A kind of billet high temperature protective coating and its application

A technology of protective coatings and steel billets, applied in coatings and other directions, can solve problems such as not easy to peel off, and achieve the effects of maintaining compactness, bonding tightly, and ensuring compactness and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

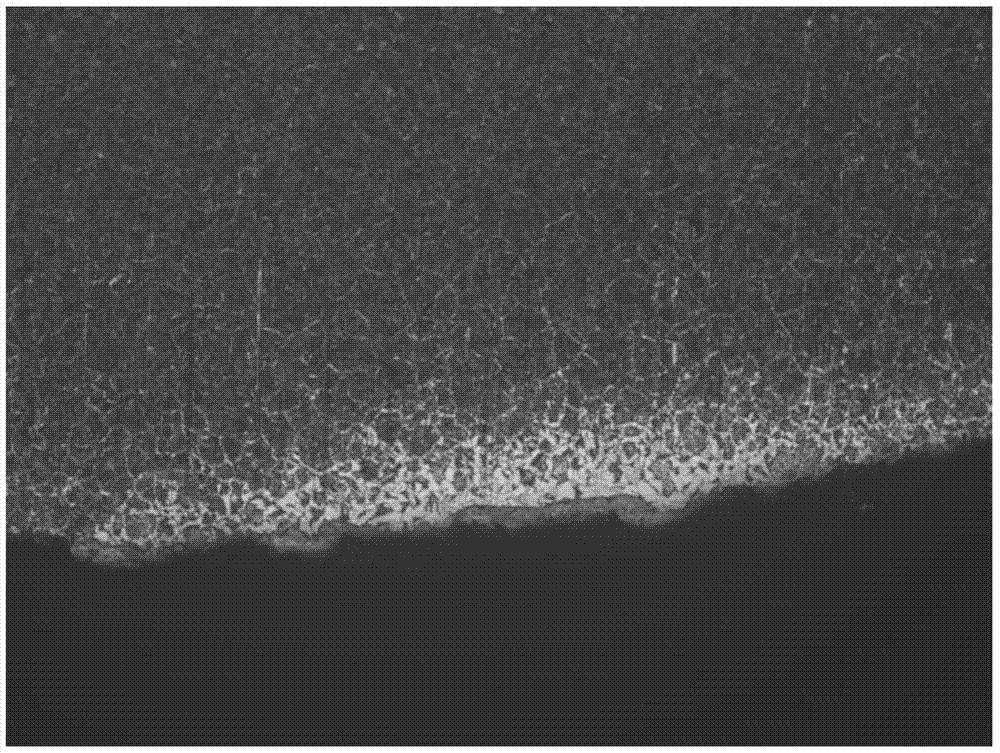

[0024] The application of the billet high-temperature protective coating of the present embodiment comprises the following steps: 45g SiC, 13g SiO 2 , 7gAl 2 o 3 , 3g Cr 2 o 3 . mm. Heat to 1250°C and keep for 2 hours. After the end, the thickness of the decarburized layer is detected to be 0.4mm.

Embodiment 2

[0026] The application of the billet high-temperature protective coating of the present embodiment comprises the following steps: 40g SiC, 10g SiO 2 , 13gAl 2 o 3 , 8g Cr 2 o 3 , 9g of blast furnace slag, 0.2g of sodium hexametaphosphate and 0.2g of cellulose are mixed evenly, and water (96.48g) is added according to the mass ratio of 1:1.2, and the machine is sprayed on the surface of 60Si2CrA steel billet after mixing evenly, and the coating thickness is 0.4mm . Heat to 1250°C and keep for 2 hours. After the end, the thickness of the decarburized layer is detected to be 0.4mm.

Embodiment 3

[0028] The application of the billet high-temperature protective coating of the present embodiment comprises the following steps: 35g SiC, 25g SiO 2 , 16gAl 2 o 3 , 6g Cr 2 o 3 , 5g of blast furnace slag, 0.2g of sodium hexametaphosphate and 0.2g of cellulose are mixed evenly, and water (61.18g) is added according to the mass ratio of 1:0.7. mm. Heat to 1250°C and keep for 2 hours. After the end, the thickness of the decarburized layer is detected to be 0.4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com