Fast wiring terminal

A terminal, fast technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problem of slow connection, troublesome lock, etc., and achieve the effect of improving the efficiency of wiring installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

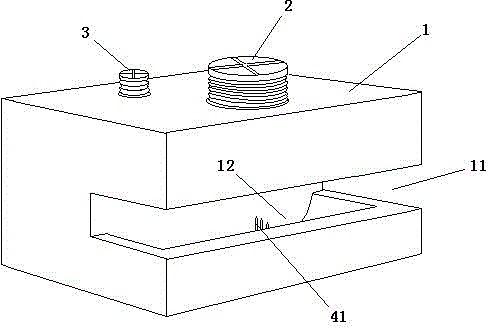

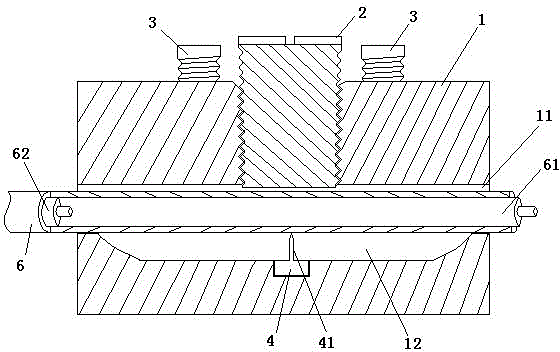

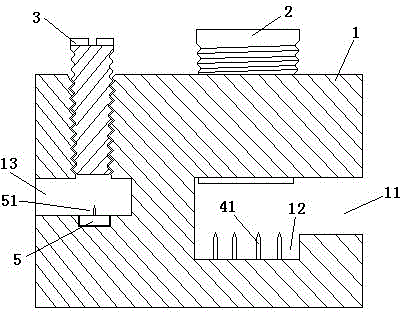

[0013] Such as figure 1 As shown, the quick connection terminal housing 1 of this embodiment is a rectangular block structure made of engineering plastics. A groove 11 is opened in the front and back on the right side. The cross section is similar to the inverted concave on the right side. The groove 11 is The height is just to snap into the twin-core wire 6 of the corresponding specification, and a pit 12 is also opened on the bottom surface of the groove 11, the width is equal to the parallel width of the twin-core wire 6, so that it can be squeezed into it in parallel. Combine figure 2 with image 3 As can be seen from the cross-sectional structure diagram, on the top surface of the terminal housing corresponding to the groove 11 and the pit 12, there is a bus fastening bolt 2 that vertically leads to the groove 11 and the pit 12; at the bottom of the corresponding bolt On the bottom surface of the pit 12, there are two sets of four horizontally arranged bus terminal pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com