System and method for identification of implement motion in a power tool

A technology for electric tools and instruments, which is applied in the system field of instrument movement, can solve the problems of increasing the complexity of the saw 1 and the unreliability of the sensing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

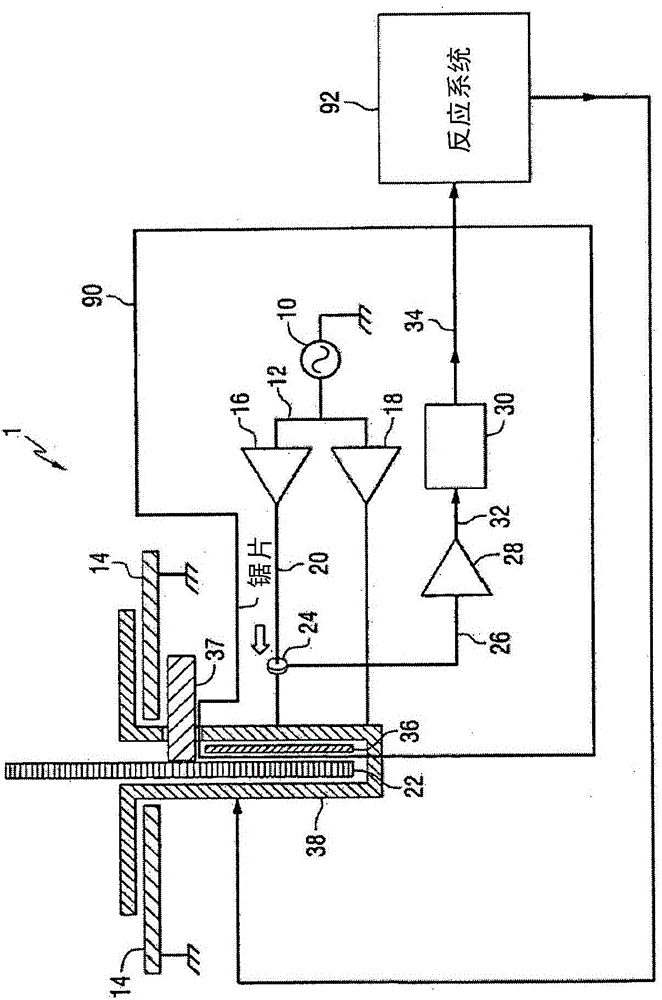

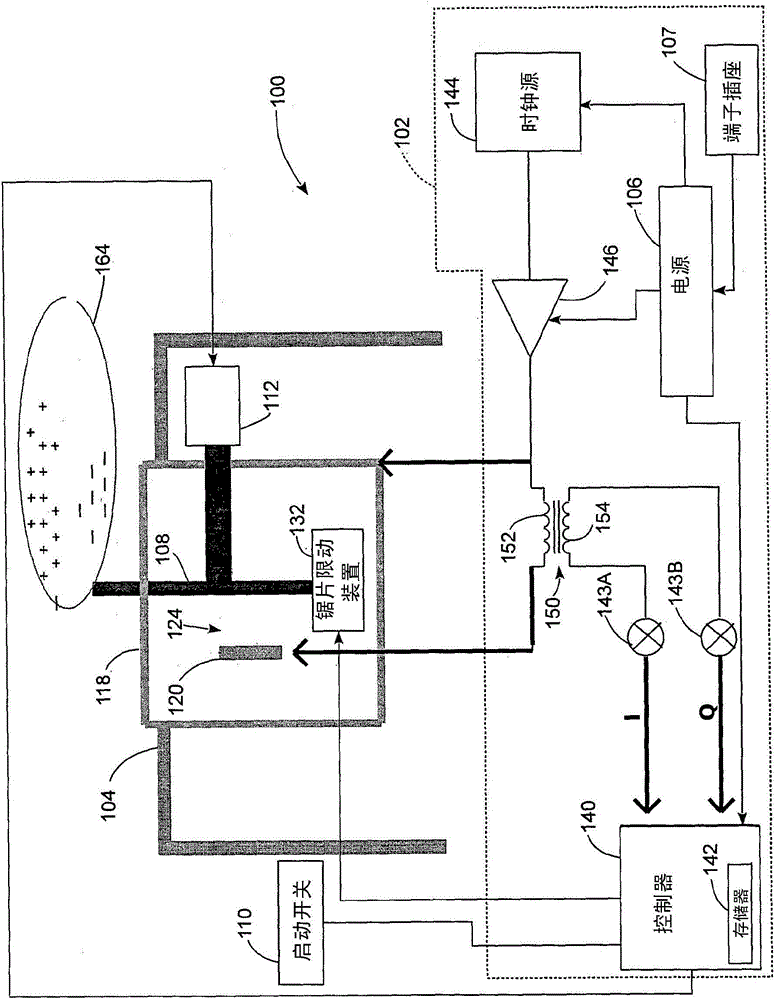

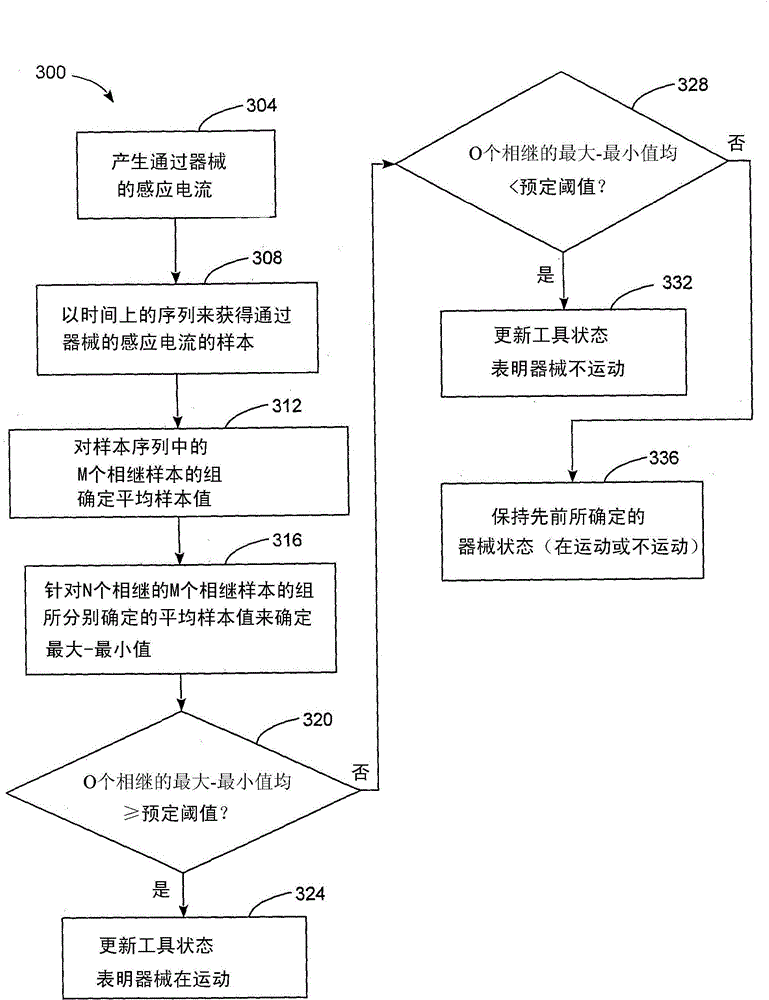

[0021] For the purpose of promoting an understanding of the principles of the embodiments described herein, reference is now made to the drawings and description in the following written specification. These references are not intended to limit the scope of the subject matter. This application also includes any changes and modifications to the illustrated embodiments and further applications of the principles of the described embodiments that would normally occur to one skilled in the art to which this document pertains.

[0022] As used herein, the term "power tool" refers to any tool having one or more moving parts moved by an actuator, such as an electric motor, internal combustion engine, hydraulic or pneumatic cylinder, and the like. Examples of power tools include, but are not limited to, miter saws, miter saws, table saws, circular saws, reciprocating saws, jigsaws, band saws, cold saws, cutters, impact drivers, angle grinders, drills, Jointers, nailers, sanders, trimm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com