Shielding sliding shoe curvilinear pushing-up hole-passing construction method

A construction method and technology of sliding shoes, which are applied in earth square drilling, mining equipment, mining equipment, etc., to achieve the effect of saving material, saving the amount of empty push material, and good line shape control function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] The present invention is aimed at shield tunneling through the mine method tunnel that has been lined, and its specific implementation method is as follows:

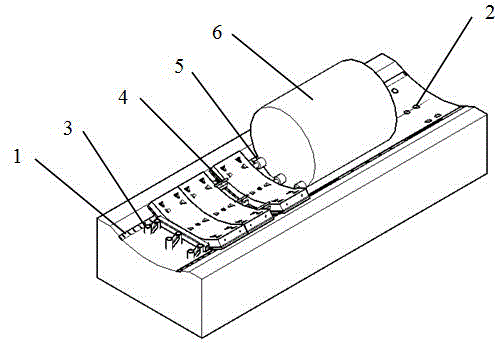

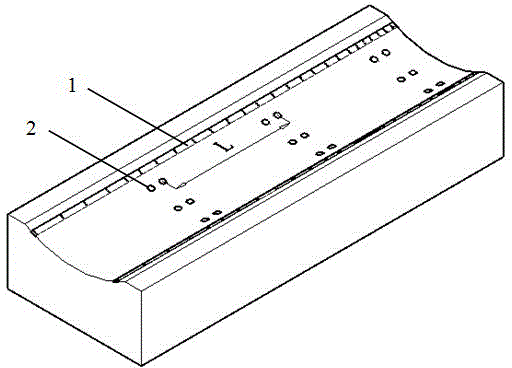

[0045] Such as figure 1 with figure 2 As shown, two side-by-side steel plates are installed on the concrete guide platform of the mining method tunnel. The steel plates are fixed on the concrete guide platform with embedded self-anchoring bolts, and the uneven position of the bottom of the plate is filled with steel material support pads. The steel plates are installed in sections according to the jacking degree, and are reused; the two steel plates installed side by side are the sliding shoes 1 for the shield machine 6 to travel; butter is applied to the surface of the laid steel sliding shoes 1 .

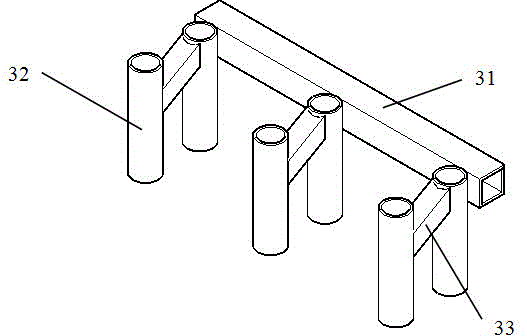

[0046] The core-pulling method is used to drill the counter force hole 2 in the middle of the slide shoe 1, and two rows are arranged according to the jacking force, and each row has three counter force holes 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com