Combustion control device and method for a gas turbine

A gas turbine and control device technology, which is applied in the direction of fuel control, charging system and engine components of turbine/propulsion device, can solve the problems of high cost, low precision, and inconvenient operation, so as to prevent abnormal flameout and improve control accuracy , the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

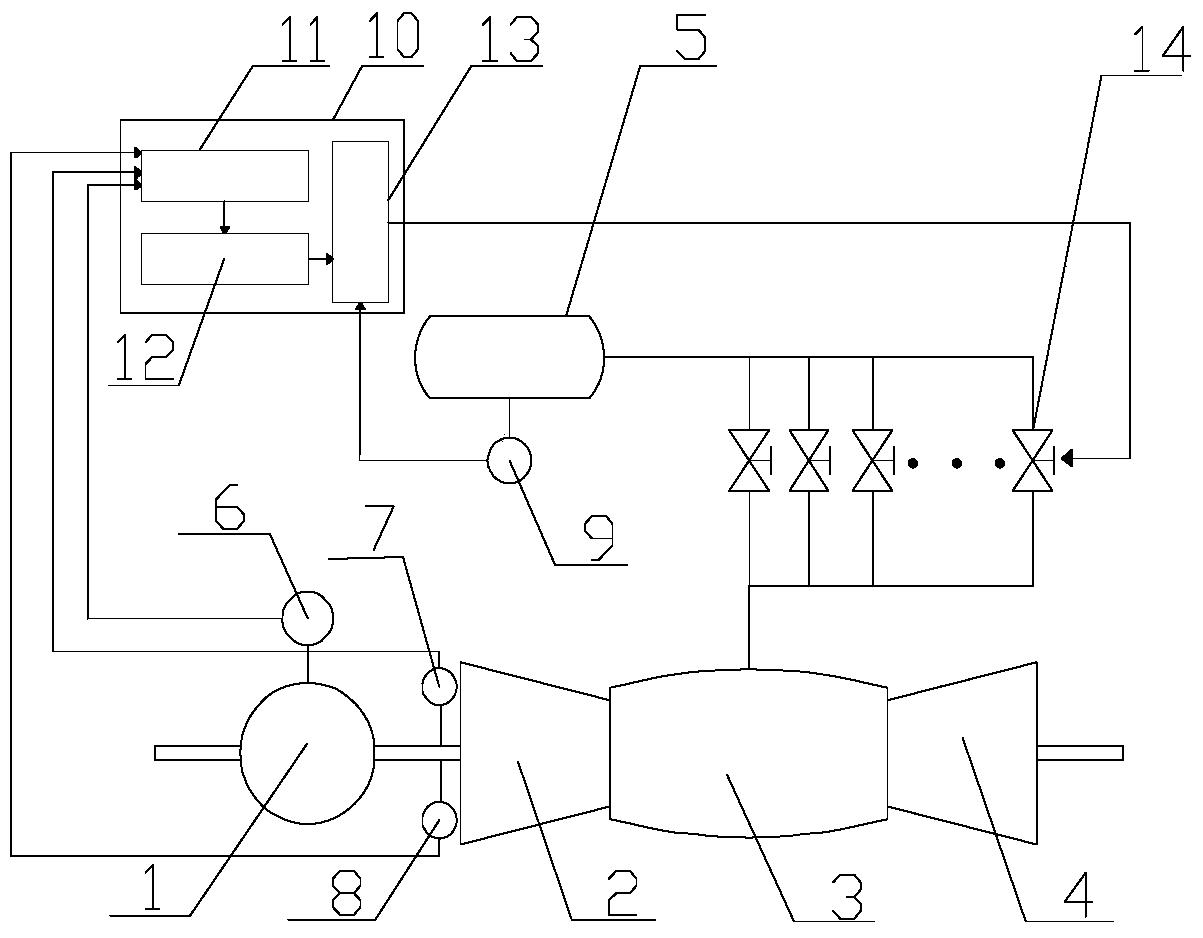

[0044] Such as figure 1 As shown, a gas turbine combustion control device provided by the embodiment of the present invention, the gas turbine includes a generator 1, a compressor 2, a multi-nozzle combustion chamber 3 and a turbine 4, and the control device includes a control module 10, a measuring device and a valve group, The measuring device includes a load sensor 6 arranged on the generator 1, a fuel temperature sensor 9 arranged on the gas fuel tank 5, and a temperature sensor 7 and a pressure sensor 8 arranged at the inlet of the compressor 2; the valve group includes at least two The parallel control valves 14 include five control valves 14 in this embodiment, the gas fuel tank 5 communicates with the combustion chamber 3 through the valve group, and the gas fuel tank 5 communicates with the valve group through a shut-off valve.

[0045] The quantity of load sensor 6, fuel temperature measuring sensor 9, temperature sensor 7 and pressure sensor 8 is one or more, and 2 ...

Embodiment 2

[0049] This embodiment provides a control method for a gas turbine combustion control device, including the following steps:

[0050] S1, the load value of the generator 4, the temperature value and the pressure value of the compressor 5 inlet measured by the load sensor 6, the temperature sensor 7 and the pressure sensor 8, and the conversion load value is calculated, and the calculation formula of the conversion load value is:

[0051]

[0052] Among them, PW is the generator load value, T0 is the temperature value of the compressor inlet, P0 is the pressure value of the compressor inlet, PW r is the converted load value;

[0053] The load value of the generator 4 is the maximum value of the motor load measurement value measured by one or more load sensors, and the temperature value and pressure value of the inlet of the compressor 5 are the compressed gas measured by one or more temperature sensors 8 and pressure sensors 9 respectively. The middle value of the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com