Hydraulic synchronization oil channel structure with bi-directional oil replenishing and discharging function

A hydraulic synchronization and synchronous oil cylinder technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of inconvenient use and maintenance, to ensure timeliness and high efficiency, reduce difficulty, and ensure oil quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

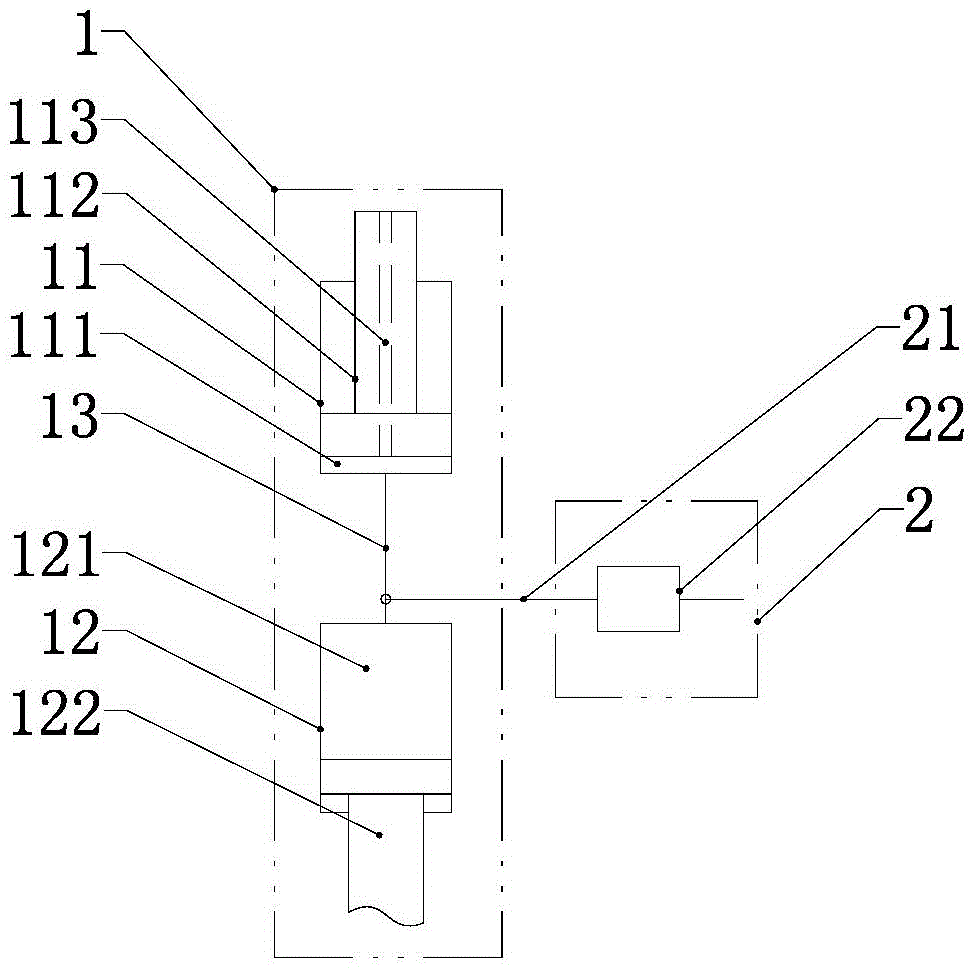

[0021] Such as figure 2 As shown, the hydraulic synchronous oil circuit structure described in this embodiment is also composed of a synchronous oil cylinder group 1 and an oil replenishment and discharge mechanism 2, wherein the structure and principle of the synchronous oil cylinder group 1 are the same as figure 1 Same as shown.

[0022] The oil replenishment and discharge mechanism 2 described in this embodiment is mainly composed of two replenishment and discharge oil passages 21 and two function switches 22: the connection port of one of the replenishment and discharge oil passages 21 is set on the cylinder wall of the ejection cylinder 11 , the connecting port of the other replenishment and discharge oil passage 21 is arranged on the cylinder wall of the synchronous oil cylinder 12 . The two function switches 2 are respectively arranged on a replenishment and discharge oil passage 21, and the function switches can be hydraulic valves, plugs or blocks; moreover, the fu...

