Main frame strength calculation method of wind generator set

A technology for wind turbines and strength calculation, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of wasting materials, increasing structural size, and bulky main frame design, saving time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

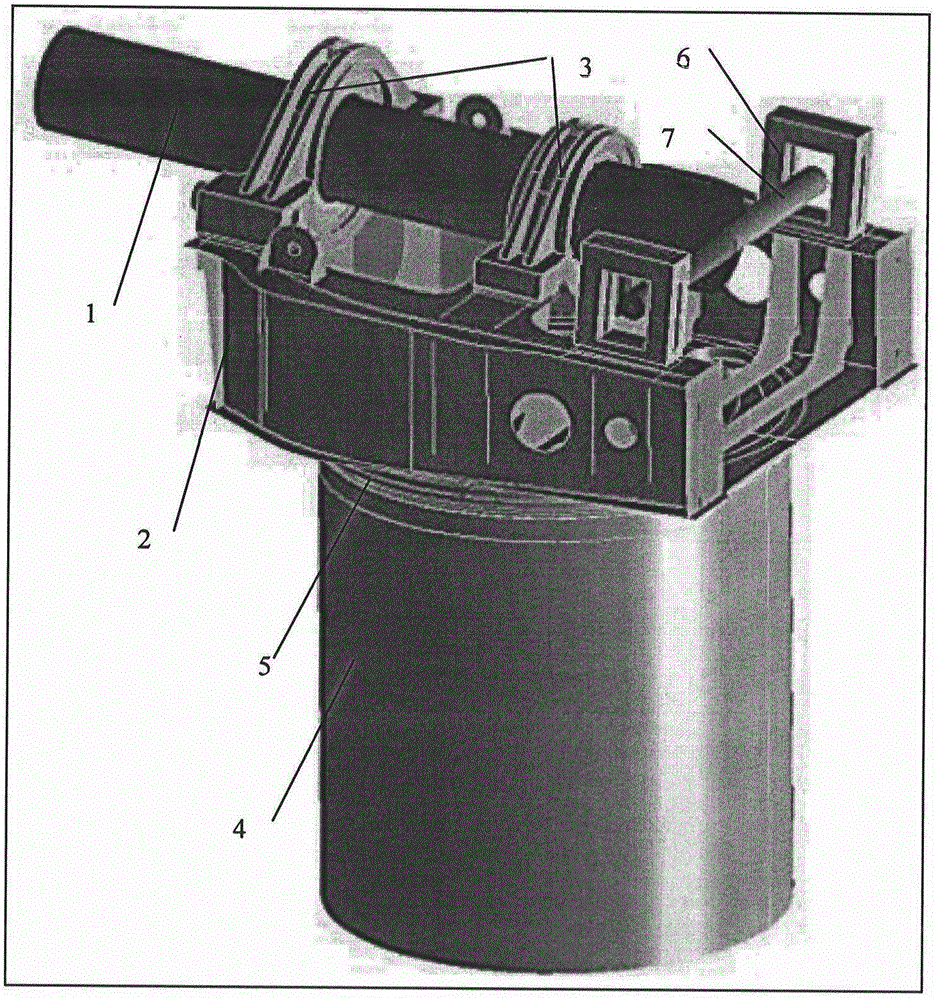

[0019] Such as figure 1 As shown, the method for calculating the strength of the main frame of the wind power generating set according to the present invention mainly includes:

[0020] (1) Using the existing finite element software as a platform, implement modeling, taking into account the main shaft 1, main bearing 3, gearbox 7, main frame 2, eccentric bearing 5 and tower 6;

