High-power rolling type collector ring device

A slip ring and rolling type technology, which is applied in the field of high-power rolling slip ring devices, can solve the problems of increased cost, high requirements for selection and assembly, and achieve the effects of reducing manufacturing costs, expanding the scope, and increasing the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

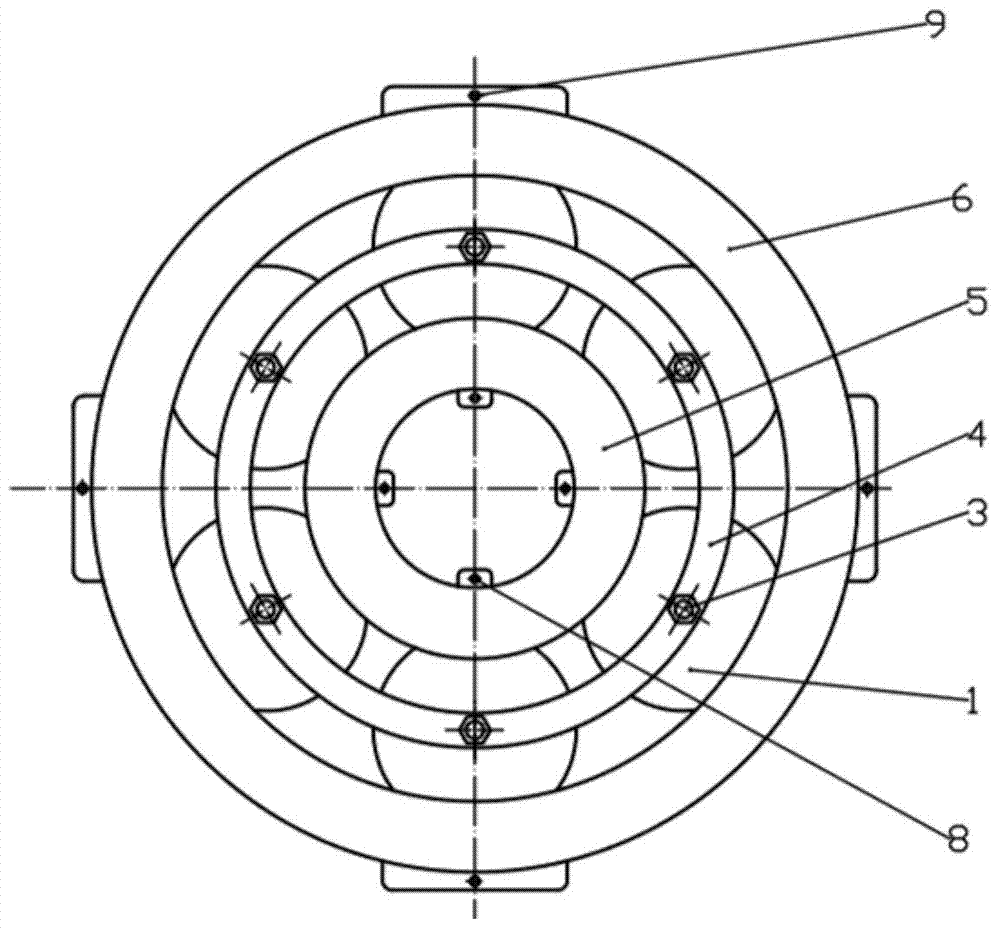

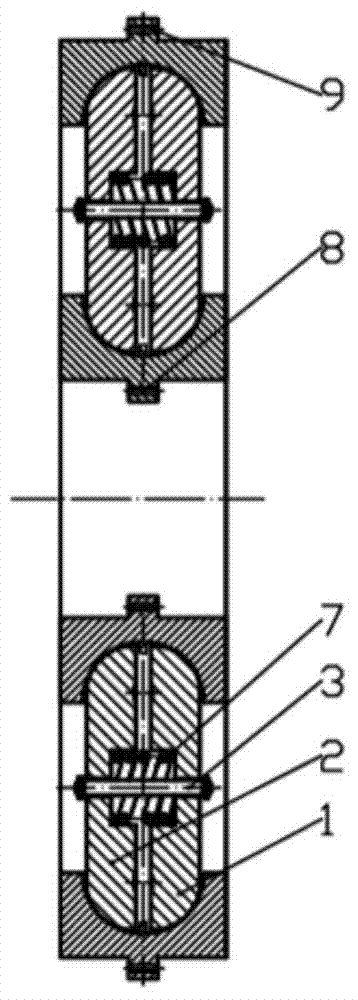

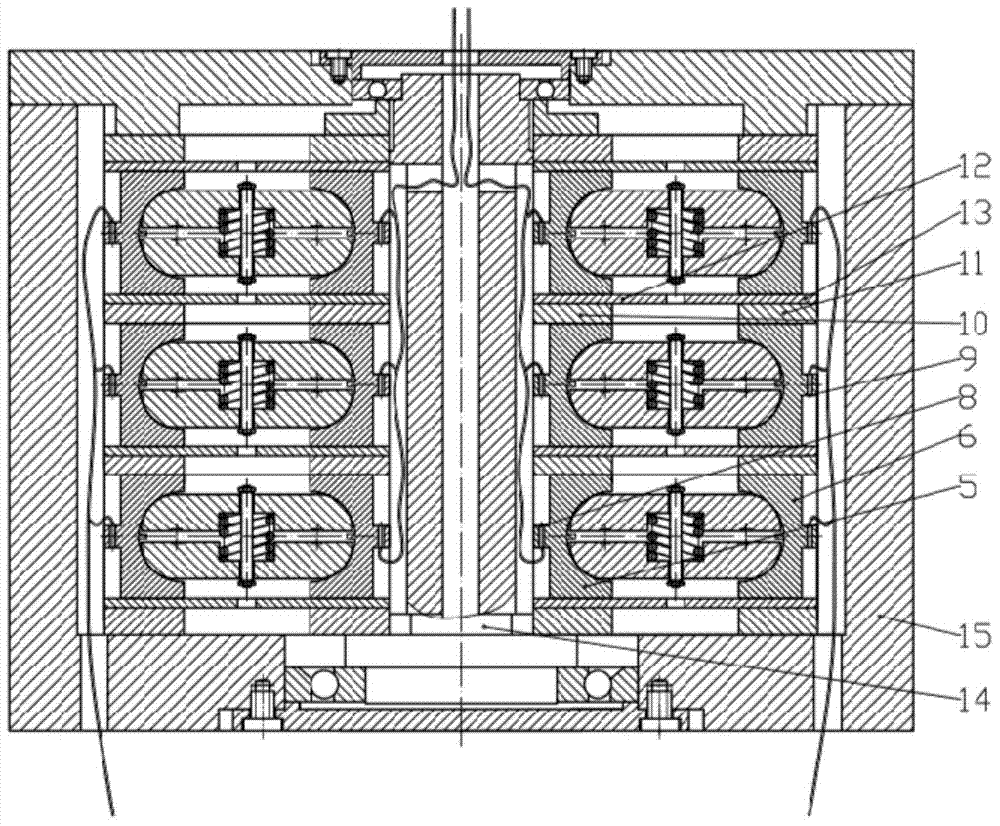

[0019] The present invention proposes a high-power rolling slip ring device, such as figure 1 , figure 2 As shown, a high-power rolling slip ring device of the present invention includes a first coupling 1, a second coupling 2, a coupling shaft 3, a cage 4, an inner ring 5, an outer ring 6, a spring 7, and a first ear hole 8 , the second ear hole 9, the first support frame 10, the second support frame 11, the inner insulating plate 12, the outer insulating plate 13, the main shaft 14 and the box body 15.

[0020] The first coupler 1 and the second coupler 2 are circular truncated structures, and the center of the other end is provided with a cavity, and the couplers are used in pairs; the coupling shaft 3 is installed in the middle of the paired first coupler 1 and second coupler 2 In the cavity, connect the first coupler 1 and the second coupler 2 two by two, and constrain the first coupler 1 and the second coupler 2 to only rotate and move axially along the coupling shaft ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap