Electric mop barrel integrating positive and reverse rotation washing and dewatering functions

A forward-reversing, mop bucket technology, applied in the field of sanitary ware, can solve the problems of inability to wash, reduce the efficiency of mop washing, and only one-way rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

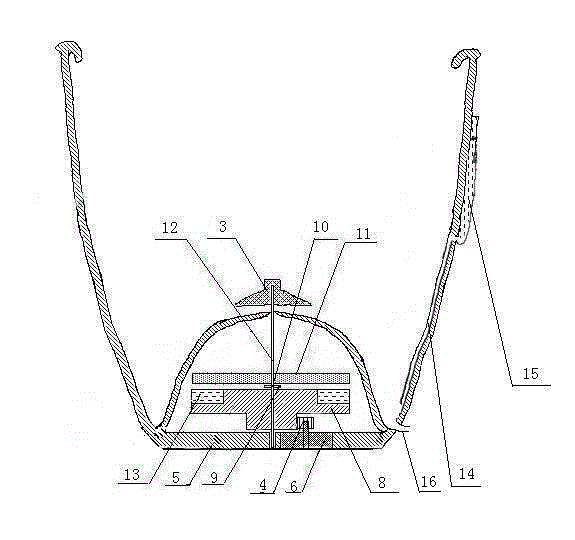

[0022] The electric forward and reverse elutriation and dehydration integrated mop bucket consists of a bucket body 1, a base 5, a handle 2, an elutriation and dewatering tray 3, a rotating shaft 12 connecting the elutriation and dehydration tray 3 and the base 5, a motor 6, The control panel 15 and the drain valve 16 are composed, and it is characterized in that: one end of the rotating shaft 12 passes through the barrel body 1 and is fixedly connected with the elutriation and dewatering tray 3, and the other end passes through the center of the drive disc 8 and the drive disc drive wheel 7 The shaft is vertically installed in the limit hole on the base 5, and the rotating shaft 12 can rotate freely; A metal gasket 9 is fixed on it; the rotating shaft 12 is fixed with an induction disc 11 between the elutriation and dewatering tray 3 and the draw-in slot 10 near the draw-in slot 10; the center of the induction disc 11 is on the rotating shaft 12, and The disk surface of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com