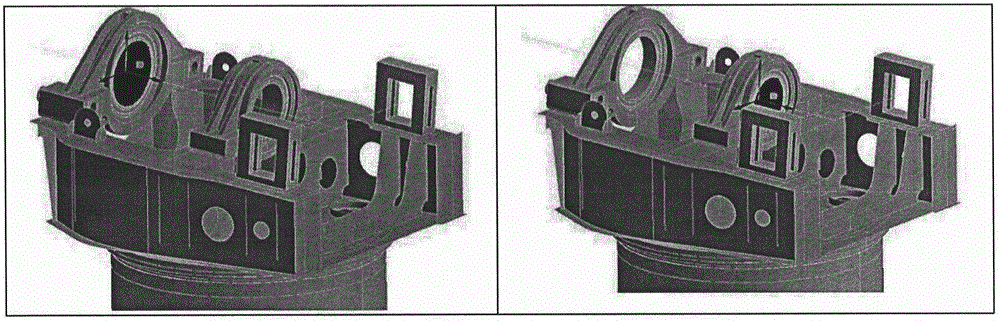

[0021] (2) Secondly, the main shaft 1 and the gearbox 7 are simulated by beam elements; the main bearing 3 and the main shaft 1 are connected by MPC, and the gearbox 7 and the support 6 are also connected by MPC, as image 3 shown;

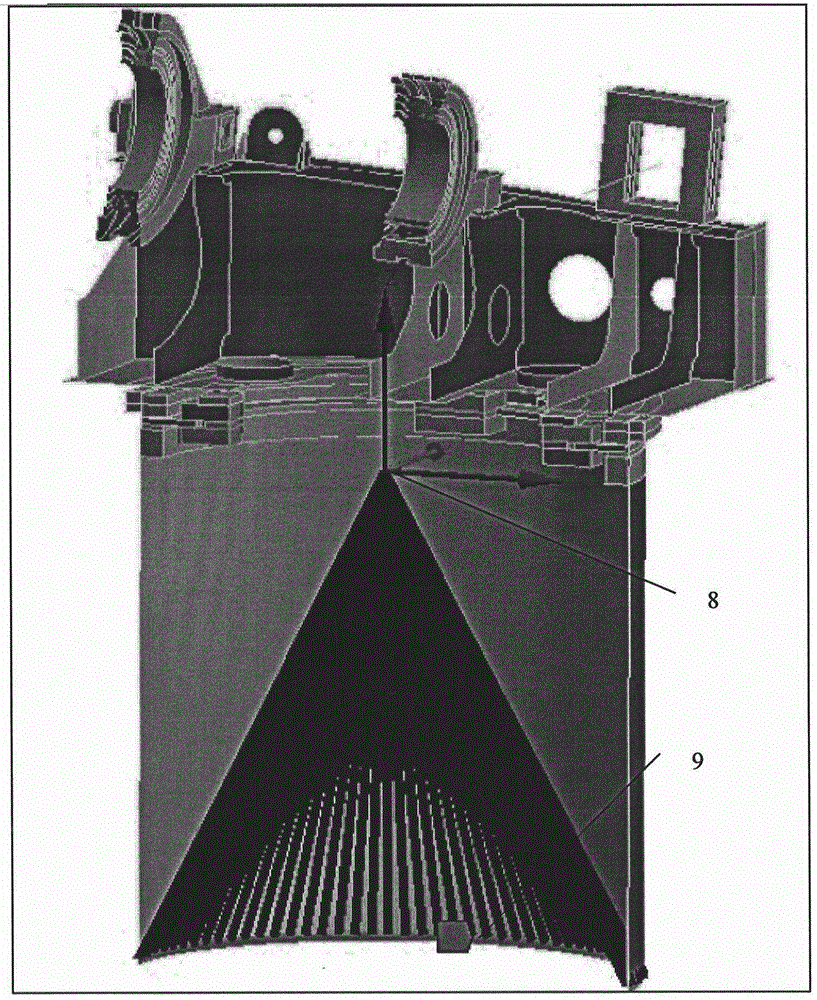

[0022] (3) Consider the main frame 2, the main bearing 3 and the gearbox support 6 as a whole. The main frame 2 adopts the shell unit; the main bearing 3, the gearbox support 6, the yaw bearing 5 and the tower 6 adopt the solid unit;

[0023] (4) Finally, define the material properties of each component, perform calculations, and obtain deformation and stress cloud diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com