Vertical roller height adjustment method and implementation mechanism

A technology of height adjustment and rolling, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of the height of vertical rolling roll is not adjustable, and achieve the effect of convenient, quick and continuous adjustment, and meet the precise requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

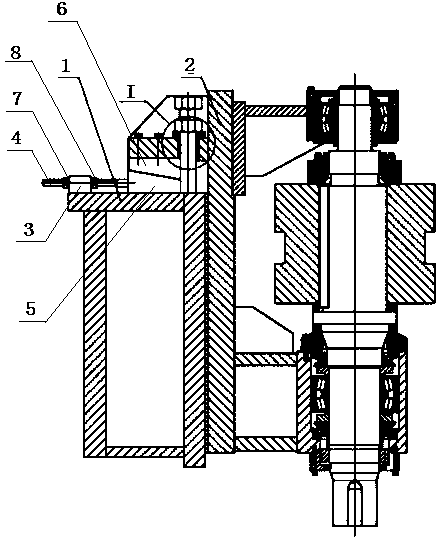

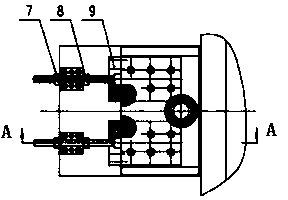

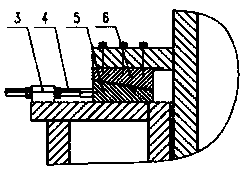

[0013] Such as Figure 1-Figure 5 As shown, the main components of the implementation mechanism of the vertical roll height adjustment method include a fixed frame 1, a roll seat 2, a fixed block 3, an adjustment screw 4, a lower wedge 5, an upper wedge 6, a rear adjustment nut 7, and a front adjustment nut. 8. Coupling block 9, jacking bolt 10, lock nut 11 and internal thread sleeve 12.

[0014] The lower wedge-shaped block 5 is placed on the fixed frame 1, the lower plane of the lower wedge-shaped block 5 is fitted with the upper plane of the fixed frame 1, and the upper surface of the lower wedge-shaped block 5 is an inclined plane. The upper wedge block 6 is installed under the roll seat 2 height limit plates, the upper plane of the upper wedge block 6 is fitted with the lower plane of the limit plate, and the lower surface of the upper wedge block 6 is an inclined plane. The slopes of the lower wedge block 5 and the upper wedge block 6 fit together, and when their relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com