A two-path reaction device

A technology of reaction devices and reactors, which is applied in the direction of measuring devices, feeding devices, chemical methods for reacting liquid and gas media, etc., can solve the problems of not being able to meet the requirements of reaction experiments, single functions, etc., and achieve improved evaluation and analysis efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

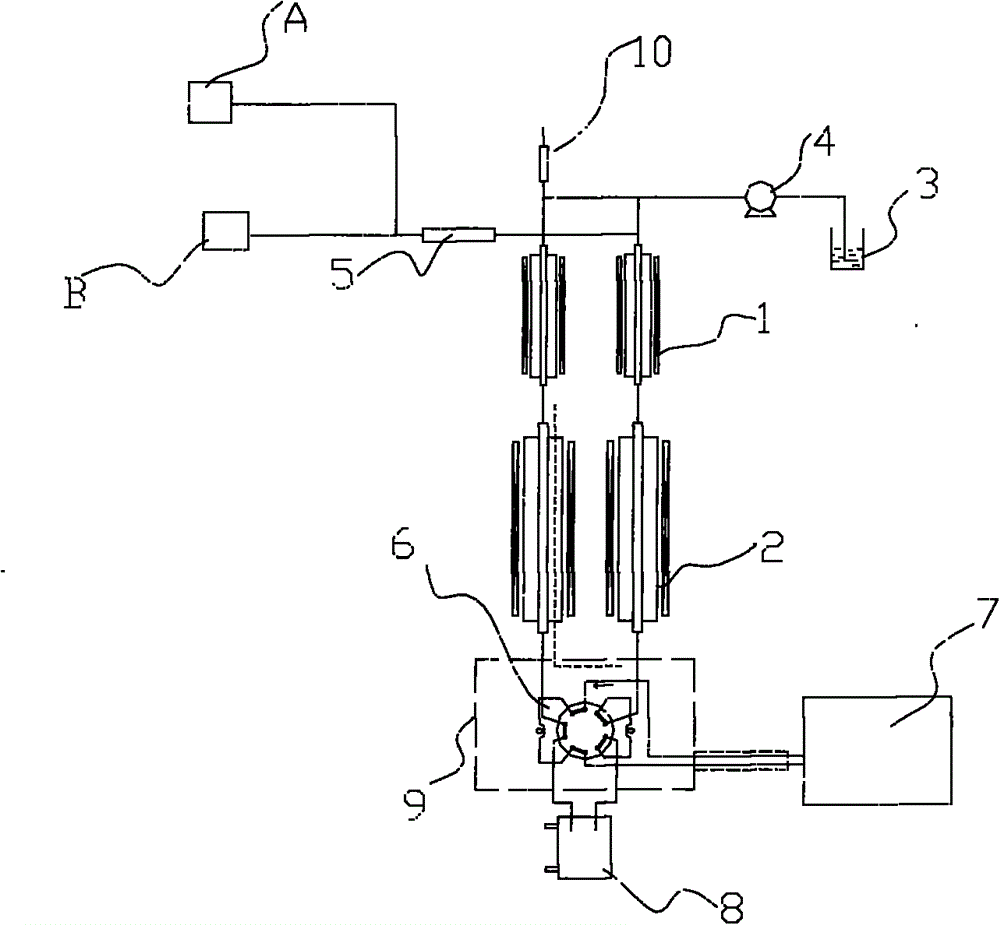

[0012] see figure 1 As shown, the figure shows the structure of a two-way reaction device provided by the embodiment of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0013] see figure 1 , a two-way reaction device, comprising two parallel reactors 2, one end of the reactor 2 is respectively connected to a vaporizer 1, and the other end of the vaporizer 1 is connected to a double gas source A, B is connected to the liquid storage tank 3, and the connecting pipeline between the vaporizer 1 and the gas path mixer 5 and the liquid storage tank 3 is provided with a safety valve 10; the other end of the reactor 2 is connected to the The chromatograph 7 and the condenser 8 are connected, and the ten-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com