An all-in-one machine for cutting and marking water purifier water pipes

A water purifier, integrated machine technology, applied in the direction of shearing device, shearing device, feeding device, etc., can solve the problems of batch size deviation, affecting product quality, inaccurate tube cutting size, etc., and achieves increased transmission. Strength and length, increase the transmission contact area, and eliminate the hidden danger of water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

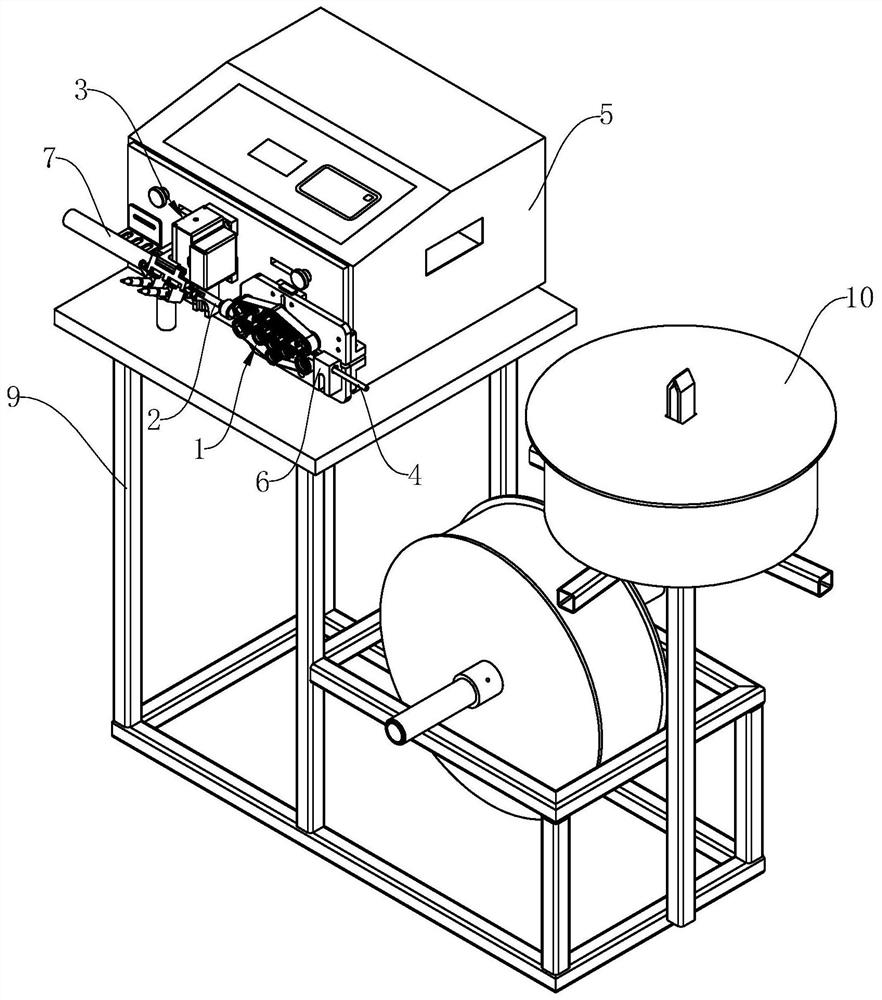

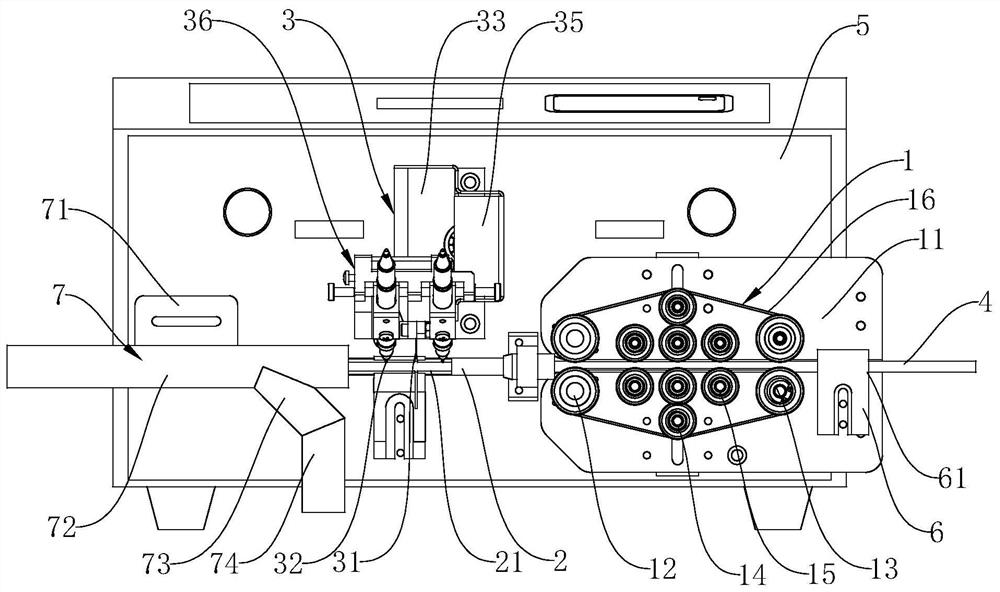

[0025] As shown in the figure, an integrated water purifier water pipe cutting and marking machine includes a feeding mechanism 1, a guide pipe 2, a pipe cutting and marking mechanism 3 and a control mechanism, and the control mechanism is connected to the feeding mechanism 1 and the pipe cutting and marking mechanism respectively. 3 connection, the delivery outlet of the feeding mechanism 1 is aligned with the inlet of the guide pipe 2, and the control mechanism controls the feeding mechanism 1 to transport the water purifier water pipe 4 to the guide pipe 2, and a cutting pipe is provided on the outer wall of the guide pipe 2 and the opening 21 of the marking line, the pipe cutting and marking mechanism 3 is arranged on the top of the guide pipe 2, the pipe cutting and marking mechanism 3 is provided with a blade 31 and a marking pen 32, and the control mechanism controls the blade 31 and the marking pen 32 to the opening 21 The water purifier water pipe 4 is simultaneously c...

