Telescopic pipe locking method and locking mechanism

A locking mechanism and telescopic tube technology, applied in the direction of connecting components, mechanical equipment, rod connections, etc., can solve the problems of unsmooth unlocking and locking, inconvenient unlocking, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

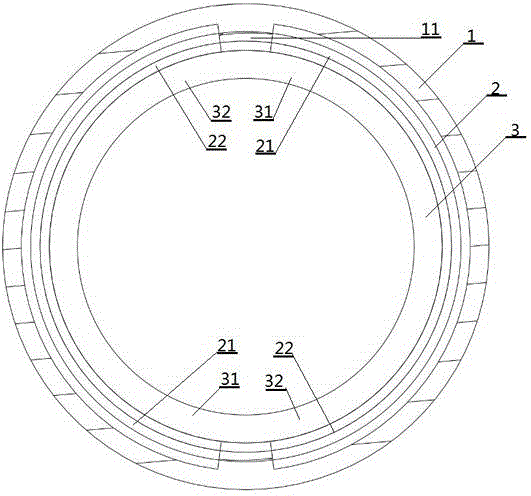

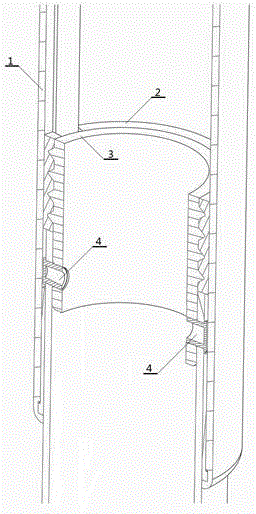

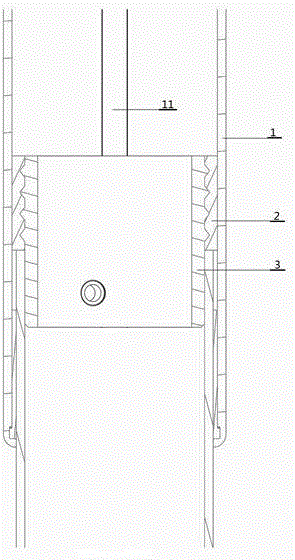

[0016] Such as figure 1 , figure 2 and image 3 As shown, a telescopic tube locking mechanism includes an outer tube 1 and an inner tube 3, and also includes an outer tube wall boss 11 and an intermediate layer 2. The outer tube wall boss 11 is arranged on the inner wall of the outer tube 1, and the middle layer 2 It is arranged between the outer pipe 1 and the inner pipe 3, the inner wall of the middle layer 2 is connected with the outer wall of the inner pipe 3 by threads, the middle layer 2 is an unclosed circular arc, the two ends of the middle layer 2 are in contact with the boss 11 of the outer pipe wall, and the middle Layer 2 includes a middle layer thick-walled part 21 and a middle layer thin-walled part 22. From the middle layer thick-walled part 21 to the middle layer thin-walled part 22, the wall thickness of the middle layer 2 gradually becomes thinner, and the inner tube 3 includes an inner tube wall thickness The part 31 and the inner tube thin-walled par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com