A formwork assembly for lining corbels in tunnel construction and its construction method

A technology of tunnel construction and formwork, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc. It can solve the problems of uncontrollable corbel structure pouring quality, poor overall performance of corbel structure, and poor pouring molding quality, so as to save manpower, remove The effect of large mold space and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

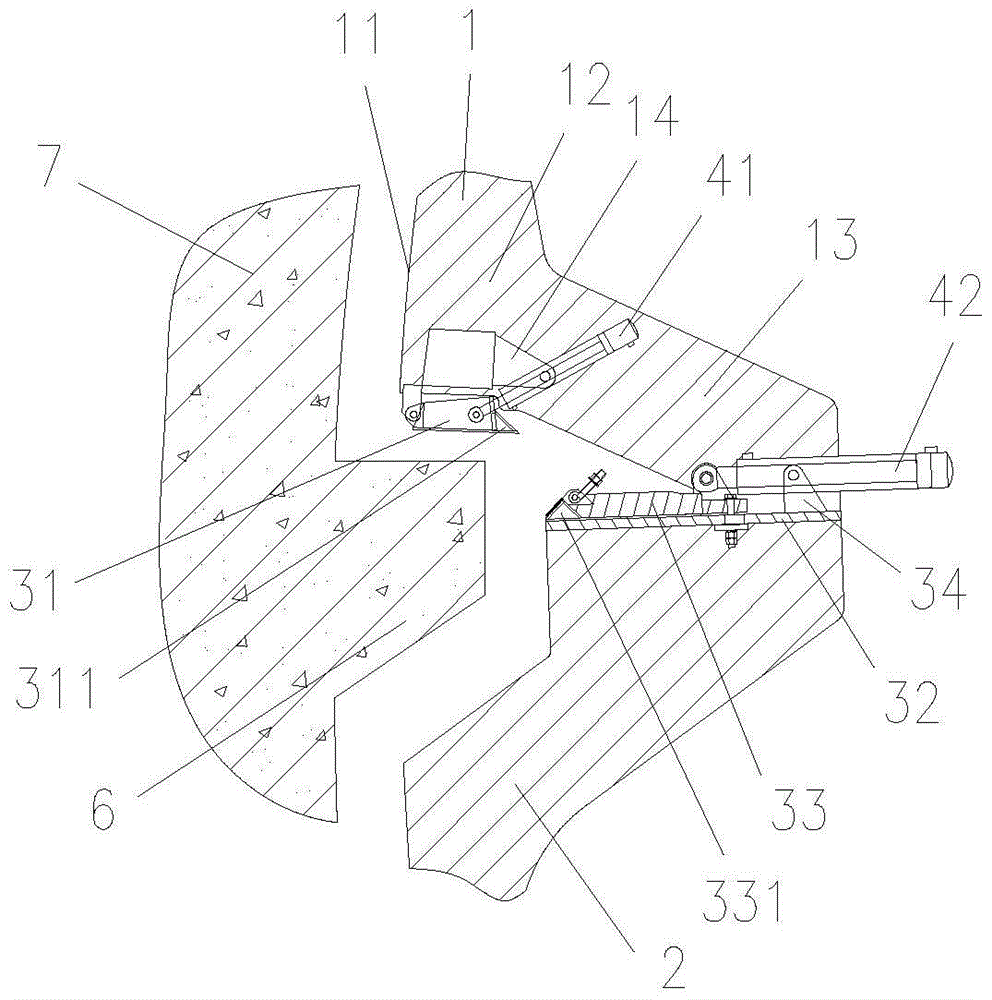

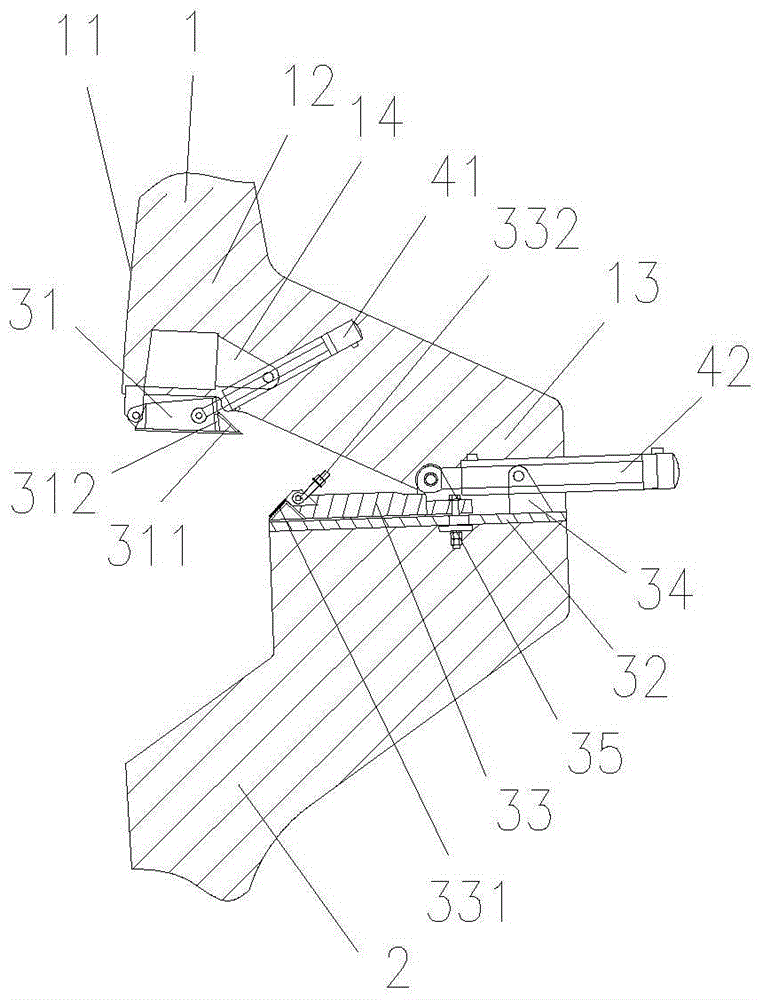

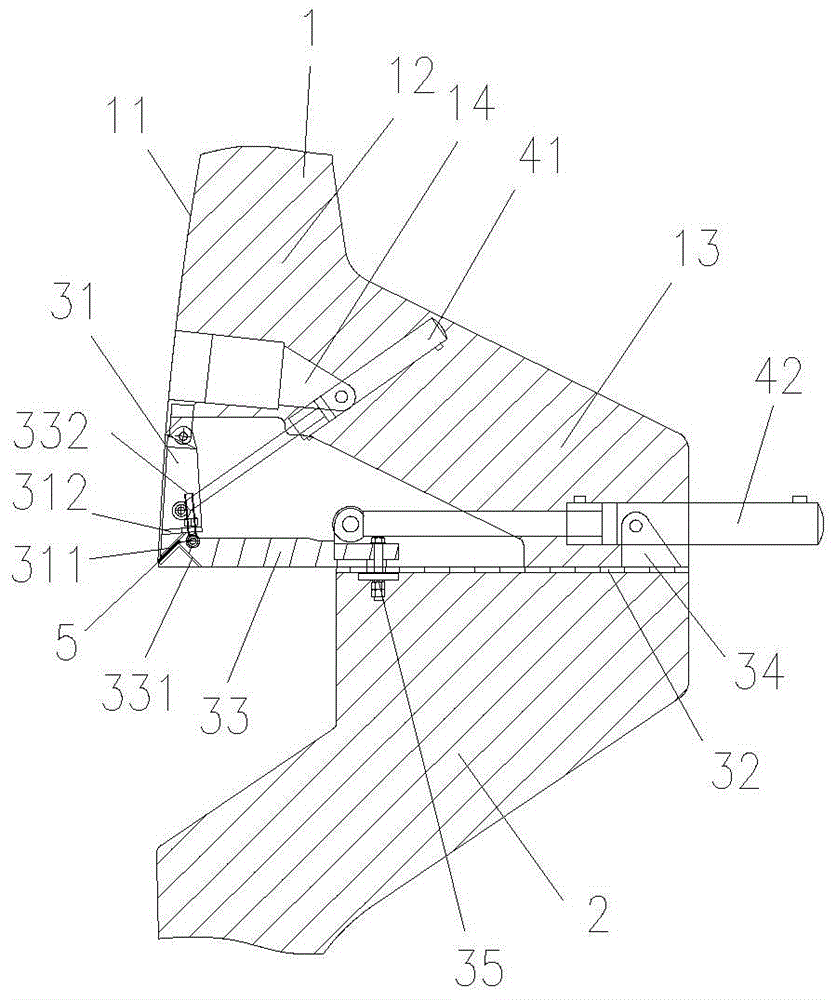

[0037] A formwork assembly for lining corbels in tunnel construction, see figure 1 , figure 2 , image 3 as well as Figure 4, specifically: the formwork assembly includes a first lining formwork 1 and a second lining formwork 2 arranged from top to bottom (it can be best seen in the sectional view of the formwork assembly along the width direction of the corbel), so The first lining formwork 1 and the second lining formwork 2 are provided with an adjustable formwork group, and after the mold is erected, the adjustable formwork group and the second lining formwork 2 form a cavity that matches the corbel structure, Through the adjustment of the adjustable formwork, a mold cavity matching the corbel structure can be formed with the first lining formwork 1 and the second lining formwork 2, and the operation is convenient.

[0038] The first lining formwork 1 is composed of a first section 12 that can be placed close to the inner wall of the tunnel 7 when lining the corbel 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com