Manipulator with four motion ranges in gear transmission space

A four-movement, gear-driven technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of bloated robot structure and large footprint, and achieve compact overall structure, small footprint, and small inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

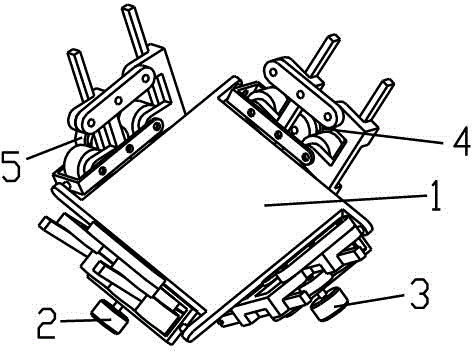

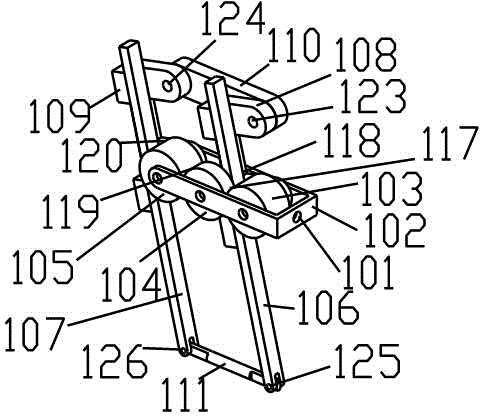

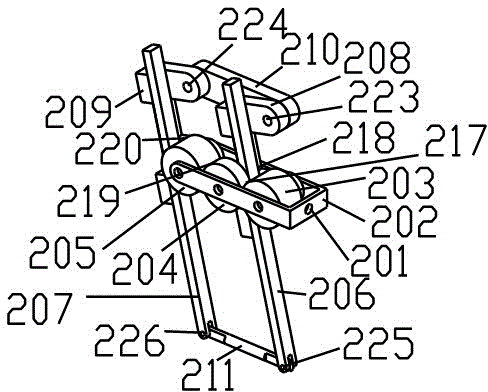

[0030] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 , the four-degree-of-motion manipulator in the gear transmission space, including the frame 1, the first branch chain, the second branch chain, the third branch chain, the fourth branch chain, the first motor 2, the second motor 3, the third motor 4, the Four motors 5 and a moving table mechanism.

[0031] The first bracket 102 of the first branch chain is connected with the frame 1 through the first rotation pair 101, and the first connecting shaft 111 of the first branch chain is connected with the first translation rod of the translation platform mechanism through the second rotation pair 505 501 connection, the second bracket 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com