Dry calibrator that eliminates seam marks on profile surfaces

A dry-type shaping and profile technology, which is applied in the field of dry-type shaping molds, can solve the problems of affecting the appearance quality of foamed profiles, increasing production costs, and increasing the rate of defective products, so as to eliminate splicing marks on the foaming surface, improve strength, The effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

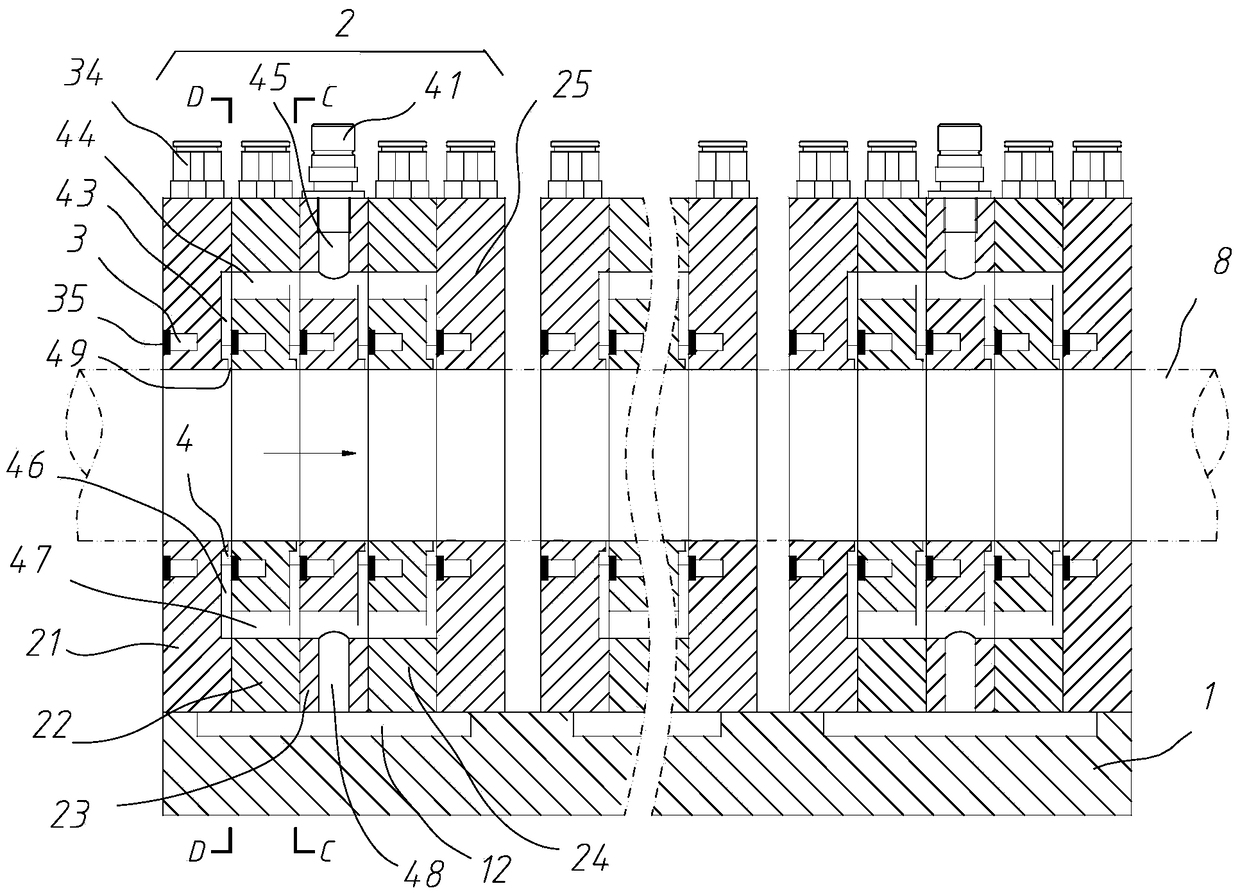

