Modeling and optimization method of natural gas purification process based on unscented Kalman neural network

An unscented Kalman and neural network technology, applied in the field of intelligent energy saving and production increase, can solve problems such as the quality and inconsistency of difficult target problems, and achieve the goals of realizing energy consumption and production, improving model accuracy, and improving modeling accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

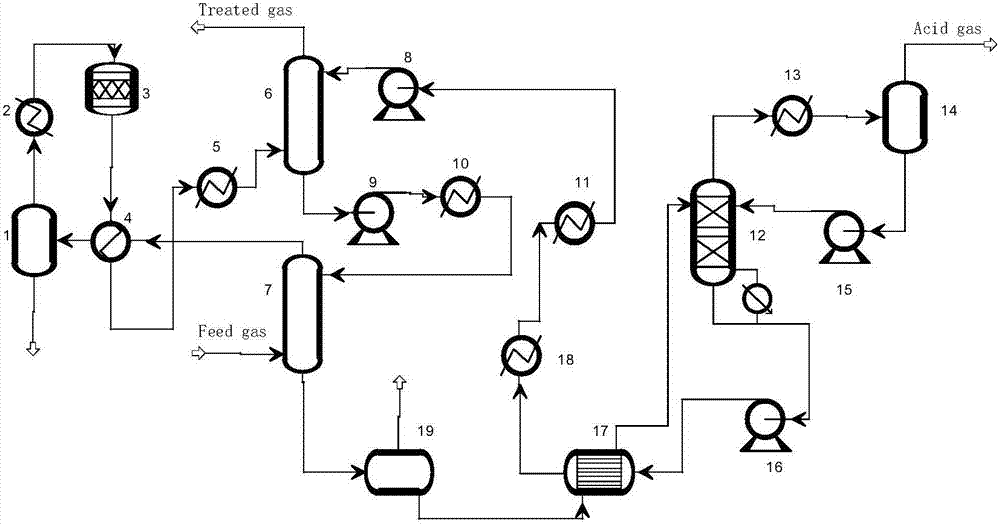

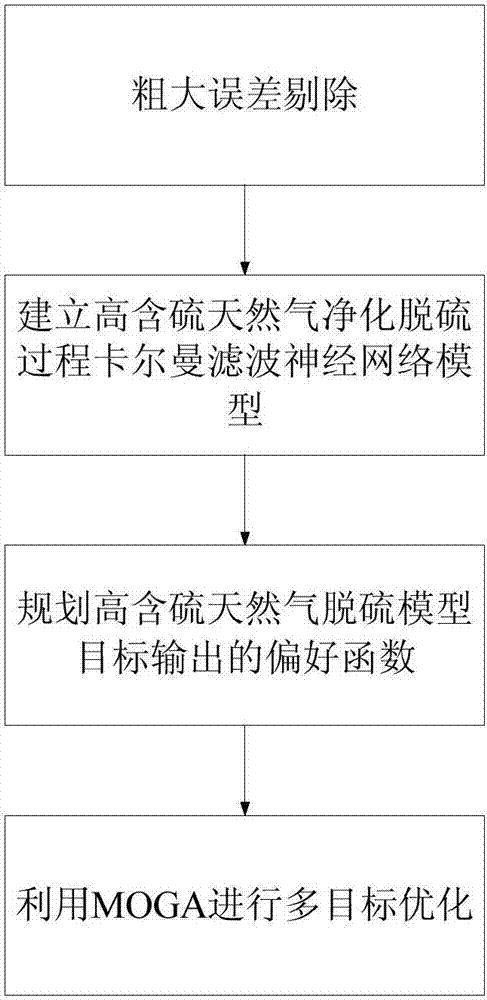

[0053] see image 3 , a natural gas purification process modeling optimization method based on unscented Kalman neural network, characterized in that the method is carried out as follows:

[0054] Step 1: Determine the input variables of the high-sulfur natural gas purification and desulfurization process model: select m process operation parameters that can be effectively controlled during the production process of the high-sulfur natural gas purification and desulfurization process as model input variables, where m=10, input The variables are: x 1 Indicates the inlet flow rate of the desulfurization absorption tower amine liquid, x 2 Indicates the inlet flow rate of tail gas absorption tower amine liquid, x 3 Indicates the raw material gas processing capacity, x 4 Indicates the circulating volume of semi-rich amine solution, x 5 Indicates the inlet temperature of the primary absorption tower amine liquid, x 6 Indicates the inlet temperature of the secondary absorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com