Powder used for laser high-entropy alloying of copper single-element-based alloys and its preparation process

A technology of laser alloying and high-entropy alloying, applied in metal material coating process, coating and other directions, can solve the problems of difficult coating forming quality and surface continuity, poor formability of modified layer, etc., and achieve simple solid solution phase structure, reducing brittleness, improving hardness and the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

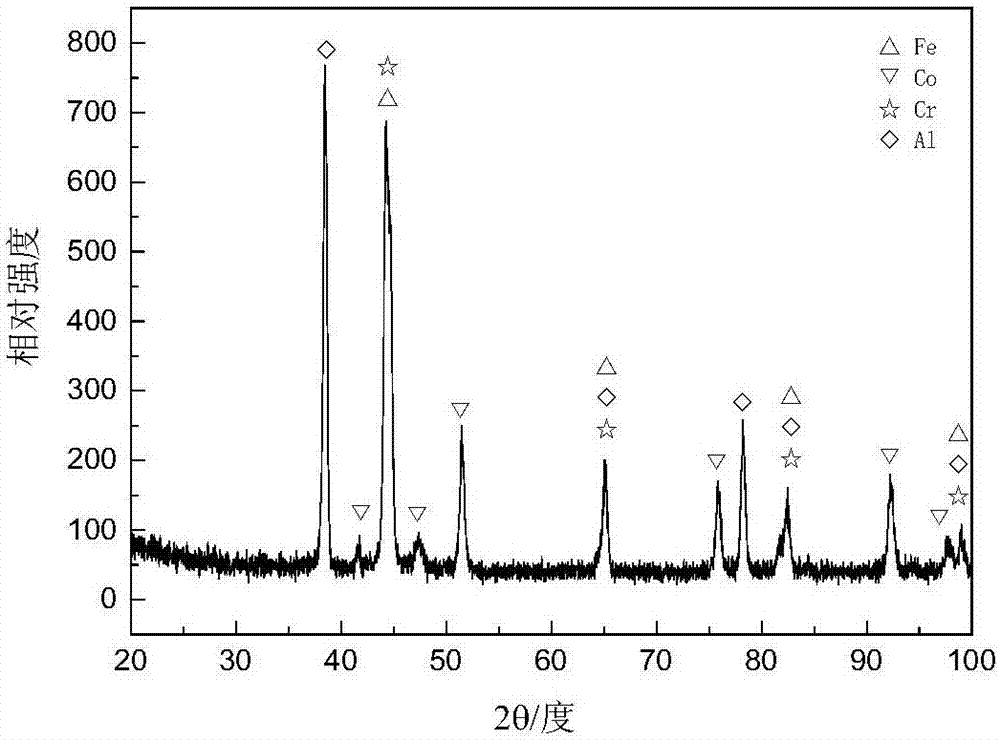

[0041] Preparation of FeCoCrAl quaternary alloy powders.

[0042] The FeCoCrAl quaternary alloy powder is prepared in an equimolar ratio of 1:1:1:1, and the prepared alloy powder needs to be ground and mixed in a star ball mill or a mortar for 2-5 hours. The ball milling or grinding of the mixed powder is carried out at room temperature, the temperature is 23±1°C, and the relative humidity is 40±10%. Then place the uniformly mixed powder in a vacuum drying oven for 2-8 hours for later use, and the alloy powder does not react during the ball milling process.

