sheet metal cutting device

A technology for cutting devices and metal plates, which is applied in metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve problems such as time-consuming and cost-consuming, unsatisfactory shape of metal plates, poor shape and structure of final products, etc., to achieve Improved cut surface quality, cost and time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

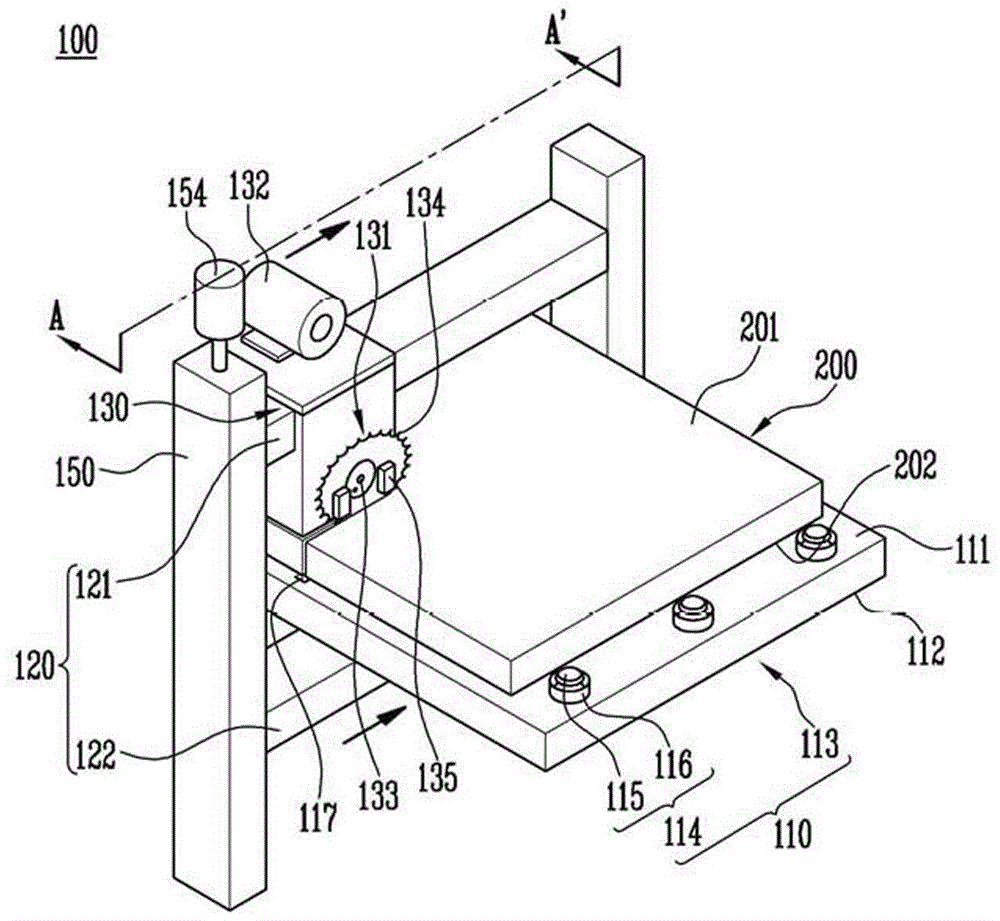

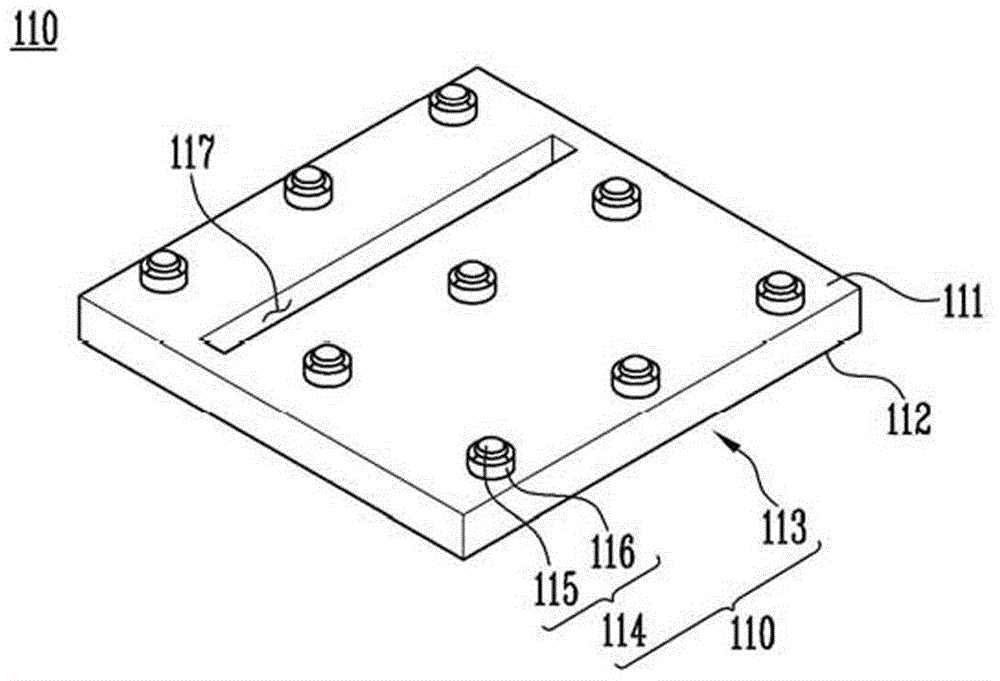

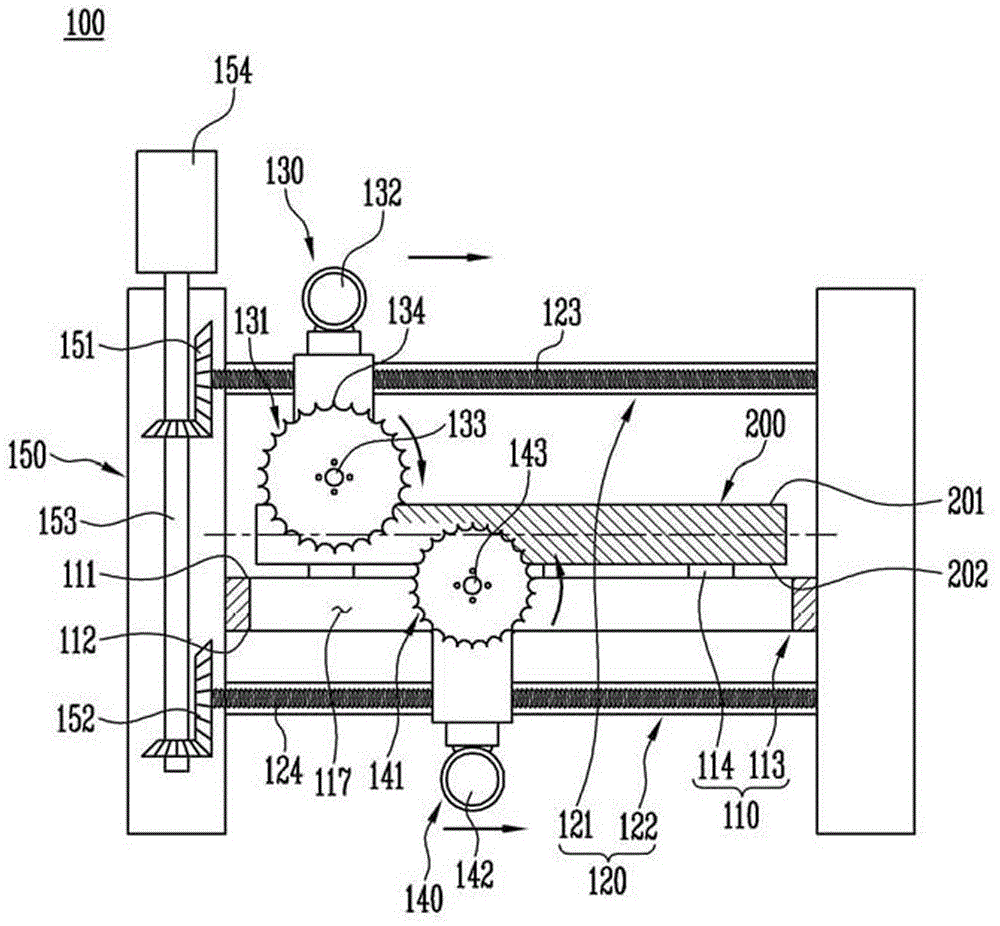

[0039] The purpose, specific advantages and novel features of the present invention will become more apparent through the following description and examples in connection with the accompanying drawings. Note that, in this specification, when assigning reference numerals to constituent elements in the respective drawings, if the same constituent elements are shown in different drawings, the same numerals are assigned as much as possible. Moreover, in the process of describing the present invention, if it is considered that the specific description of related known technologies may cause unnecessary confusion to the gist of the present invention, the detailed description will be omitted.

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0041] figure 1 It is a schematic perspective view of the sheet metal cutting device 100 according to the embodiment of the present invention. Hereinafter, the metal plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com