Two-speed variable speed electric vehicle rear axle reducer assembly with electromagnetic two-way clutch

A two-way clutch and reducer technology, applied in the direction of components with teeth, instruments, transmission devices, etc., can solve the problems of three guarantees and difficult maintenance, poor climbing ability, weak climbing ability, etc., to improve the wide range of applications. performance, extended battery life, and the effect of increasing cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

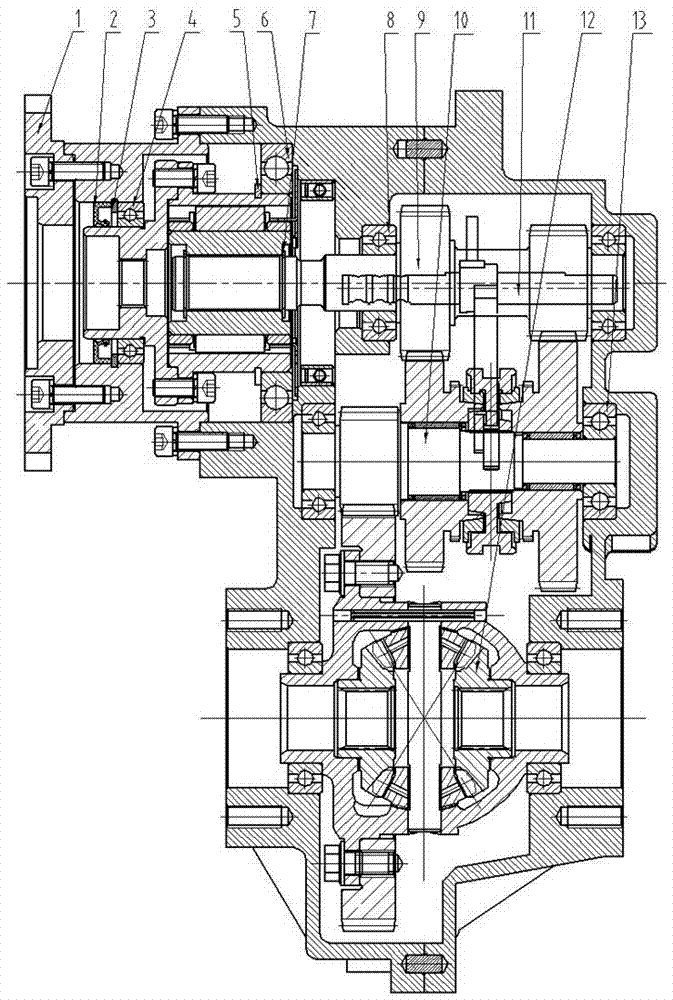

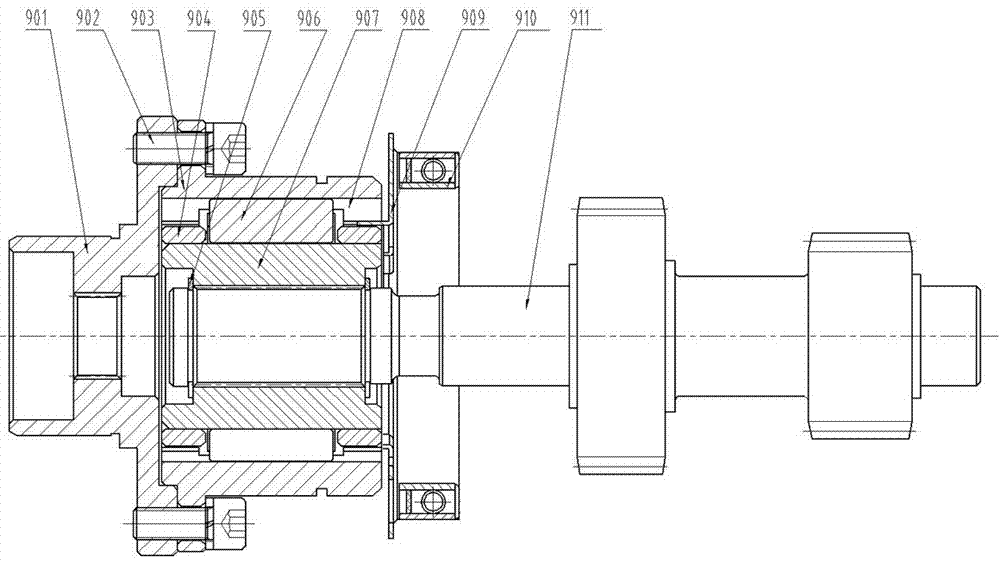

[0022] The embodiment of the present invention provides a two-speed variable speed electric vehicle rear axle reducer assembly with an electromagnetic two-way clutch, such as Figure 1~6 As shown, the reducer assembly includes: a reducer housing 1, an electromagnetic two-way clutch 9, a two-stage deceleration high and low gear pair 10, a shift shaft assembly 11, and a differential assembly 12. The reducer housing 1. An electromagnetic two-way clutch 9 is arranged on one side of the inner top, and the electromagnetic two-way clutch 9 is connected with the shift shaft assembly 11 arranged on the other side. The pair 10 meshes, and the two-stage reduction high and low gear pair 10 meshes with the differential assembly 12 arranged at the bottom.

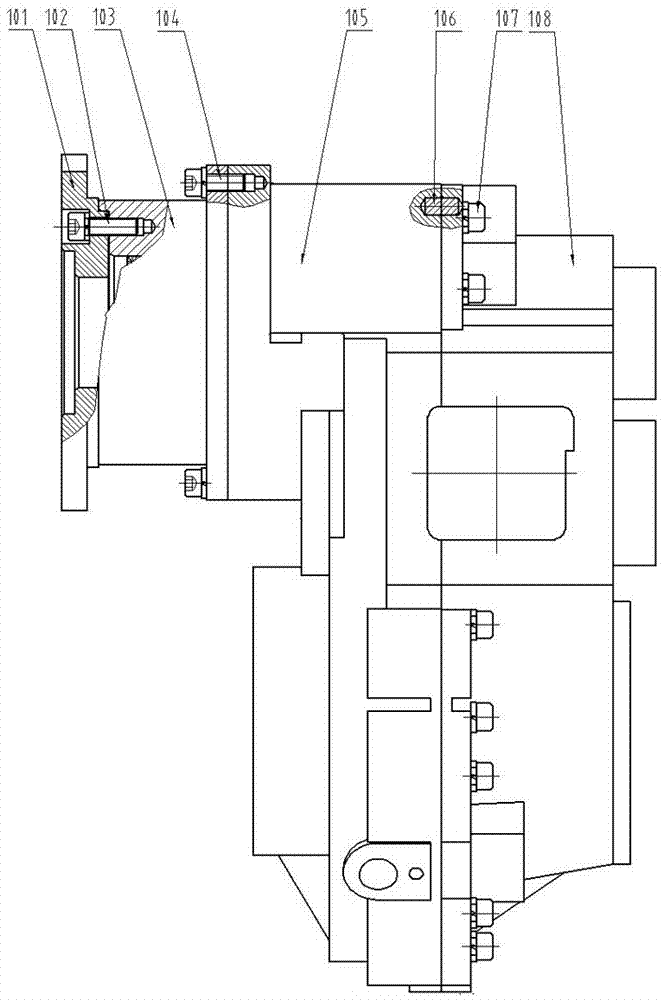

[0023] Such as figure 2 As shown, the reducer housing 1 includes a motor flange 101, a connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com