A grooved filter with harm-reducing functional materials positioned in cellulose paper and its preparation method and application

A technology of cellulose paper and functional materials, applied in the directions of non-fiber pulp addition, fiber raw material treatment, application, etc., can solve the problem of insignificant reduction effect, and achieve the effect of excellent harm reduction function and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

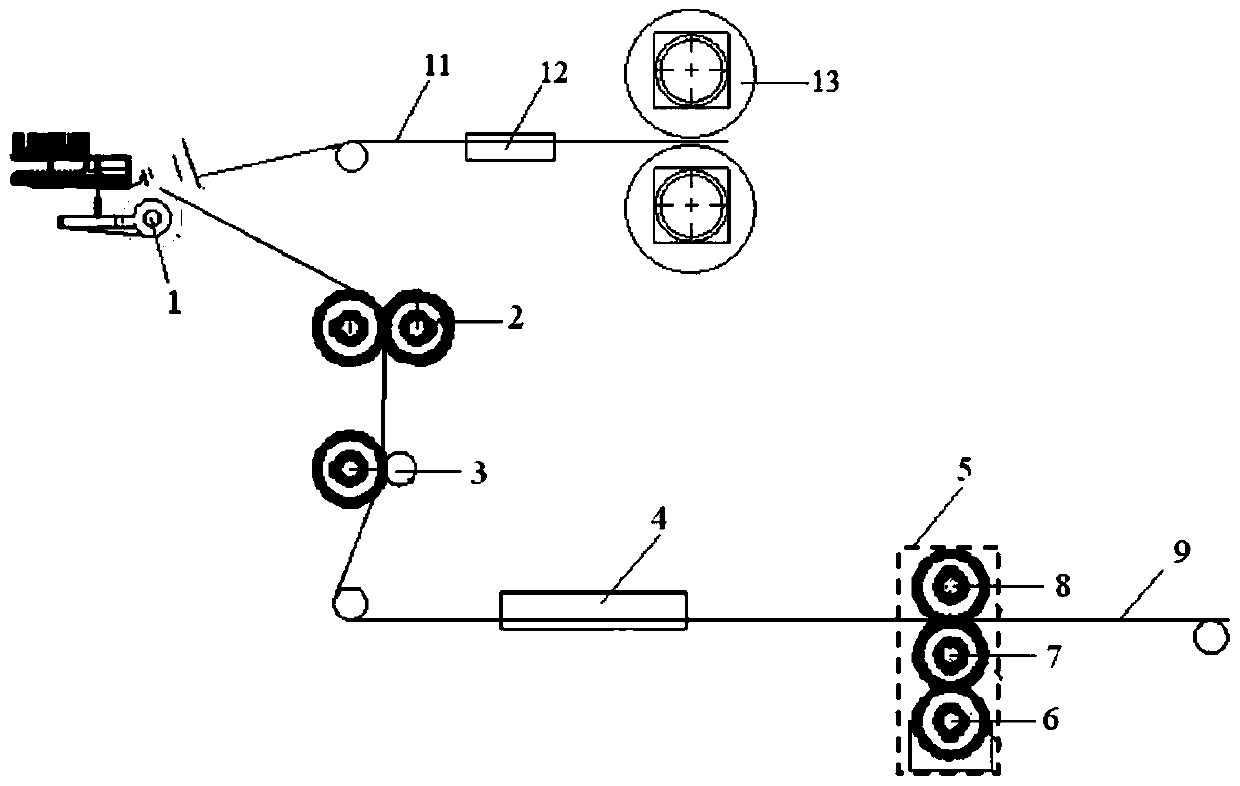

Method used

Image

Examples

Embodiment 1

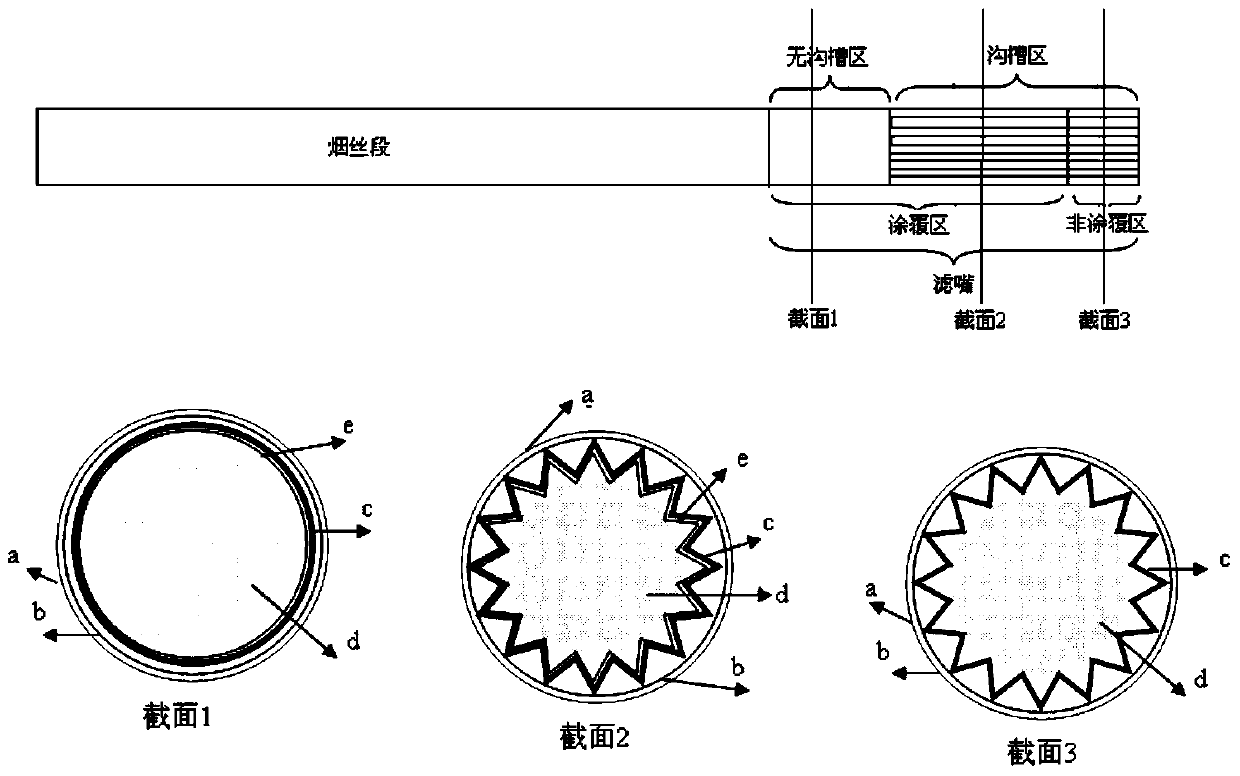

[0033] Propyl gallate, water and propylene glycol were mixed in a mass ratio of 15:35:50 to prepare a mixed solution, which was injected into the cellulose paper gluing system in the filter rod forming machine through a pump, and the forming speed of the filter rod of the forming machine was 120m / min, the temperature of the heating and drying system is 250°C. After the cellulose paper is drawn out from the coil paper, it enters the cellulose paper gluing system for on-line positioning coating of the mixed solution, and after drying, it is rolled into a functional cellulose paper groove filter. Then the cigarettes are rolled and spliced on the cigarette splicing machine, and the equipment operates normally. The ratio of the length of the area coated with functional material to the area not coated with functional material on the cellulose paper in the cigarette filter is 20:8, and the coating amount of functional material is 4mg / grooved filter. The rolled cigarettes were ana...

Embodiment 2

