Protection cover of conical base of ship

A conical and protective cover technology, which is applied to ships and other directions, can solve the problems of being vulnerable to erosion, unfavorable base maintenance, and difficult to effectively resist the threat of natural phenomena, and achieve the effect of strengthening sealing and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

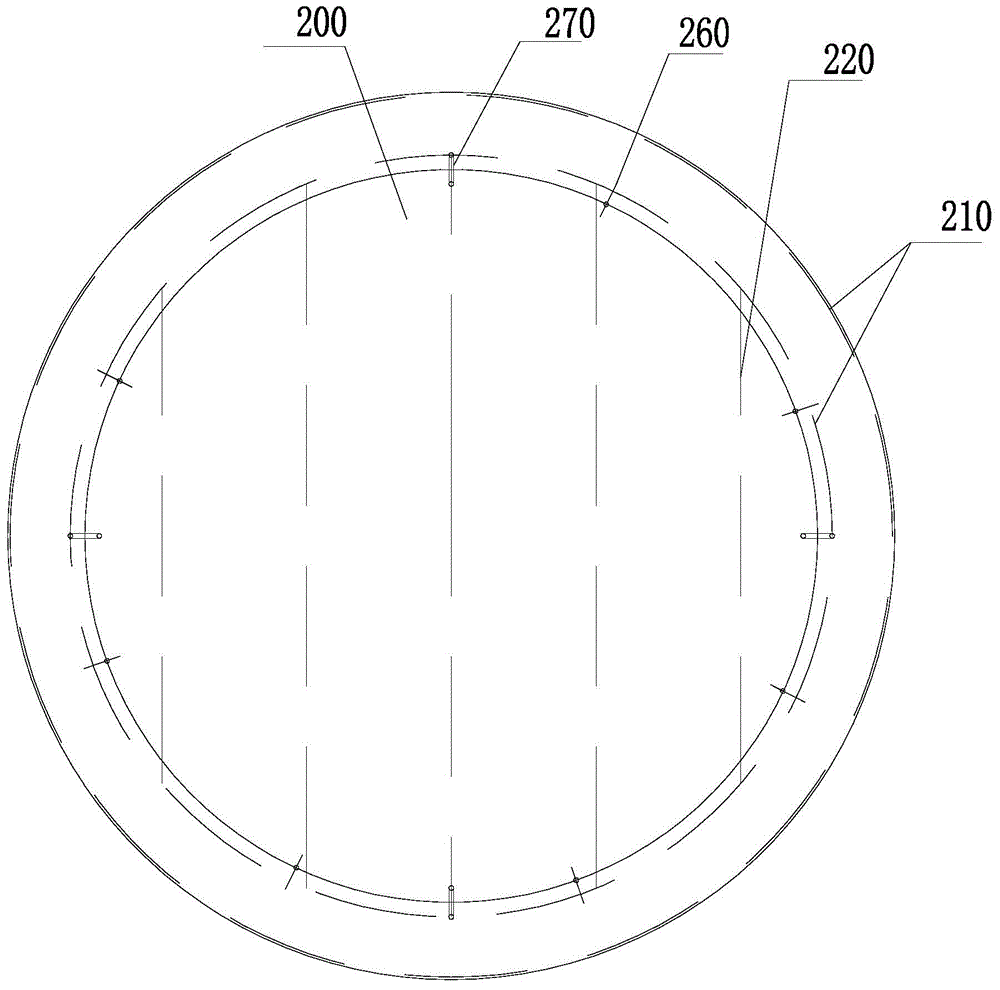

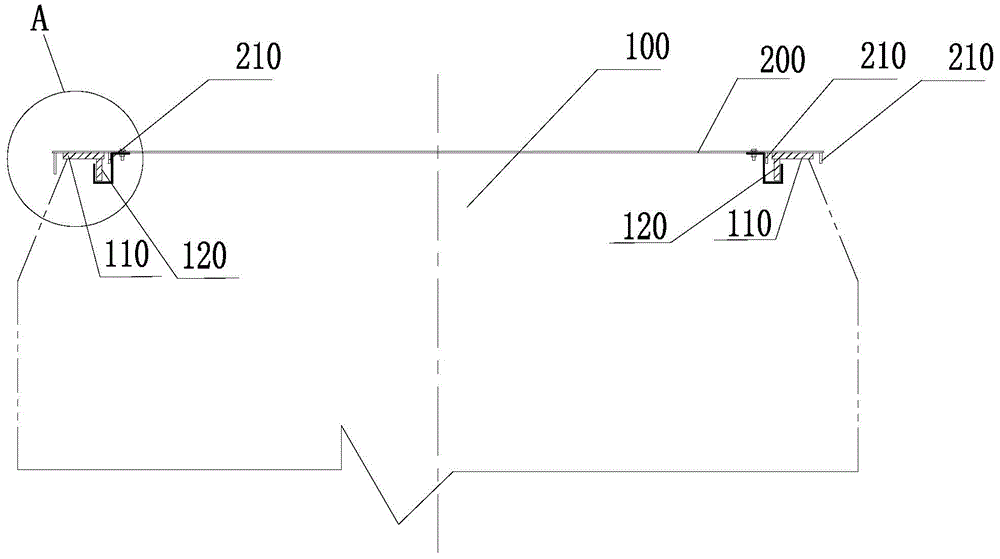

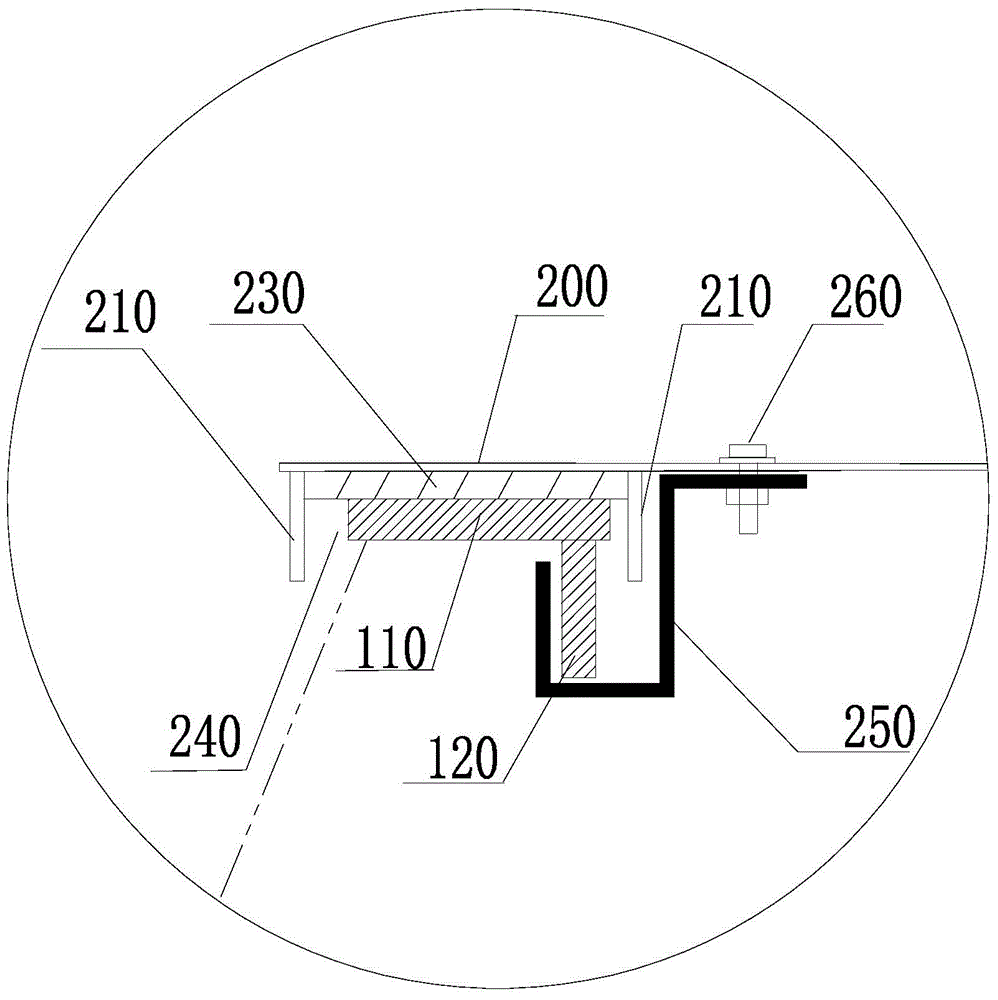

[0020] Please also refer to Figure 1 to Figure 3 , the present embodiment proposes a protective cover for a conical base on a ship, which is used to cover the conical base on a ship. Specifically, it can be as follows figure 2 As shown in the conical base 100, the upper end surface of the conical base 100 is an annular cover plate 110 with a middle opening, and the bottom of the inner ring of the annular cover plate 110 is vertically provided with an annular reinforcing plate 120; The protective cover includes (see image 3 ) a circular cover plate 200, a first reinforcing material 210, a washer 230, and a fastener 250; the first reinforcing material 210 is annularly fixed on the lower surface of the circular cover plate 200, and two groups of first reinforcing An annular groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com