Method for precracking of thick hard difficult-to-break coal mine top board by supercritical CO2

A supercritical, coal mine technology, applied in ground mining, earthwork drilling, underground mining, etc., to avoid dynamic disasters, reduce the area of overhanging roofs, and ensure safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

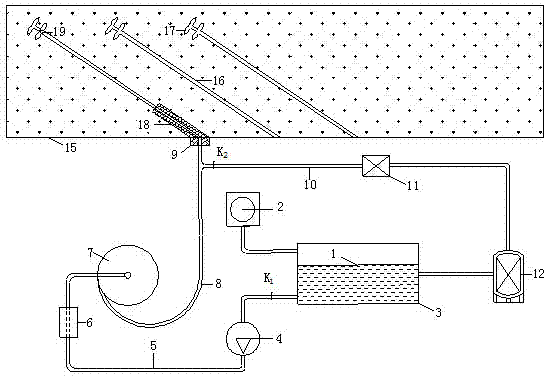

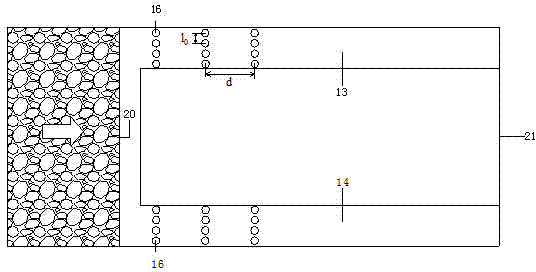

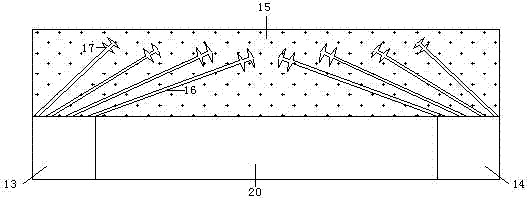

Method used

Image

Examples

Embodiment Construction

[0039] The following examples are intended to illustrate and explain the present invention, but not to limit the scope of the present invention.

[0040] In order to have a clearer understanding of the technical objectives, features and effects of the present invention, the supercritical CO2 The pre-splitting fine-grained sandstone roof with a thickness of 10.1m, Platinum hardness f=8-9, dense distribution and good integrity in a mine of Lu'an Group will be further explained in detail.

[0041] The No. 3 coal seam in a mine of Lu'an Group is stable, with an average thickness of 5.6m, a dip angle of 3.5°, a buried depth of 506.15m, a strike length of 1536m, and a dip length of 240m. At present, the No. 3 coal seam adopts the longwall retreating fully mechanized caving mining method. The immediate roof of the No. 3 coal seam is gray-black argillaceous sandstone with a thickness of 2.56m and a Platinum hardness of f=3-4, and relatively well-developed vertical fissures; the basic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole spacing | aaaaa | aaaaa |

| Critical temperature | aaaaa | aaaaa |

| Critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com