soil sampler

A technology of sampler and soil, which is applied in the direction of sampling device, etc., can solve the problem of sampling soil pushing out, and achieve the effect of avoiding secondary sampling, ensuring the plugging effect and improving the success rate of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

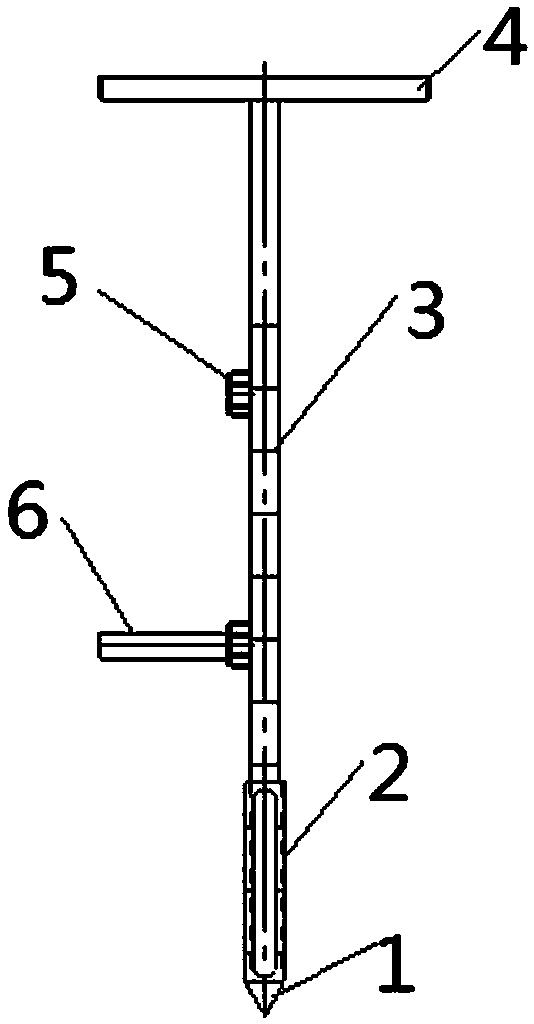

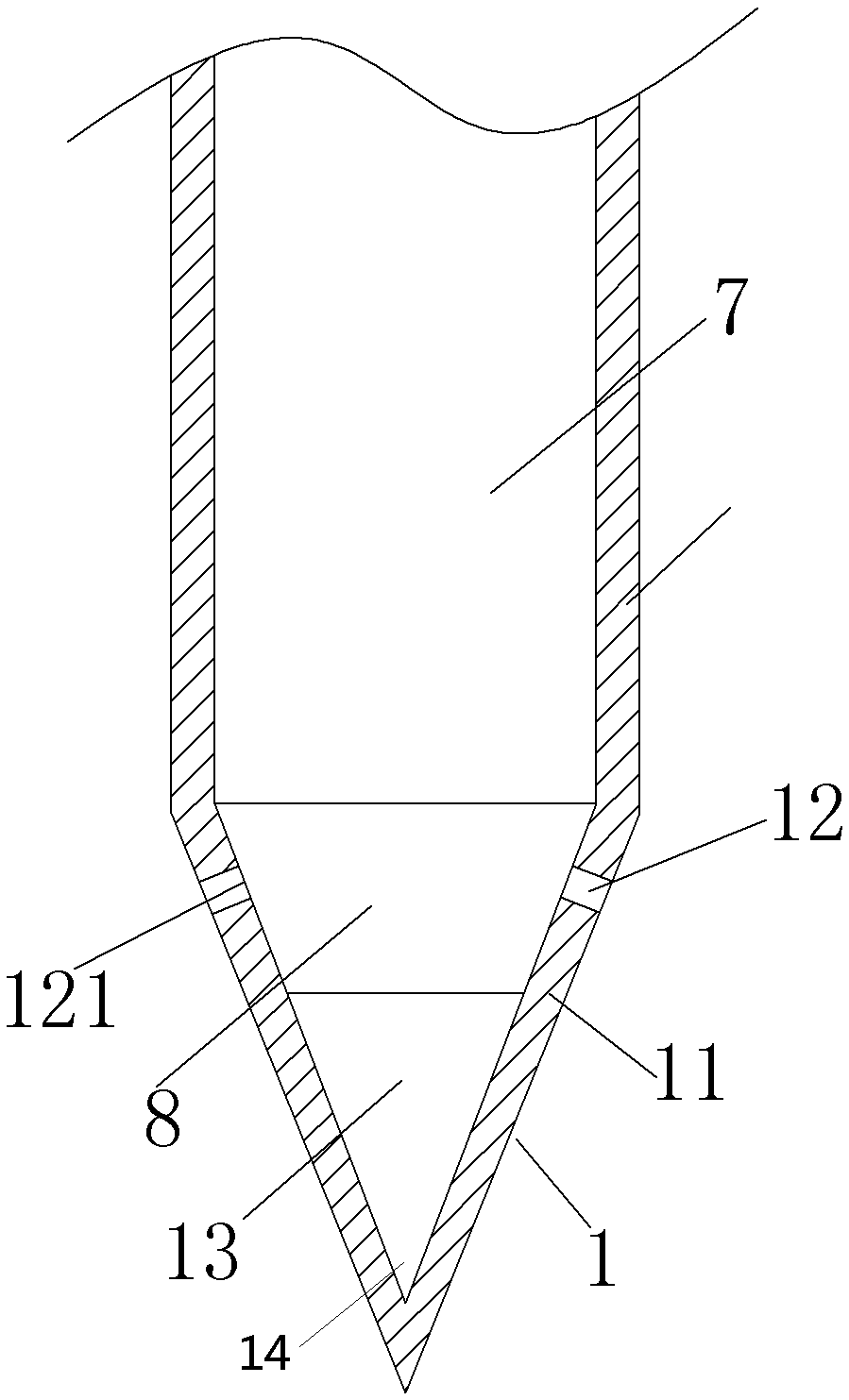

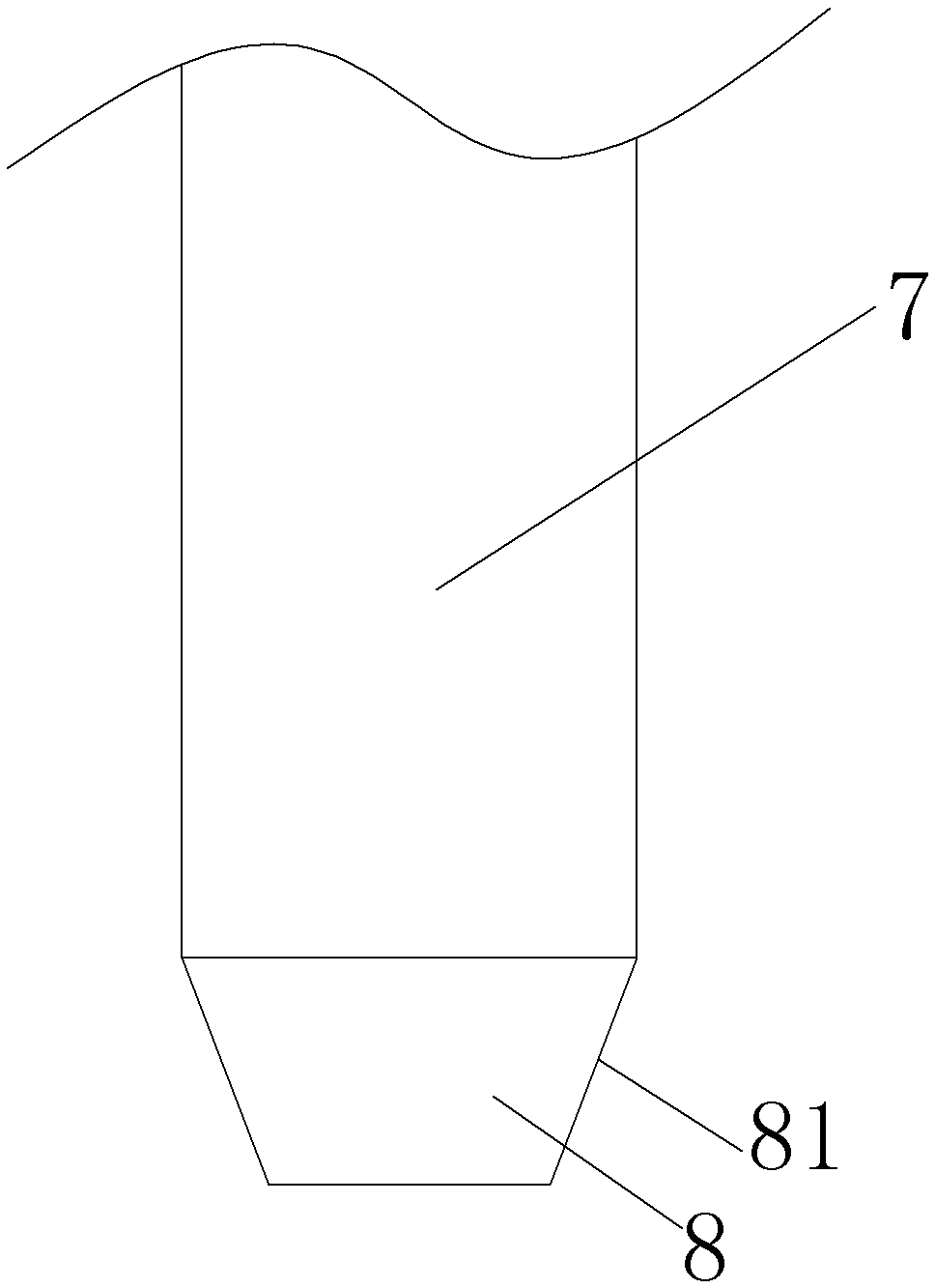

[0026] Such as Figure 1 to Figure 3 Shown, a kind of embodiment of soil sampler, the soil sampler in this embodiment comprises outer tube 2, and outer tube 2 bottom is provided with hollow sampling head 1, and the bottom of sampling head is sealing structure, and sampling head 1 has for The circumferential side wall 11 of the hollow cavity 13 is formed. The circumferential side wall 11 of the sampling head 1 is a conical side wall with a large top and a small bottom. On the circumferential side wall 11 of the sampling head 1, there is a The sampling holes 12 communicated with the cavity 13, the sampling holes 12 are evenly distributed around the sampling head circumferential direction, and the sampling holes 12 have an inner orifice 121 extending to the inner wall surface of the circumferential side wall 11 facing the hollow inner cavity 13, the inner orifice 121 is higher than the bottom of the hollow inner cavity 13 in the vertical direction, where the bottom of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com