Continuous track self-propelled type air-conveying high-range spraying machine

A self-propelled, high-range technology, which is applied in the fields of trapping or killing insects, applications, animal husbandry, etc., can solve the problems of limited working space, waste of resources, environmental pollution, etc., and achieve spray distance and range improvement, comprehensive Improved performance and better overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

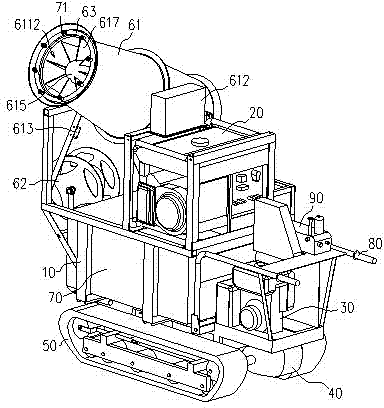

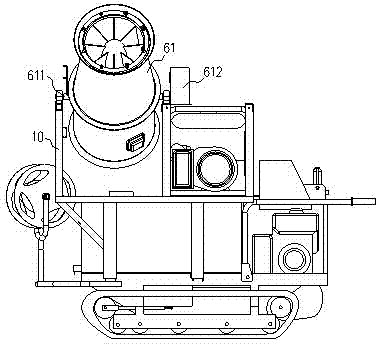

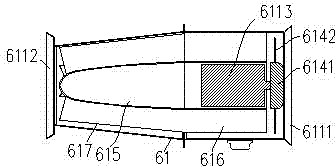

[0033] Examples, see figure 1 and figure 2 As shown, the crawler self-propelled wind-supplied high-range sprayer includes a vehicle frame 10 usually welded by steel materials. The vehicle frame 10 is provided with a generator set 20, an engine 30, a gearbox 40 connected to the engine 30, a crawler belt 50 connected to the gearbox 40 and positioned at the bottom of the frame 10, and a rotatable wind guide tube 61. , a medicine box 70 , a spray head 71 fixed on the opening of the air guide tube 61 , and the spray head 71 is connected to the medicine box 70 through a water pipe (not shown in the figure). Usually, the mouth of the air guide tube 61 is provided with a nozzle holder 63 , and the nozzle 71 is fixed on the nozzle holder 63 . Moreover, the vehicle frame 10 is also provided with a handrail 80 .

[0034] Further speaking, the medicine box 70 is located at the middle front side of the vehicle frame 10 , the engine 30 and the gearbox 40 are located at the middle re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com