Embodiment 2

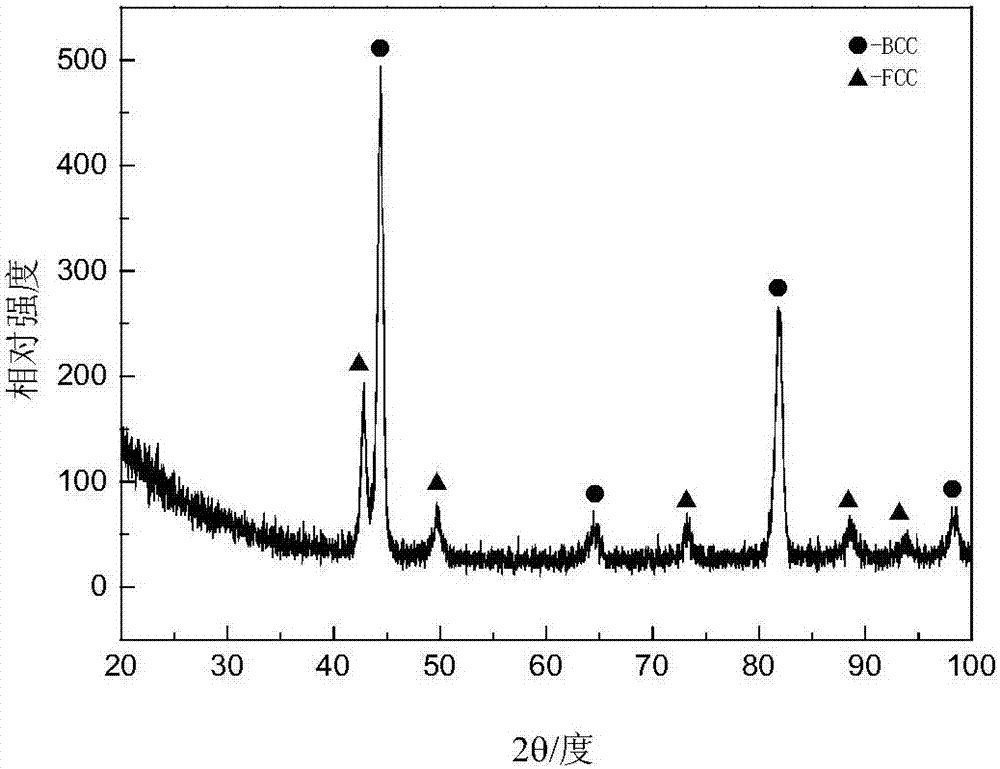

[0044] Preparation of FeCoCrAlCu laser high-entropy alloying layer on the surface of copper substrate.

[0045] FeCoCrAl alloy powder is prepared at an equimolar ratio of 1:1:1:1. The prepared powder is ground and dried and then placed on the surface of the copper substrate. The thickness of the alloy powder is 0.5-0.7mm. Nd:YAG solid-state pulsed laser is used for single-pass and multi-pass laser irradiation alloying treatment. The specific process parameters are: voltage 380V, current 150-170A, spot diameter 1.2mm, scanning speed 4mm / s. During the laser alloying process, the protective gas argon flow rate is 10-20L / min, and the main element copper of the single-element-based alloy substrate melts into the coating to participate in the surface alloying process during laser irradiation, and the thickness of the laser alloyed layer is 0.3- 0.5mm.

Embodiment 3

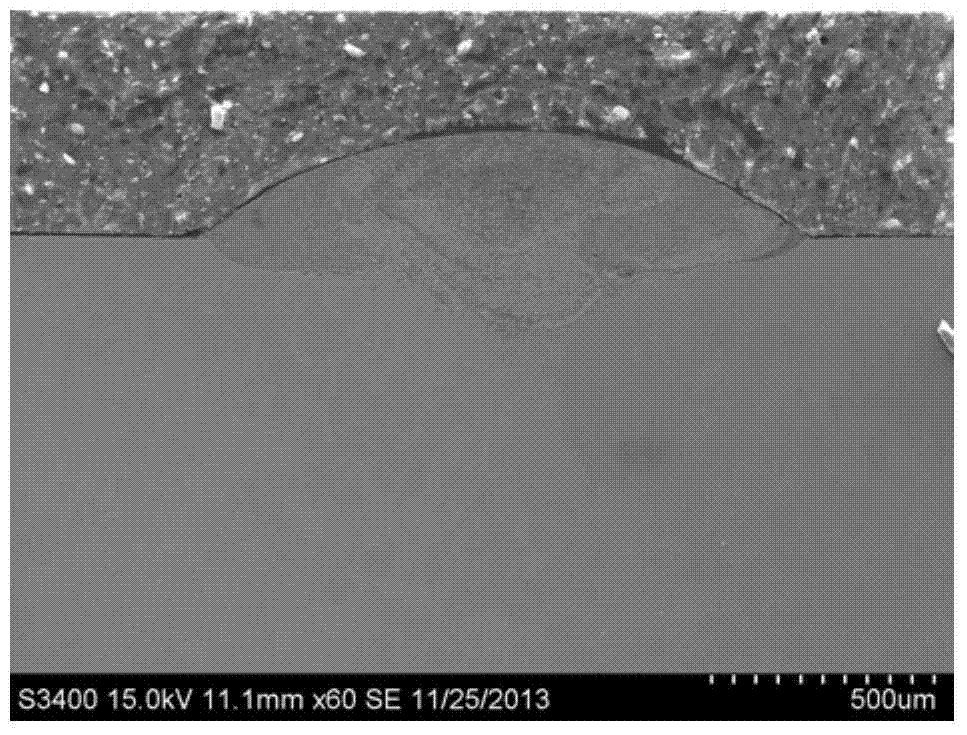

[0047] The FeCoCrAlCu alloyed layer on the surface of the copper substrate was prepared under the condition of low laser irradiation process parameter current (I=130A).

[0048] FeCoCrAl alloy powder is prepared at an equimolar ratio of 1:1:1:1. The prepared powder is ground and dried and then placed on the surface of the copper substrate. The thickness of the alloy powder is 0.5-0.7mm. A Nd:YAG solid-state pulsed laser is used for single-pass laser irradiation. The specific process parameters are: voltage 380V, current 130A, spot diameter 1.2mm, and scanning speed 4mm / s. During the laser alloying process, the protective gas argon flow rate is 10-20L / min. The content of matrix elements in the prepared coating layer is very low, and a large number of cracks appear in the coating layer, making it difficult to form a metallurgical bond.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com