Diesel engine with synchronous fluctuation rooms

A technology of diesel engines and wave chambers, which is applied to engine components, machines/engines, mechanical equipment, etc., and can solve problems such as slow vaporization fluid speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below by specific embodiment:

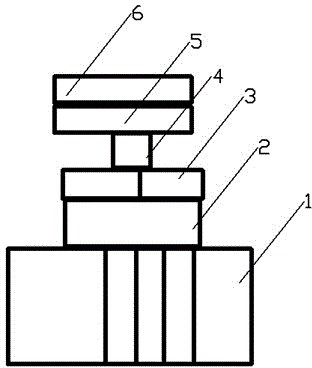

[0010] Such as figure 1 As shown, a diesel engine with a synchronous wave chamber includes a single vaporized fluid screen device 3 connected to the vaporized fluid intervening end 2 of the diesel engine 1, and a single main synchronous wave chamber 4 input to the vaporized fluid screen device 3 Enter the vaporization fluid channel 5 of the single-channel vaporization fluid. The vaporization fluid channel 5 is attached with a single auxiliary synchronous wave chamber 6 .

[0011] The working principle of the present invention is that through a single vaporized fluid screen device 3 connected to the vaporized fluid intervening end 2 of the diesel engine 1, there is also a single channel vaporized fluid input to the main synchronous wave chamber 4 of the vaporized fluid screen device 3 The vaporization fluid channel 5. The vaporization fluid channel 5 is attached with a single auxiliary syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com