Lighting fixture for backlight and defect detection equipment using it

A lighting fixture and backlight technology, which is applied in the direction of optical testing defects/defects, optics, nonlinear optics, etc., can solve the problems of high development cost, long development cycle, and many types of lighting fixtures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

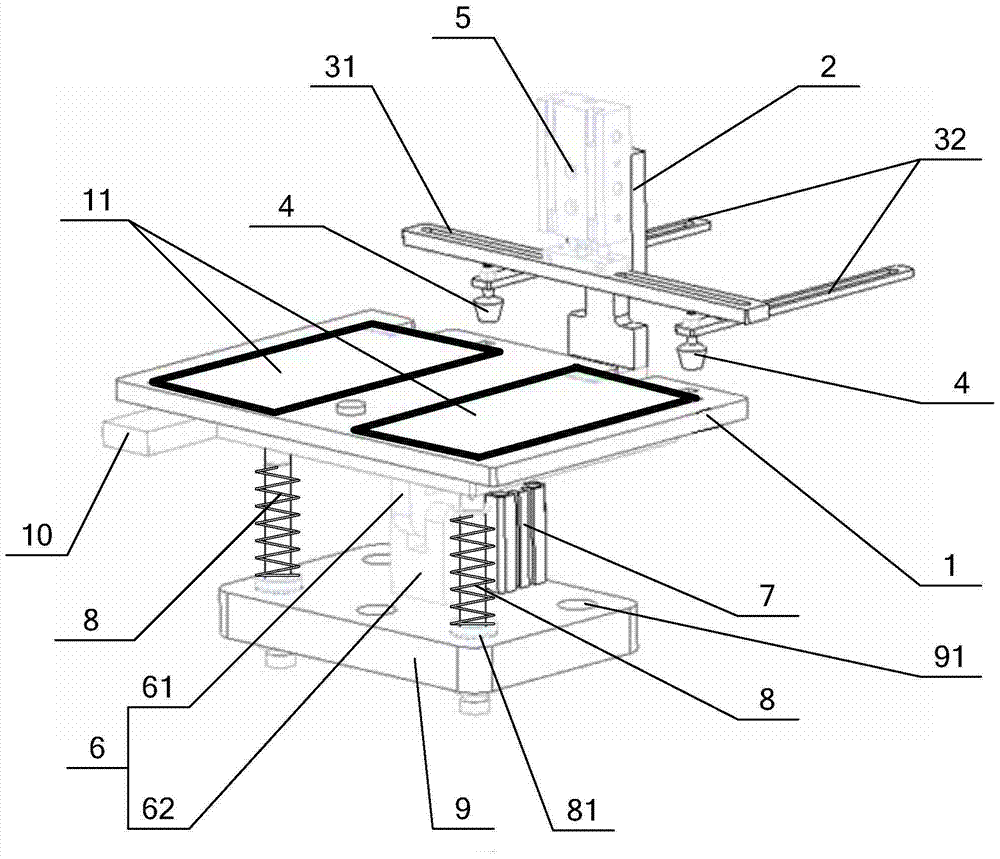

[0020] A lighting fixture for a backlight provided by an embodiment of the present invention and a defect detection device using the same will be described in detail below with reference to the accompanying drawings.

[0021] An embodiment of the present invention provides a lighting fixture for a backlight source, such as figure 1 As shown, it includes the jig body 1, and the jig body 1 is provided with a detection area for placing the backlight (the area shown in the thick line in the figure); the jig body 1 is also fixed with a bracket 2, and the bracket 2 is provided with a longitudinal Adjusting rod 31, vertical adjusting rod 31 is movably connected with horizontal adjusting rod 32, and one end of horizontal adjusting rod 32 is fixed with pressure head 4; Longitudinal adjusting rod 31 can move up and down along support 2 to drive horizontal adjusting rod 32 up and down Moving, the horizontal adjustment rod 32 can move forward, backward, left and right in the horizontal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com