[0035] Tripolyglycerol monostearate and ethanol are formulated into a mixed solution in a mass ratio of 50:50, and injected into the cellulose paper gluing system in the filter rod forming machine through a pump, and the forming speed of the filter rod of the forming machine is 100m / min, the temperature of the heating and drying system is 100°C. After the cellulose paper is drawn out from the coil paper, it enters the cellulose paper gluing system for on-line positioning coating of the mixed solution, and after drying, it is rolled into a functional cellulose paper groove filter. Then the cigarettes are rolled and spliced on the cigarette splicing machine, and the equipment operates normally. The length ratio of the area coated with functional material and the area not coated with functional material on the cellulose paper in the cigarette filter is 23:5, and the coating amount of functional material is 3 mg / grooved filter. The rolled cigarettes were analyzed for smoke and...

Embodiment 3

[0037] Propyl gallate, diacetyl tartaric acid mono-diglycerides and ethanol are formulated into a mixed solution at a mass ratio of 10:20:70, and injected into the cellulose paper gluing system of the filter rod forming machine through a pump, and the filter rod of the forming machine is The molding speed is 100m / min, and the temperature of the heating and drying system is 100°C. After the cellulose paper is drawn out from the coil paper, it enters the cellulose paper gluing system for on-line positioning coating of the mixed solution, and after drying, it is rolled into a functional cellulose paper groove filter. Then the cigarettes are rolled and spliced on the cigarette splicing machine, and the equipment operates normally. The length ratio of the area coated with functional material and the area not coated with functional material on the cellulose paper in the cigarette filter is 23:5, and the coating amount of functional material is 5 mg / grooved filter. The rolled ciga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com