Embodiment 2

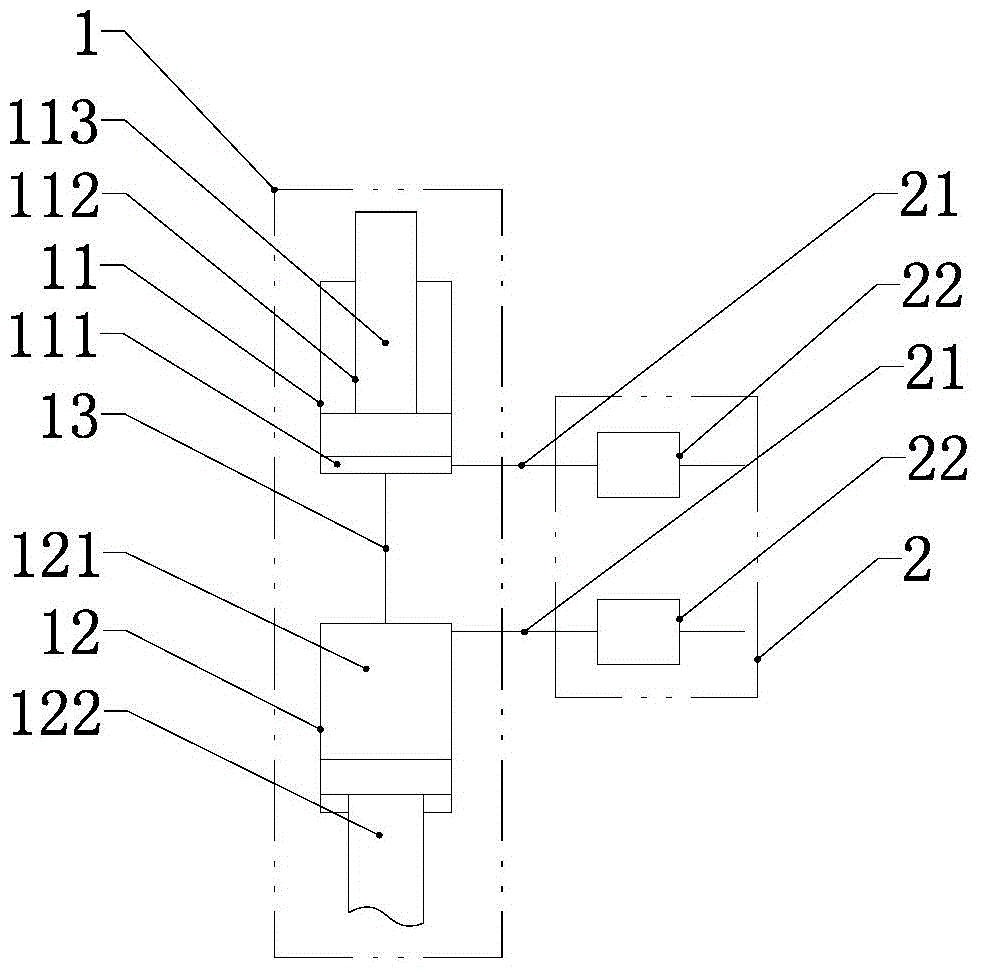

[0027] The composition of the hydraulic synchronous oil circuit structure described in this embodiment is the same as that of Embodiment 1, the difference is that the connection port of one of the replenishment and discharge oil passages 21 is set on the cylinder bottom of the ejection cylinder 11, and the other is the connection port of the replenishment and discharge oil passage 21. The connecting port of the road 21 is arranged on the cylinder bottom of the synchronous oil cylinder 12 .

[0028] The working principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

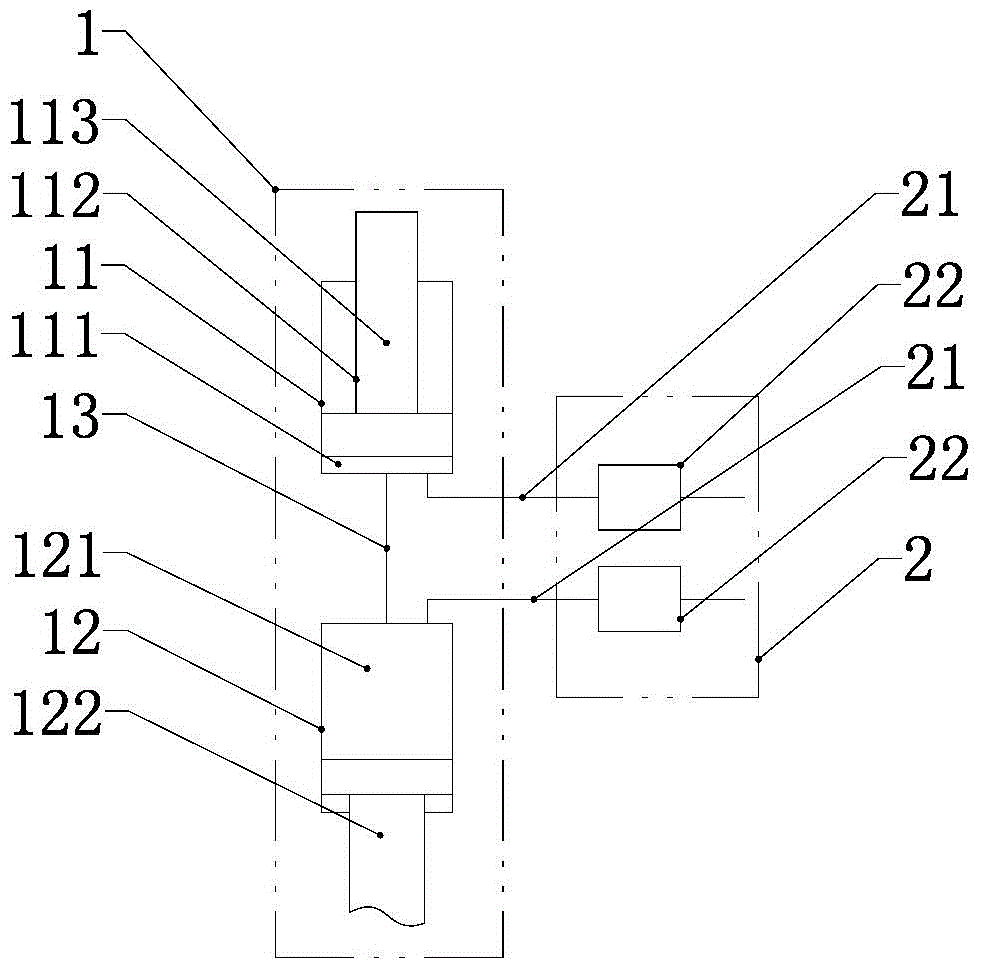

[0030] The composition of the hydraulic synchronous oil passage structure described in this embodiment is the same as that of Embodiment 1, the difference is that the connection port of one of the replenishment and discharge oil passages 21 is set on the synchronization oil passage 13, and the connection port of the other supplementary and discharge oil passage 21 The connecting port is arranged on the synchronous oil passage 13.

[0031] The working principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com