A filter system for slurry bed reactor

A filter system and reactor technology, applied in the direction of filtration separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of filter cake falling off, affecting the effect of backwash regeneration, etc., achieve complete backwash and increase service life And the effect of use and the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

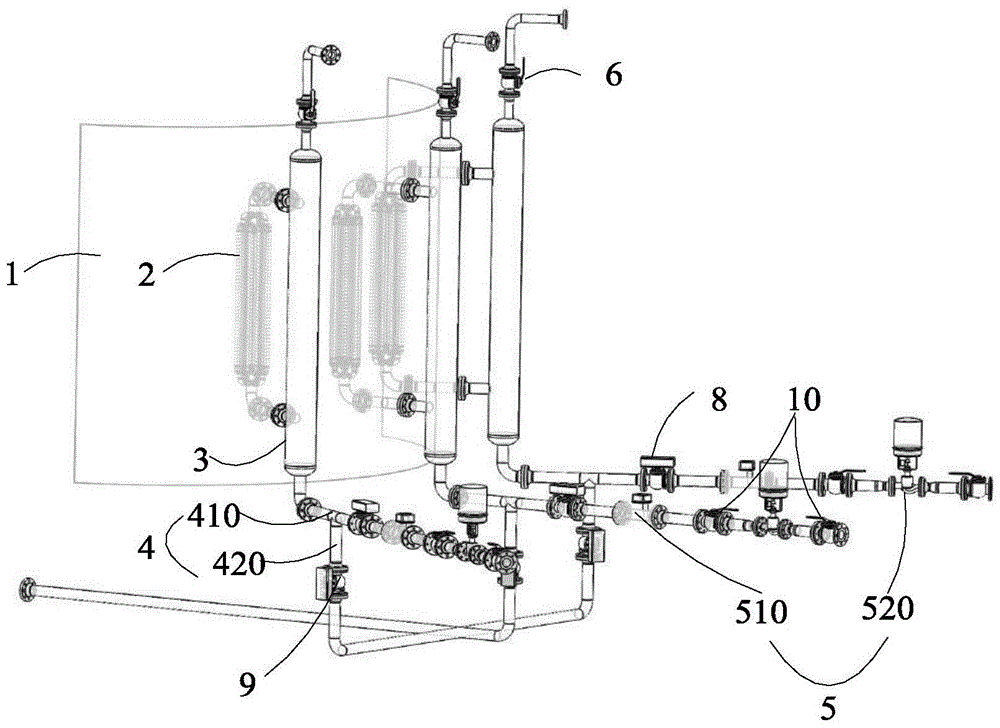

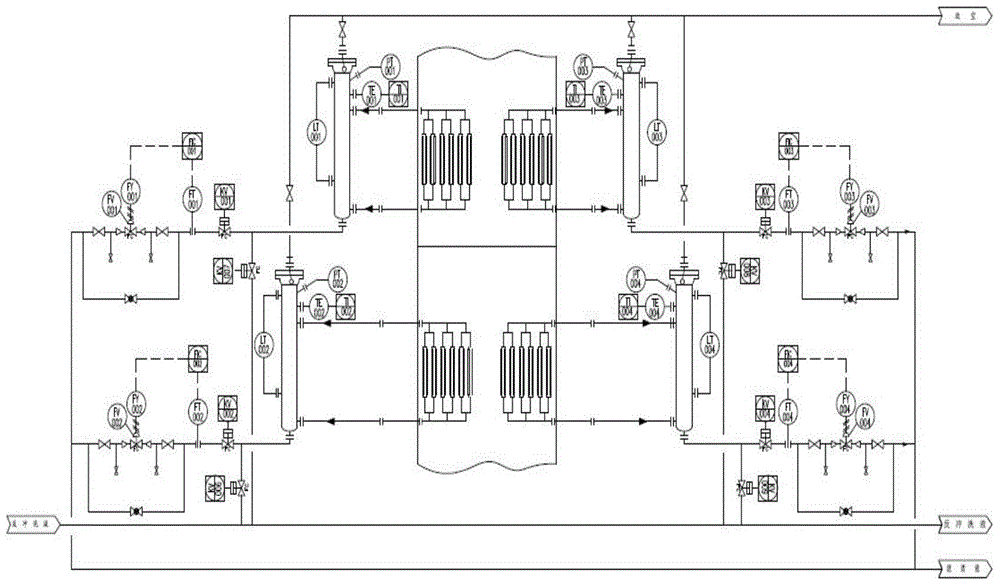

[0043] figure 1 and figure 2 A filtration system for a slurry bed reactor according to the present invention is shown, comprising:

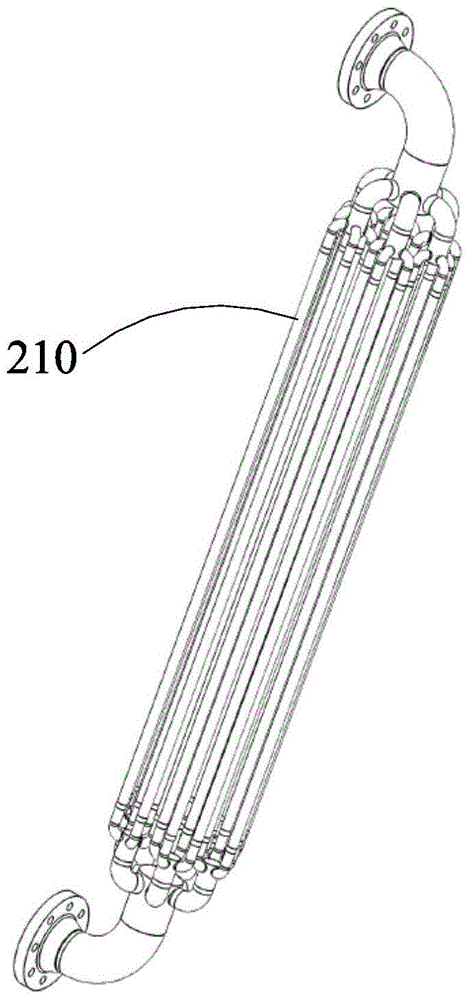

[0044] at least one set of filtering means comprising:

[0045] One set of filter assemblies 2, which are vertically arranged in the slurry bed reactor 1;

[0046] A manifold 3, which is arranged on the outside of the slurry bed reactor 1, said manifold 3 is a pipeline with a gas-liquid separation device at the upper end and an opening at the lower end, said manifold 3 is connected to the upper end of a group of filter assemblies 2 and The lower end is communicated with the side wall of the slurry bed reactor 1, the upper and lower ends of the filter assembly 2 are connected to the manifold, the filtrate can flow out from the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com