Implementation method for equivalently loading incident wave in double-shaft split Hopkinson pressure bar and pull rod experiments

A technology of Hopkinson pressure bar and incident wave, applied in the field of effective loading, which can solve problems such as capacitance error, different pulse width, and asynchronous loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

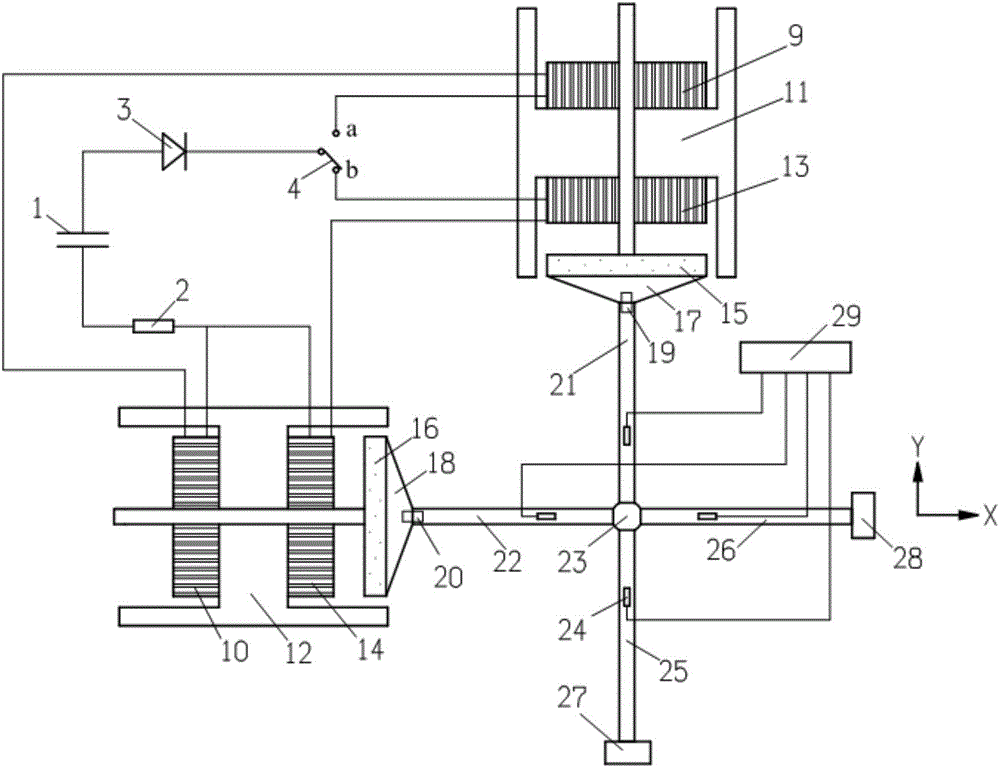

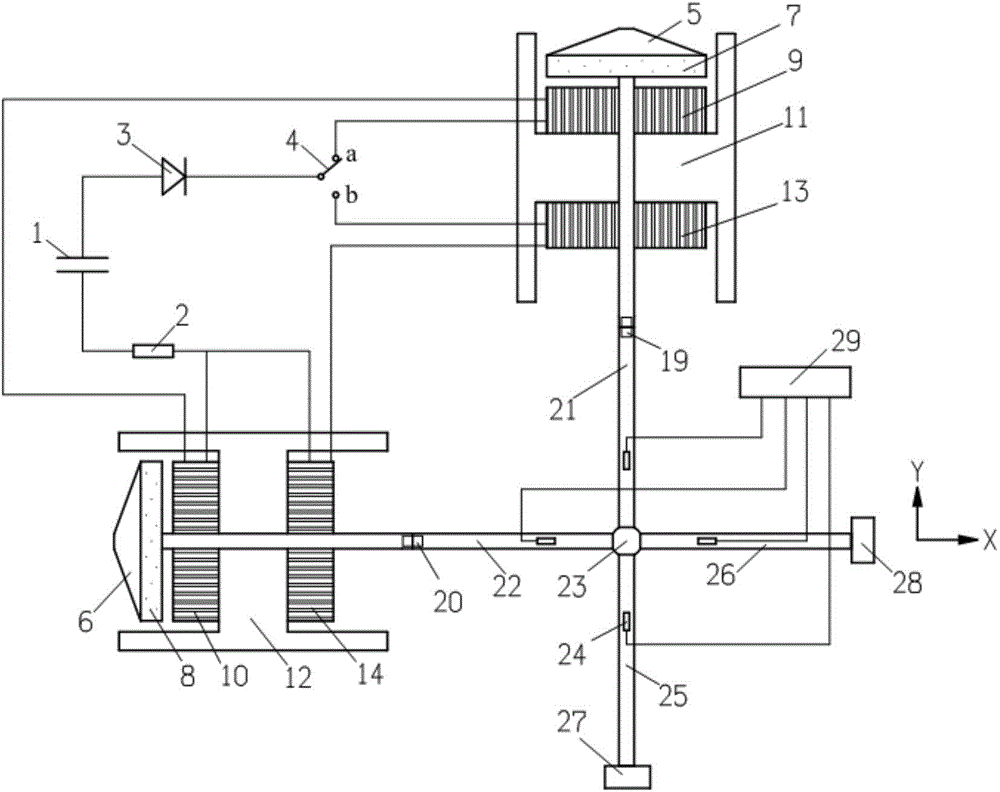

[0057] refer to Figure 1-8 . The specific steps of the method for realizing the equivalent loading of the incident wave in the biaxial Hopkinson compression bar and tie bar experiment of the present invention are as follows:

[0058] 1. Arrangement of longitudinal and transverse incident wave generators.

