Implementation method for rhombus composite stirring pile forming machine

A pile machine, diamond technology, applied in sheet pile wall, construction, infrastructure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

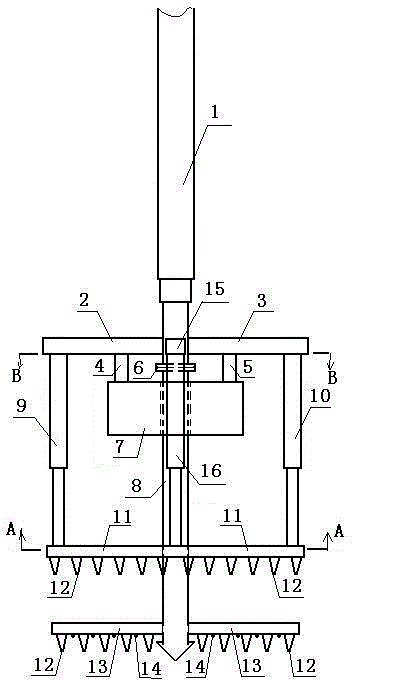

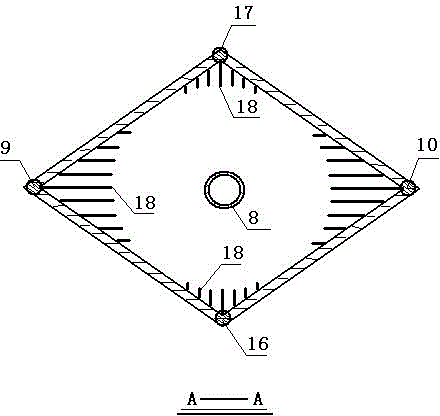

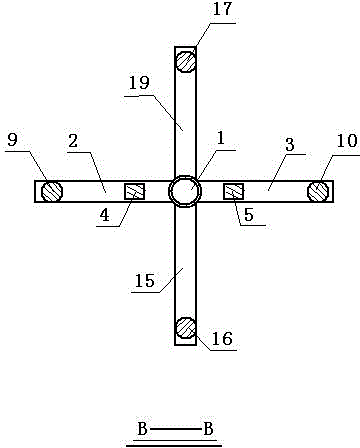

[0014] The drawing shows a specific embodiment of the present invention. In this embodiment, the lower end port of the extension pipe 1 is connected to the upper end port of the rotating pipe 8 through a sliding oil seal 6. The lower end of the rotating pipe is provided with a stirring head 13, and a plurality of first knives are arranged under the stirring head The teeth 12 are provided with a plurality of slurry outlets 14 between the cutter teeth; the first arm 2 is fixed on the left side of the lower part of the extension pipe, and the left end of the first arm is fixed to the upper end of the first hydraulic cylinder 9. The lower end is fixed to the left end of the diamond frame 11, the second arm 3 is fixed on the right side of the lower part of the extension tube, the right end of the second arm is fixed to the upper end of the second hydraulic cylinder 10, and the lower end of the second hydraulic cylinder is fixed to the diamond frame 11 At the right end, a third arm 15...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap