Lens assembly, light supplementing assembly and camera with light supplementing assembly

A component and lens technology, applied in the field of cameras, can solve the problems of less than ideal illuminance and uniformity, and achieve the effect of better uniformity of supplementary illuminance and high utilization rate of luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

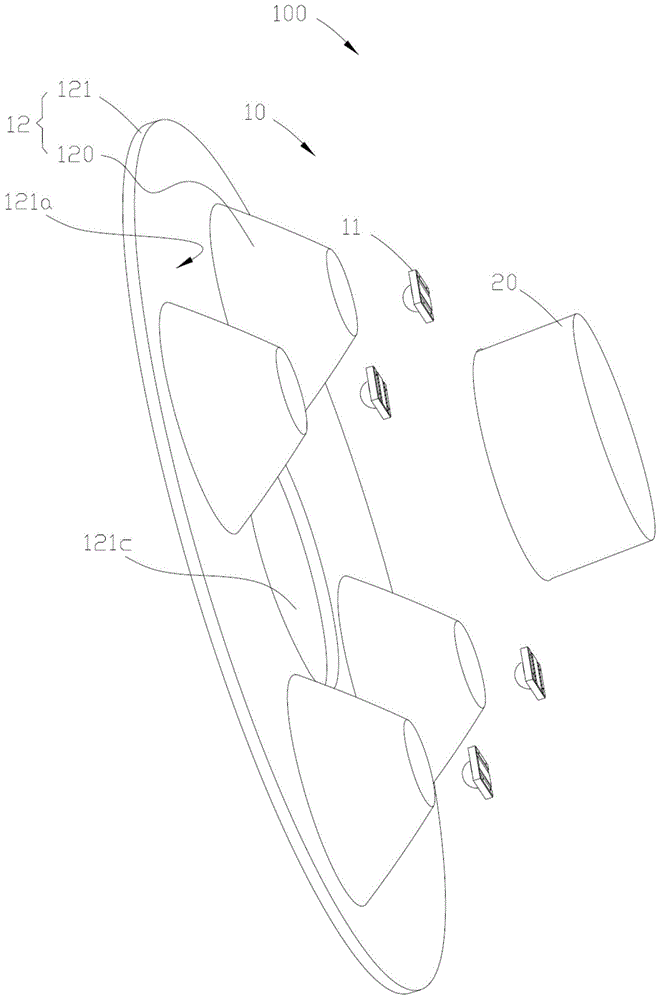

[0024] Please also refer to figure 1 and figure 2 , a camera 100 provided in an embodiment of the present invention, the camera 100 includes a supplementary light assembly 10 and a lens 20 . The supplementary light assembly 10 supplements light for the lens 20 .