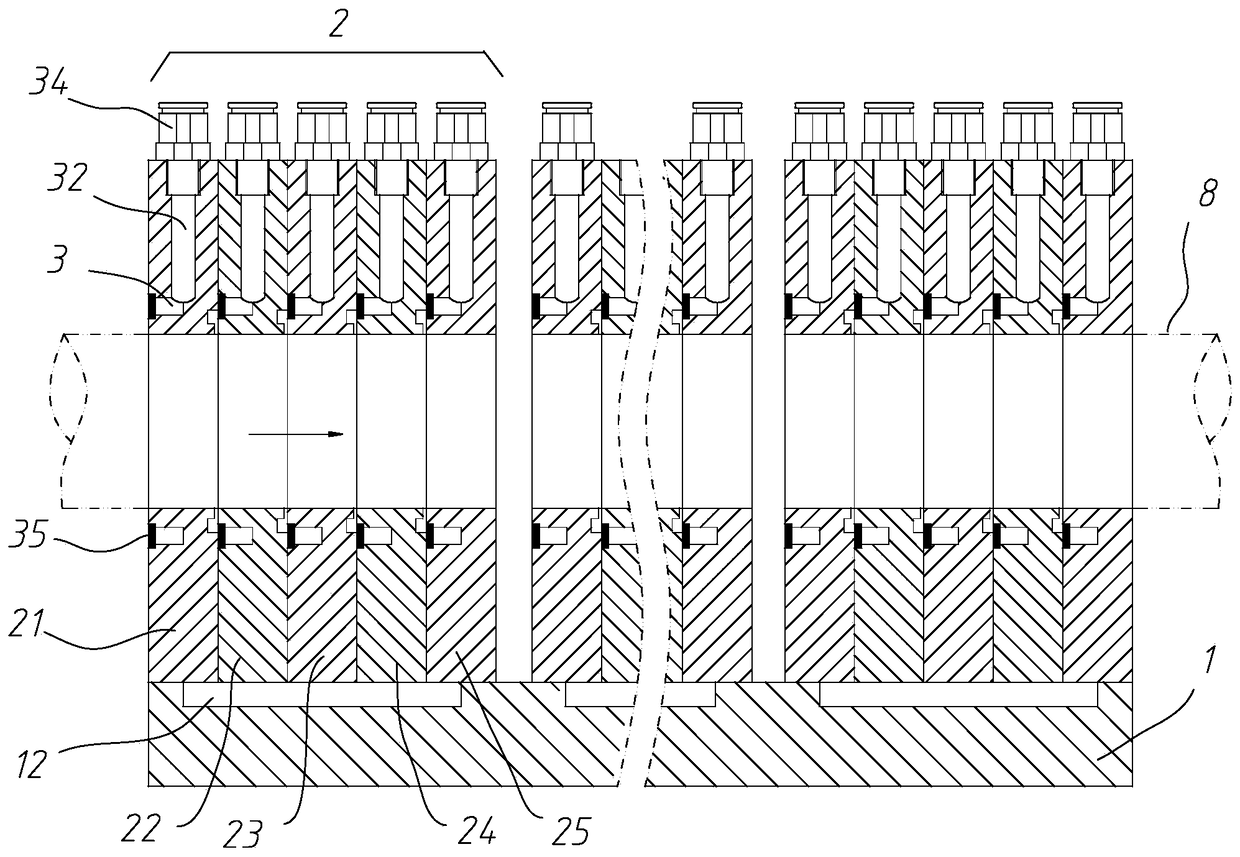

[0019] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

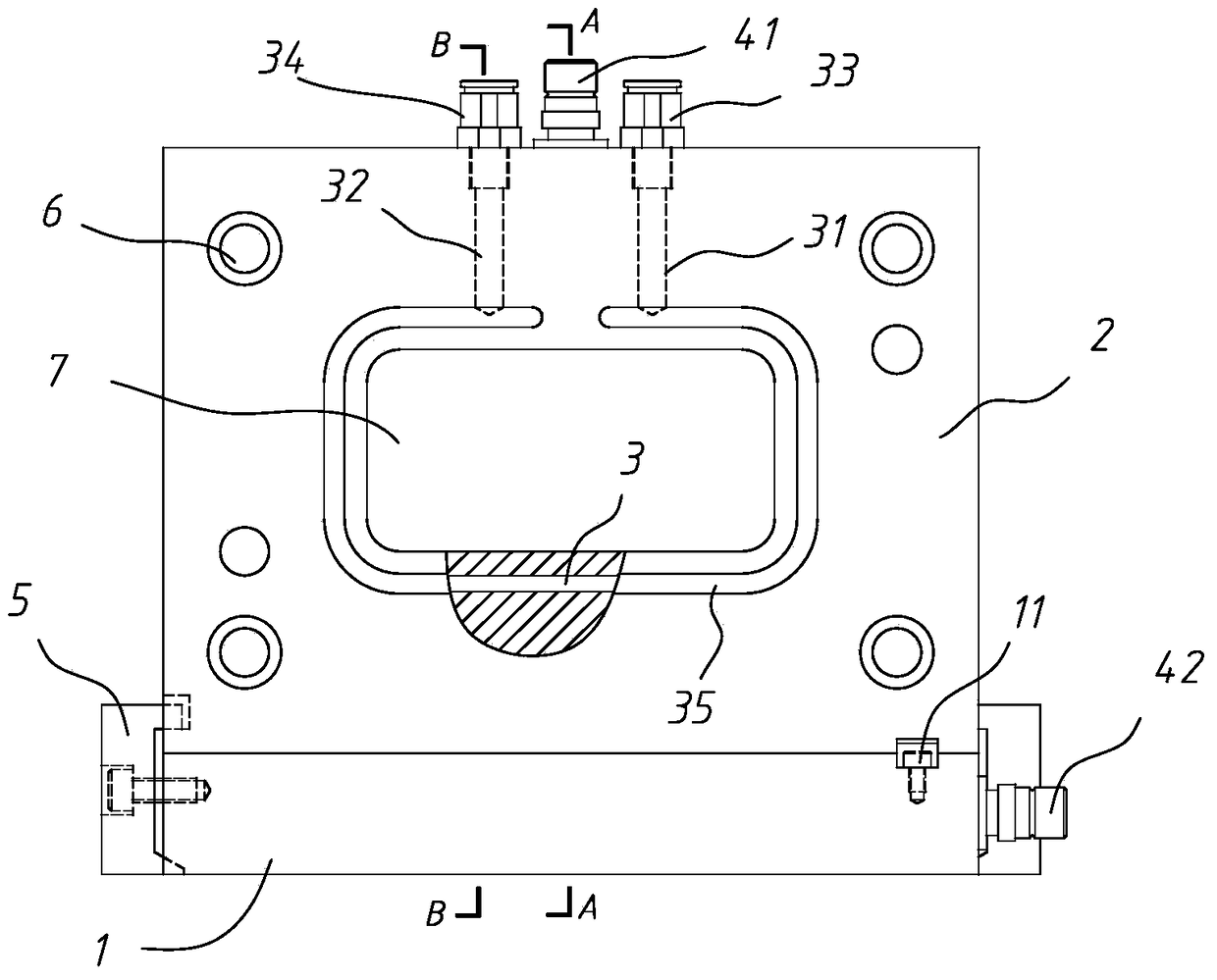

[0020] The present invention comprises a platen 1, at least one group of shaping components 2 is fixed on the platen 1, there are three to four groups of shaping components 2 in this example, and each group of shaping components 2 is independently fixed on the platen 1 sequentially along the moving direction of the parison 8 , each group of shaping components 2 is composed of five templates 21-25, and the templates 21-25 are arranged longitudinally and connected by bolts 6. In order to ensure that the cavity heights of the templates of each sizing component are consistent, blocks 5 for fixing the sizing component 2 are provided on both sides of the platen 1 , and the lower ends of each template are connected to the platen 1 through positioning square keys 11 .

[0021] A cavity 7 matching the shape of the parison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com