCrAlNiB 0.1 / 304 stainless steel laser high entropy alloying coating preparation.

[0057] Co, Cr, Al, Ni, B alloy powders are prepared at a molar ratio of 1:1:1:1:0.1. The powders prepared from high-purity element powders are ground and dried and then placed on the surface of 304 stainless steel substrates. Alloy powder thickness 0.5 ~ 0.8mm. Using CO 2 The laser performs single-pass and multi-pass laser irradiation. The specific process parameters are: output power 2kW, spot diameter 3mm, scanning speed 3-7mm / s, large-area laser beam scanning overlap rate of 50%, laser alloy The Ar gas flow rate of the protective gas during the melting process is 15L / min, and the thickness of the obtained laser alloying layer is 0.4-0.8mm.

Embodiment 3

[0059] CoCrAlNiB 0.2 / 304 stainless steel high entropy alloy coating preparation.

[0060] Co, Cr, Al, Ni, B alloy powders were prepared at a molar ratio of 1:1:1:1:0.2, and the powders prepared from high-purity element powders were ground and dried and placed on the surface of 304 stainless steel substrates. Alloy powder thickness 0.5 ~ 0.8mm. Using CO 2 The laser performs single-pass and multi-pass laser irradiation. The specific process parameters are: output power 2kW, spot diameter 3mm, scanning speed 3-7mm / s, large-area laser beam scanning overlap rate of 50%, laser alloy The Ar gas flow rate of the protective gas during the melting process is 15L / min, and the thickness of the obtained laser alloying layer is 0.4-0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com