Non-metal armoring enhancement type self-supporting optical fiber cable

A self-supporting fiber optic cable, enhanced technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of reduced fear, the weight of the fiber optic cable itself, and the gnawing of the fiber optic cable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

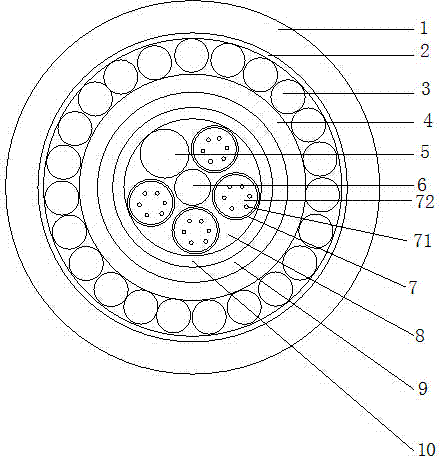

[0018] like figure 1 As shown, the non-metallic armored reinforced self-supporting optical cable of the present invention includes a central strength member 6, a loose tube 7, a polyester tape 2, a glass fiber reinforced plastic layer 3 and an outer sheath 1, and the central strength member A number of loose tubes 7 are twisted around 6, and each loose tube 7 is equipped with a single-core or multi-core optical fiber 71 and filled with fiber paste 72. The polyester tape 2 is longitudinally wrapped in the outer sheath 1, and the polyester tape 2 A glass fiber reinforced plastic layer 3 is stranded, and a middle protective layer 4 and an inner cushion layer 10 are arranged inside the glass fiber reinforced plastic layer 3, and an aramid fiber 9 is arranged between the middle protective layer 4 and the inner cushion layer 10, and the inner cushion layer 10 Cable paste 8 is filled between each loose tube 7 inside, and the loose tube 7 and a filling rope 5 are twisted around the ce...

Embodiment 2

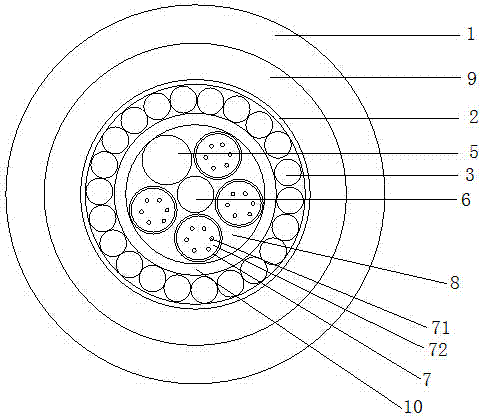

[0020] like figure 2 As shown, the non-metallic armored reinforced self-supporting optical cable of the present invention includes a central strength member 6, a loose tube 7, a polyester tape 2, a glass fiber reinforced plastic layer 3 and an outer sheath 1, and the central strength member A number of loose tubes 7 are twisted around 6, and each loose tube 7 is equipped with a single-core or multi-core optical fiber 71 and filled with fiber paste 72. The polyester tape 2 is longitudinally wrapped in the outer sheath 1, and the polyester tape 2 A glass fiber reinforced plastic layer 3 is stranded, an aramid fiber 9 is arranged between the outer sheath 1 and the polyester tape 2, an inner cushion layer 10 is arranged inside the glass fiber reinforced plastic layer 3, and each loose sleeve in the inner cushion layer 10 Cable paste 8 is filled between the tubes 7 , and the loose tube 7 and a filling rope 5 are twisted around the central reinforcement 6 .

Embodiment 3

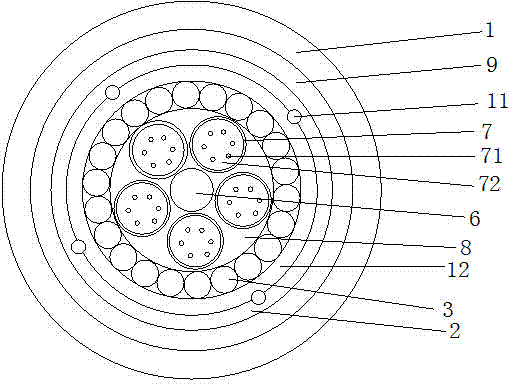

[0022] like image 3 As shown, the non-metallic armored reinforced self-supporting optical cable of the present invention includes a central strength member 6, a loose tube 7, a polyester tape 2, a glass fiber reinforced plastic layer 3 and an outer sheath 1, and the central strength member A number of loose tubes 7 are twisted around 6, and each loose tube 7 is equipped with a single-core or multi-core optical fiber 71 and filled with fiber paste 72. The polyester tape 2 is longitudinally wrapped in the outer sheath 1, and the polyester tape 2 A glass fiber reinforced plastic layer 3 is stranded, an aramid fiber 9 is arranged between the outer sheath 1 and the polyester tape 2, a glass fiber braided tape 12 is arranged between the polyester tape 2 and the glass fiber reinforced plastic layer 3, and the glass fiber The cable paste 8 is filled between the loose tubes 7 in the reinforced plastic layer 3 , and the water-blocking yarn 11 is spirally wound between the polyester tap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap