Lamp bulb durability testing device

A test device and durability technology, applied in the field of lighting, can solve problems such as the failure of the light source to work normally, the damage of metal friction, and the inability to guarantee the reliability of the light source lamp head of the lamp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

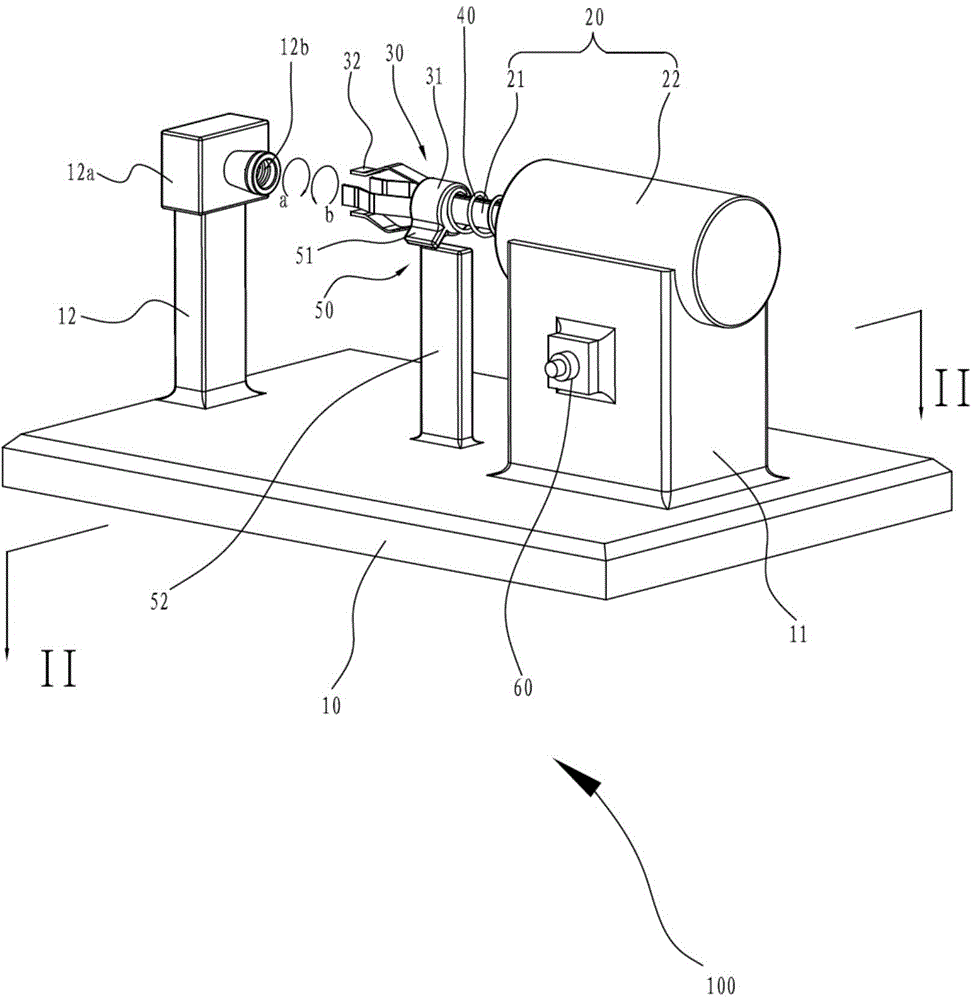

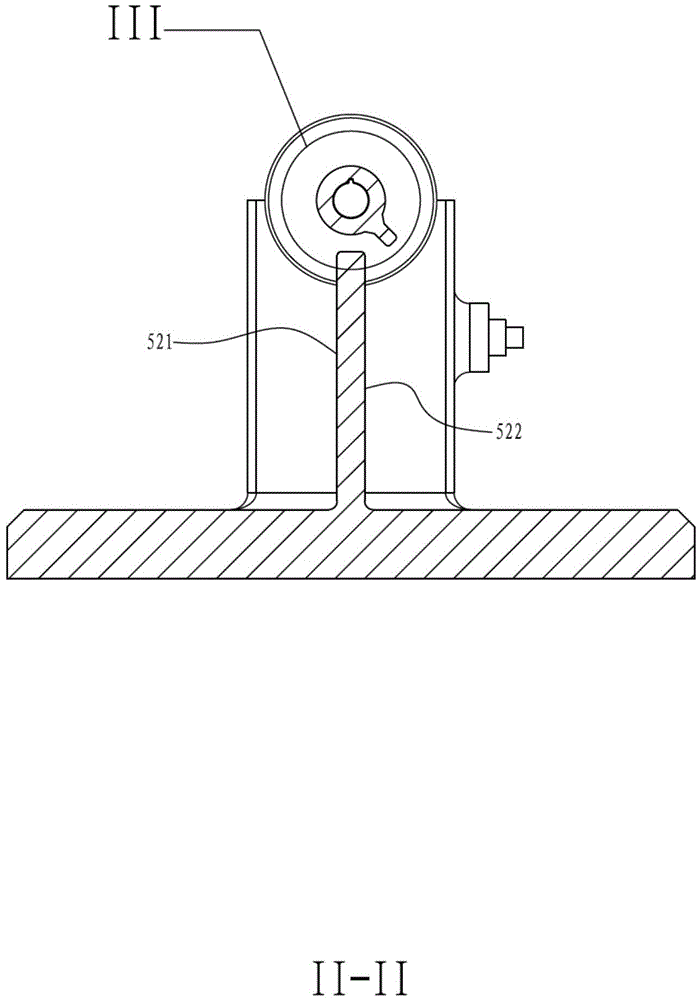

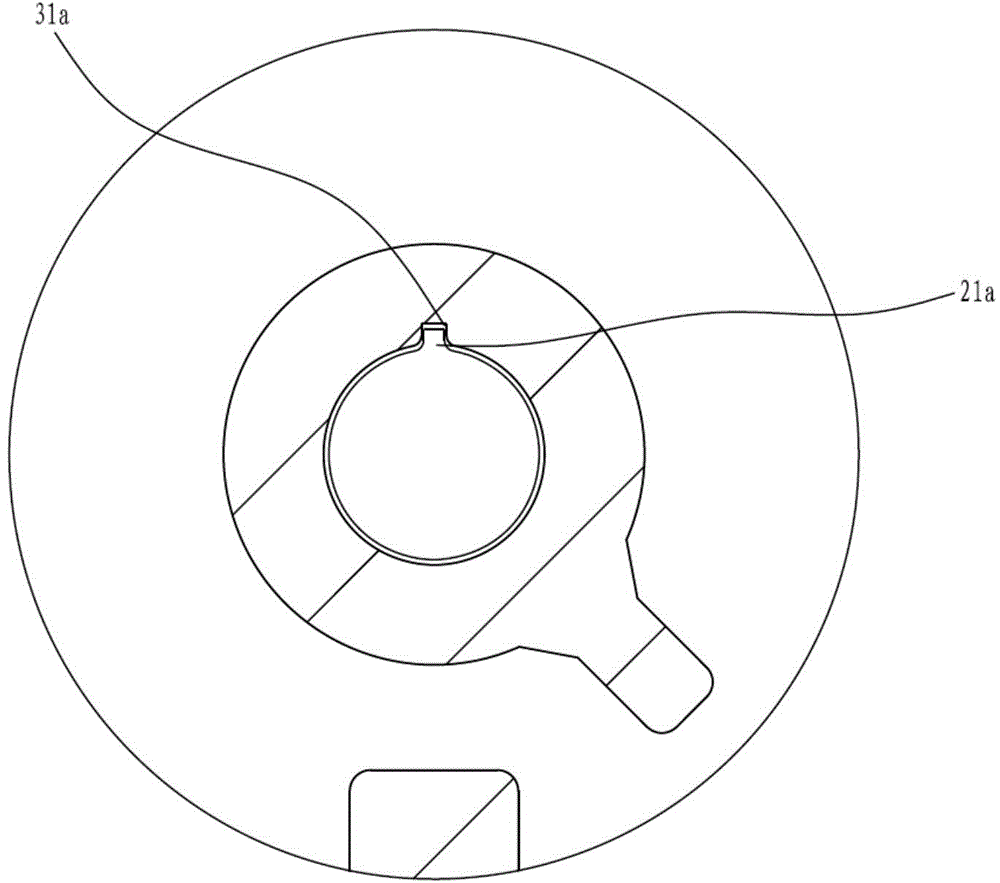

[0020] Please also refer to figure 1 , figure 2 and image 3 , a light bulb durability test device 100 provided in an embodiment of the present invention is used to test the durability of a light bulb (not shown), and the light bulb includes a threaded lamp cap (not shown) and a light emitting part (not shown) ). The light bulb durability testing device 100 includes a bottom plate 10 , a driving mechanism 20 , a clamping member 30 , a first elastic member 40 and a limiting mechanism 50 . The driving mechanism 20 drives the clamping part 30 to rotate, the clamping part 30 clamps the light bulb, and the first elastic part is compressed between the clamping part 30 and the driving mechanism 20, so that the clamping part 30 Clamp the bulb to reset. The limiting mechanism 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com