Inner blowout prevention double floating valves of double-wall drill pipe

A double-wall drill pipe, double-floating technology, used in earth-moving drilling, wellbore/well valve devices, wellbore/well components, etc. blowout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

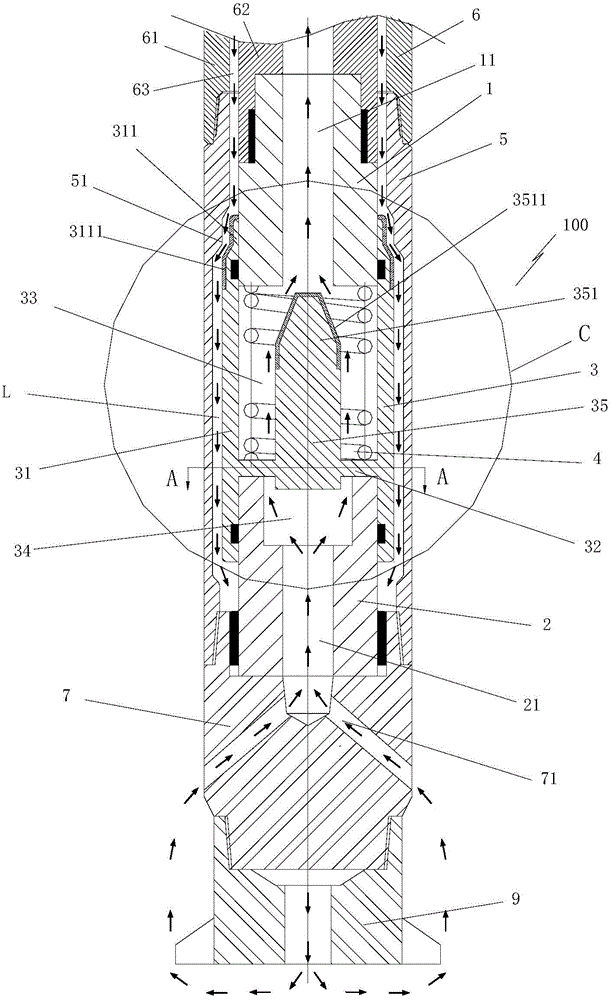

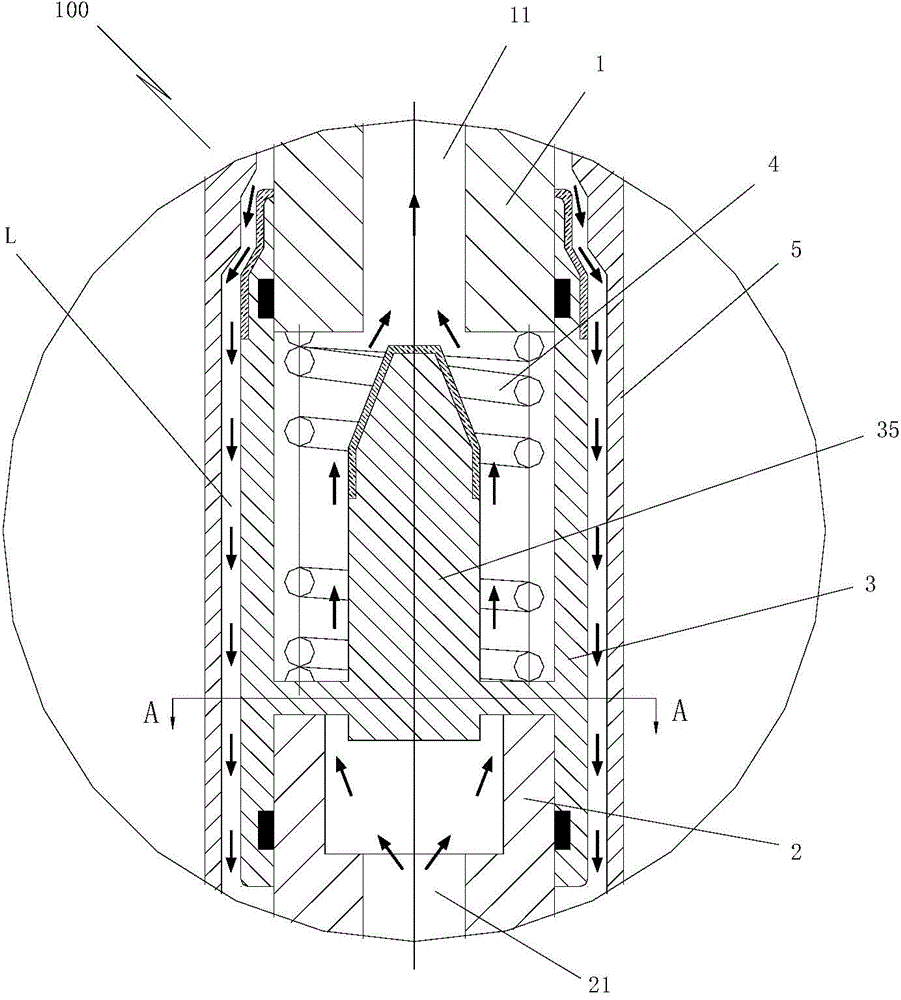

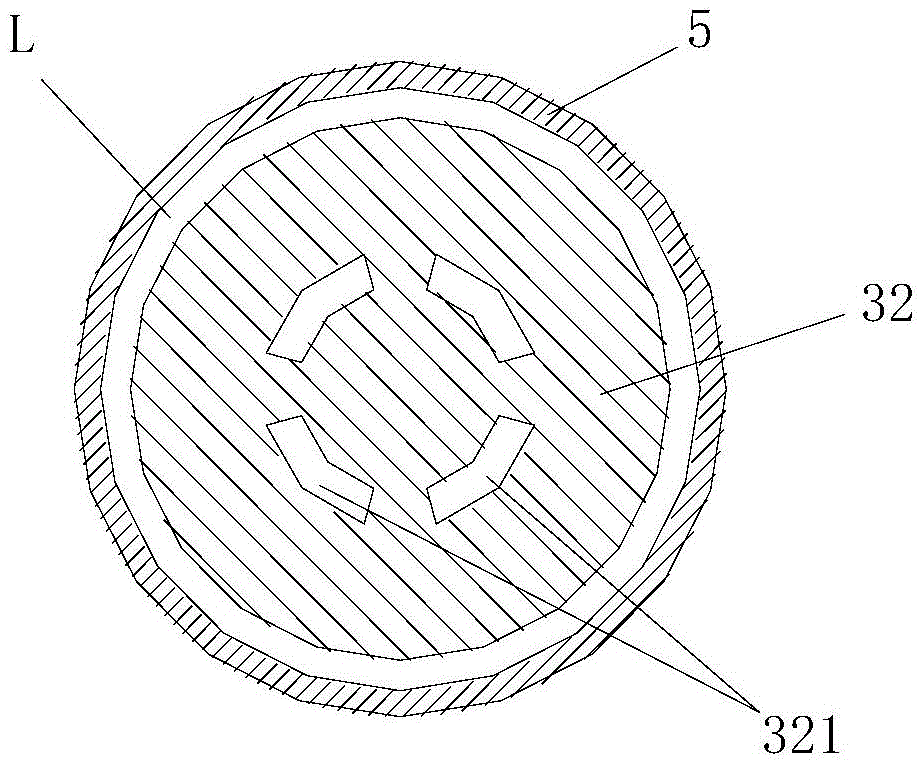

[0027] Such as figure 1 , figure 2 As shown, the present invention proposes a double-wall drill pipe internal blowout prevention double-floating valve 100. The double-floating valve 100 includes an upper valve seat 1, a lower valve seat 2, and a coaxial sliding valve between the upper and lower valve seats. The floating valve core 3; the upper and lower valve seats are cylinders, the center of the upper valve seat 1 is provided with a first axial through hole 11, and the center of the lower valve seat 2 is provided with a second axial through hole 21 (in this In the embodiment, the second axial through hole 21 may be a stepped hole with a large top and a small bottom), the floating valve core 3 includes an outer positioning sleeve 31 coaxially sealed and slidably arranged on the outer walls of the upper and lower valve seats, The outer layer positioning sleeve 31 is horizontally sealed with a partition plate 32, and the outer layer positioning sleeve 31 is divided into an up...

Embodiment 2

[0035] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that Figure 7 As shown, in this embodiment, the upper end of the double-floating valve 100 is connected to a first double-wall drill rod 6 , and the lower end of the double-float valve 100 is connected to a second double-wall drill rod 8 .

[0036] Such as Figure 7 As shown, the outer wall of the upper end of the valve sleeve 5 is threadedly connected to the inner wall of the outer tube 61 of the first double-wall drill rod 6, and the inner wall of the lower end of the valve sleeve 5 is threadedly connected to the outer wall of the outer tube 81 of the second double-wall drill rod 8. , the top end of the upper valve seat 1 is sealed and inserted in the inner tube 62 of the first double-walled drill rod, the first axial through hole 11 is connected to the inner tube 62 of the first double-walled drill rod, and the The bottom end of the lower valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com