Structure of drill rod for calcium carbide furnace discharge conveyer

A kind of technology of furnace and calcium carbide furnace, applied in furnace, furnace components, charge control and other directions, can solve the problems of furnace lining burning loss, increased power consumption, running eye, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

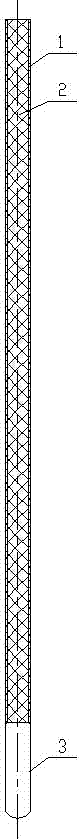

[0010] see figure 1 , a structure of the drilling rod for a calcium carbide furnace tapping machine according to the present invention, which mainly includes a clamping head 3, a hollow steel pipe 1 and a filler 2 in the hollow steel pipe, and the clamping head 3 is a mechanically operated clamp Holding the handle, the hollow steel pipe 1 is connected to the clamping head 3, and the filling material 2 is filled and solidified in the entire hollow steel pipe.

Embodiment 2

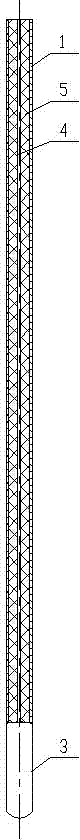

[0012] see figure 2 , the present invention relates to a drill rod structure for a calcium carbide furnace tapping machine. The drill rod with a core rod structure comprises a clamping head 3, a hollow steel pipe 1, a core rod 4, and a hollow steel pipe 1 and a core rod 4. Filling material between 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com