Abnormity detection and diagnosis method for non-gaussian dynamic high-sulfur natural gas purification process

A process abnormality and diagnostic method technology, applied in the direction of electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as failure to detect failures in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

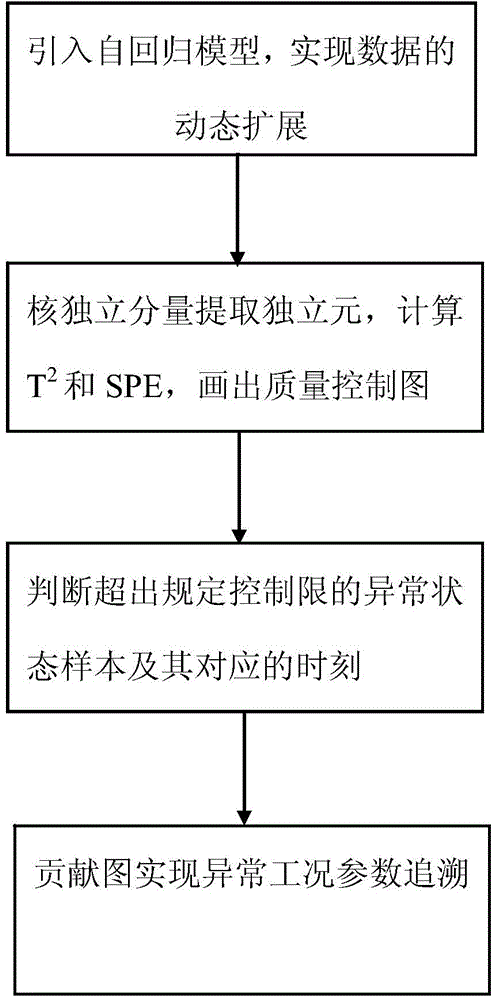

[0049] Such as figure 1 As shown, a non-Gaussian dynamic high-sulfur natural gas purification process abnormal detection and diagnosis method is carried out according to the following steps:

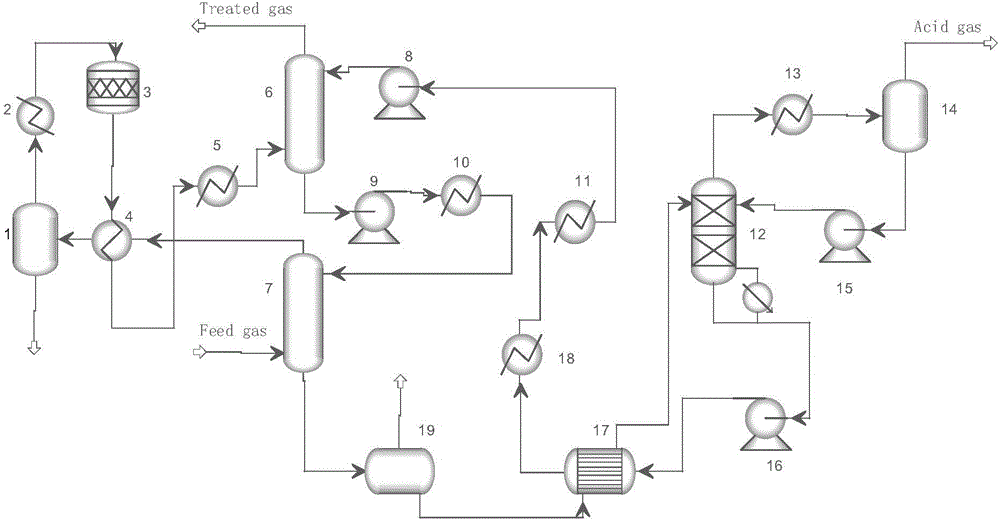

[0050] Step 1: Randomly collect n groups of high-sulfur natural gas purification process data to form the original measurement sample set X=[x 1 ,x 2 ,...,x n ]∈R m×N , each sample contains N independent high-sulfur natural gas purification process parameter sampling values.

[0051] Step 2: Preprocess the sample data and select the effective data that can best reflect the actual characteristics of the production process; specifically: eliminate samples with missing parameters in the collected data, and ensure that the samples meet the company's purification gas technical indicators, and the obtained data is X *=[x 1 ,x 2 ,...,x n ]∈R m×n , n is the number of samples collected after processing, n<N.

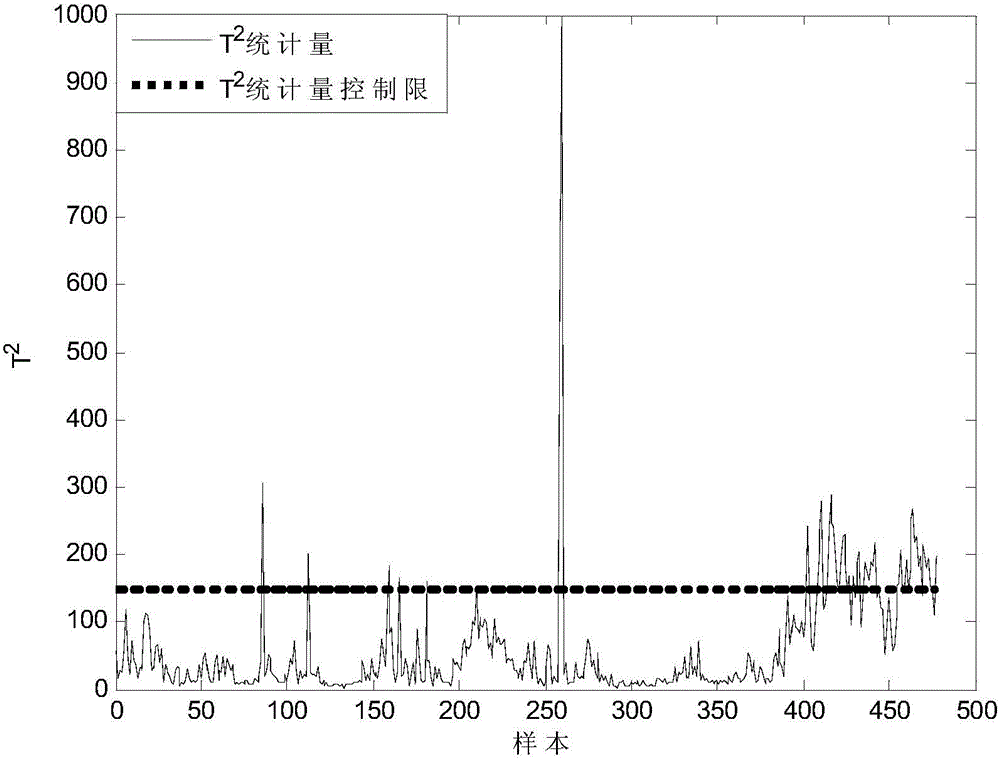

[0052] Step 3: Analyze the autoregressive model of the data X* obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com