Embodiment 2

[0027] This embodiment proposes a water purifier water pipe cutting and scribing integrated machine, which specifically limits the structure of the feeding mechanism 1 on the basis of the first embodiment. In this embodiment, an outer casing 5 is also included, and the control mechanism is arranged in the outer casing 5. The feeding mechanism 1 includes a feeding mounting plate 11 and two reversely running synchronous belt feeding devices that are mirrored up and down. The feeding mounting plate 11 is connected to the outer casing. The side wall of 5 is fixedly connected, and synchronous belt feeding device comprises driving wheel 12, driven wheel 13, tension pulley 14, three positioning wheels 15, conveyor belt 16 and the first driver that is used to drive driving wheel 12 to rotate, and first driver and The control mechanism is connected. Driving wheel 12, driven wheel 13, tensioning wheel 14 and three positioning wheels 15 are all fixed on the vertical mounting surface of f...

Embodiment 3

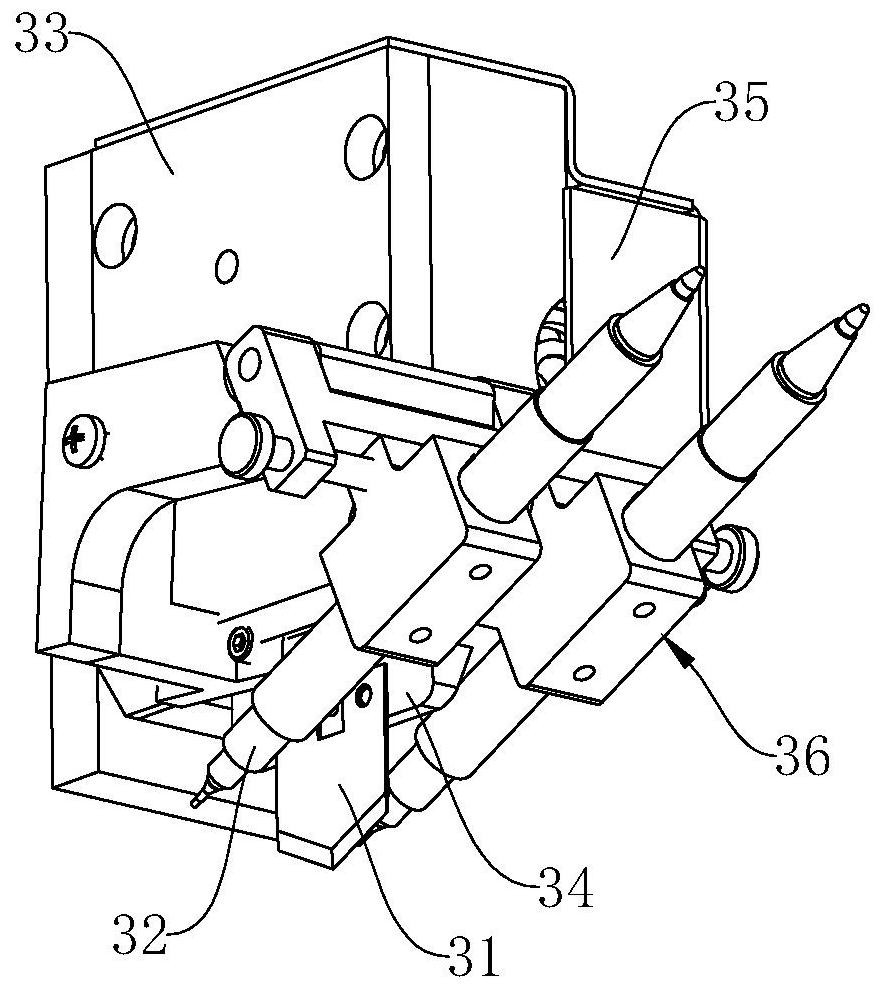

[0030] This embodiment proposes an integrated water purifier water pipe cutting and marking machine, which specifically limits the structure of the pipe cutting and marking mechanism 3 on the basis of the second embodiment. The pipe cutting and marking mechanism 3 includes a fixed base 33, a movable plate 34, a driving device 35 and a marking device 36 arranged on the movable plate 34 for synchronously marking the water pipe 4 of the water purifier. The fixed seat 33 is fixedly connected with the outer side wall of the outer shell 5, the movable plate 34 is movably connected up and down with the fixed seat 33, and the blade 31 is vertically fixedly arranged on the bottom of the movable plate 34, and the blade 31 is an inverted triangle whose apex angle is 120-135° Type, the blade structure can make the cutting edge more flat. A cutting groove 22 is provided on the guide pipe 2 corresponding to the blade 31, and the driving device 35 is used to drive the movable plate 34 to mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com