Application of harm-reduction function material in preparing cigarette function filter tip

A functional material and functional technology, applied in applications, e-liquid filter elements, tobacco, etc., can solve problems such as raw material loss, impact on cigarette combustion performance and combustion state, negative impact on smoke quality, etc., to achieve long process and excellent quality The effect of the harm reduction function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

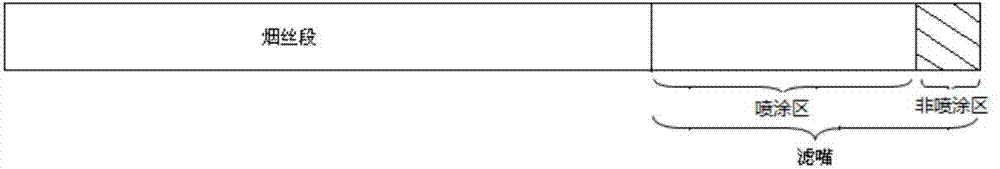

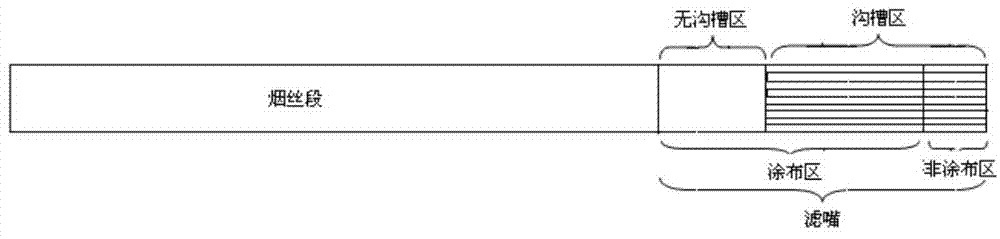

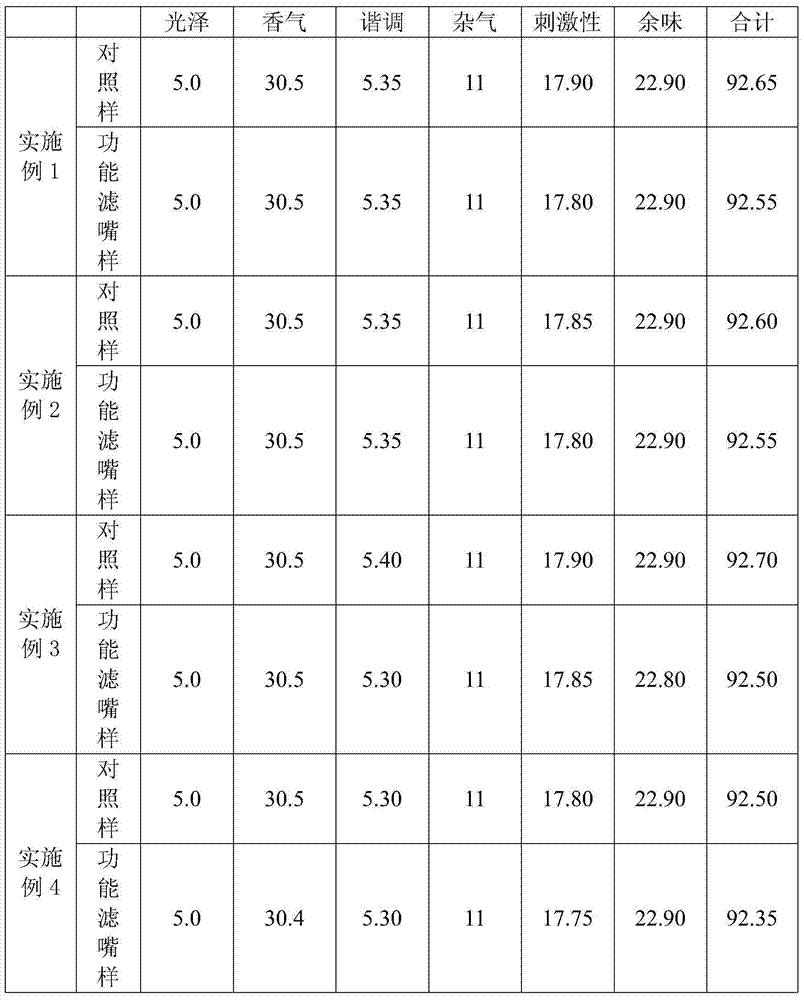

Embodiment 1

[0020] Propyl gallate, water and propylene glycol are prepared into a mixed solution at a mass ratio of 15:35:50, coated on cellulose paper during the molding process of the groove filter, and dried, and the prepared cigarette functional cellulose paper groove filter The area coated with the functional material on the cellulose paper in the mouth is close to the end of the shredded tobacco, and the length ratio of the area coated with the functional material to the area not coated with the functional material is 20:8; the coating amount of the functional material is 4mg / cigarette functional fiber Plain paper groove filter. Cigarettes rolled with functional grooved filters were analyzed for smoke and harmful components. Compared with the control sample of ordinary acetate grooved filters, the amount of tar released in smoke was reduced by 2.35%, and the harmful component of smoke, crotonaldehyde, was significantly reduced by 35.6%. , reducing the harmful components of smoke HCN...

Embodiment 2

[0022] Triglycerol monostearate and ethanol are formulated into a mixed solution at a mass ratio of 50:50, coated on cellulose paper during the groove filter forming process, and dried to prepare cigarette functional cellulose paper grooves The area coated with functional material on the cellulose paper in the filter is close to the tobacco end, and the length ratio of the area coated with functional material to the area not coated with functional material is 23:5; the coating amount of functional material is 3mg / cigarette functional fiber Plain paper groove filter. Cigarettes rolled with functional grooved filters were analyzed for smoke and harmful components. Compared with the control sample of ordinary acetate grooved filters, the amount of tar released in smoke was reduced by 1.25%, and the harmful component of smoke, crotonaldehyde, was significantly reduced by 37.2%. , reducing the harmful components of smoke HCN50.4%, significantly reducing the harmful components of sm...

Embodiment 3

[0024]Propyl gallate, diacetyl tartrate mono-diglyceride, and ethanol are prepared as a mixed solution at a mass ratio of 10:20:70, coated on cellulose paper during the molding process of the grooved filter, and dried to prepare cigarettes with functional properties In the cellulose paper groove filter, the area coated with the functional material on the cellulose paper is close to the tobacco end, and the length ratio of the area coated with the functional material to the area not coated with the functional material is 23:5; the coating amount of the functional material is 5mg Each cigarette features a cellulose paper grooved filter. Cigarettes made with functional grooved filters were analyzed for smoke and harmful components. Compared with the control sample of ordinary cellulose acetate grooved filters, the amount of tar released in smoke was reduced by 6.85%, and the harmful component of smoke, crotonaldehyde, was significantly reduced by 41.0%. , reducing the harmful com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com