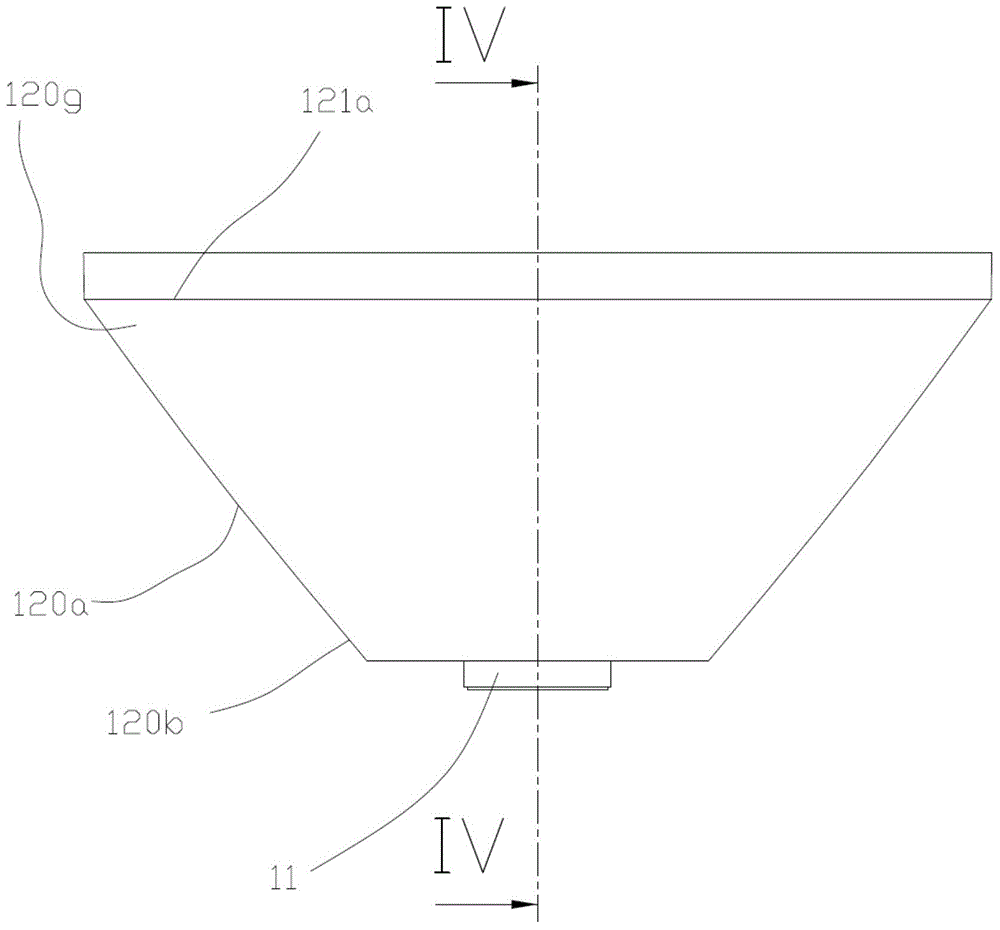

[0025] The supplementary light assembly 10 includes four light sources 11 and a lens assembly 12 . Of course, in other implementation manners, the supplementary light assembly 10 may also include 2, 3 or more of the light sources 11 . The lens assembly 12 includes four light distribution modules 120 and a transparent plate 121 .

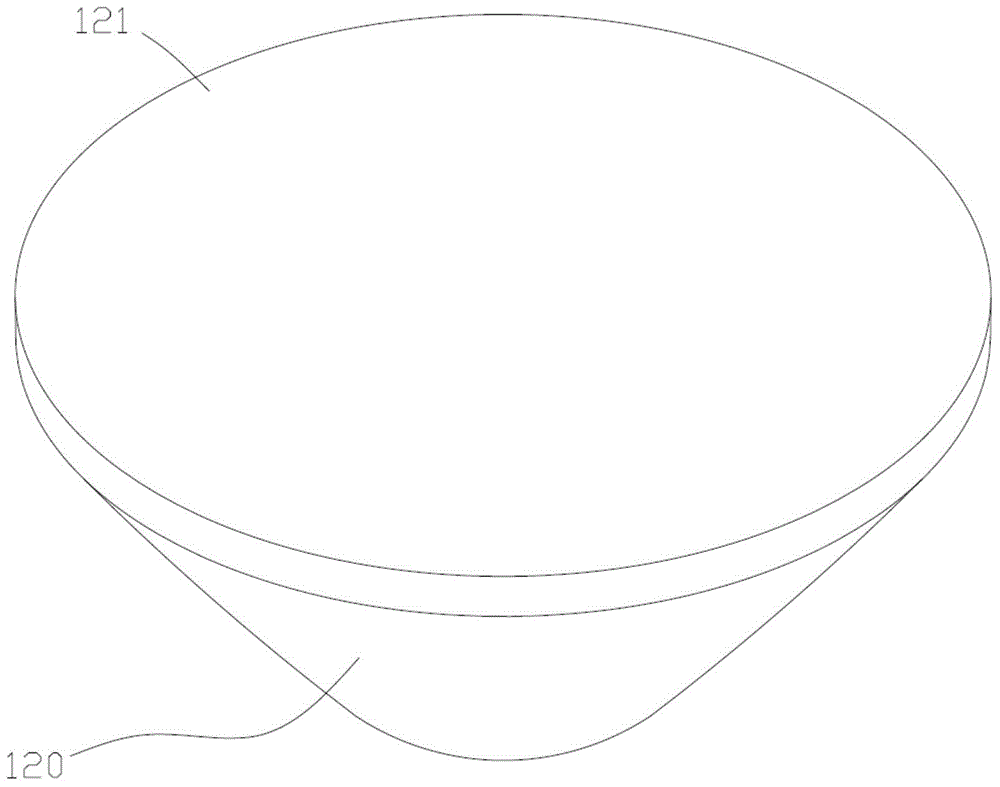

[0026] The transparent plate 121 includes two opposite disk surfaces 121a, and the transparent plate 121 defines a light-transmitting hole 121c passing through the two disk surfaces 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com