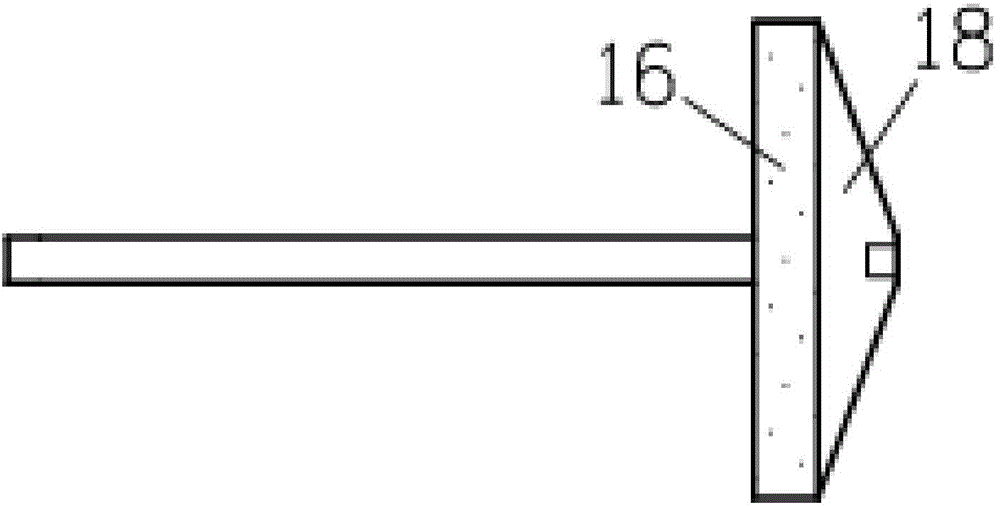

[0059]The longitudinal compression wave secondary coil 15 is connected to the longitudinal compression wave amplifier 17 by bolts to form a longitudinal compression wave drive head; the transverse compression wave secondary coil 16 is connected to the transverse compression wave amplifier 18 by bolts to form a transverse compression wave drive head; The longitudinal stretching wave secondary coil 7 is connected to the longitudinal stretching wave amplifier 5 by bolts to form a longitudinal stretching wave drive head; the transverse stretching wave secondary coil 8 is connected to the transverse stretching wave amplifier 6 by bolts to form a transverse stretching wave drive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap