Prestressed real-time monitoring clip anchor and its anchoring method

A real-time monitoring and prestressing technology, which is applied to buildings, building structures, and processing of building materials. The effect of high anchor accuracy, convenient construction, and timely supplementation of the loss value of prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

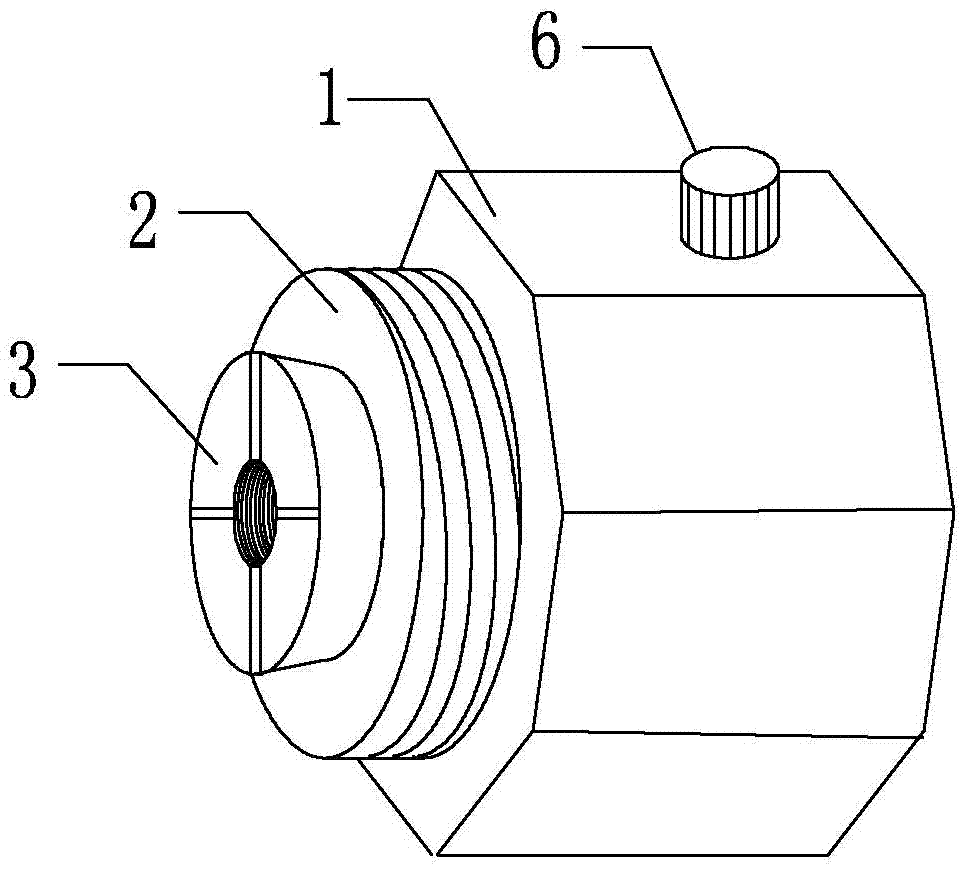

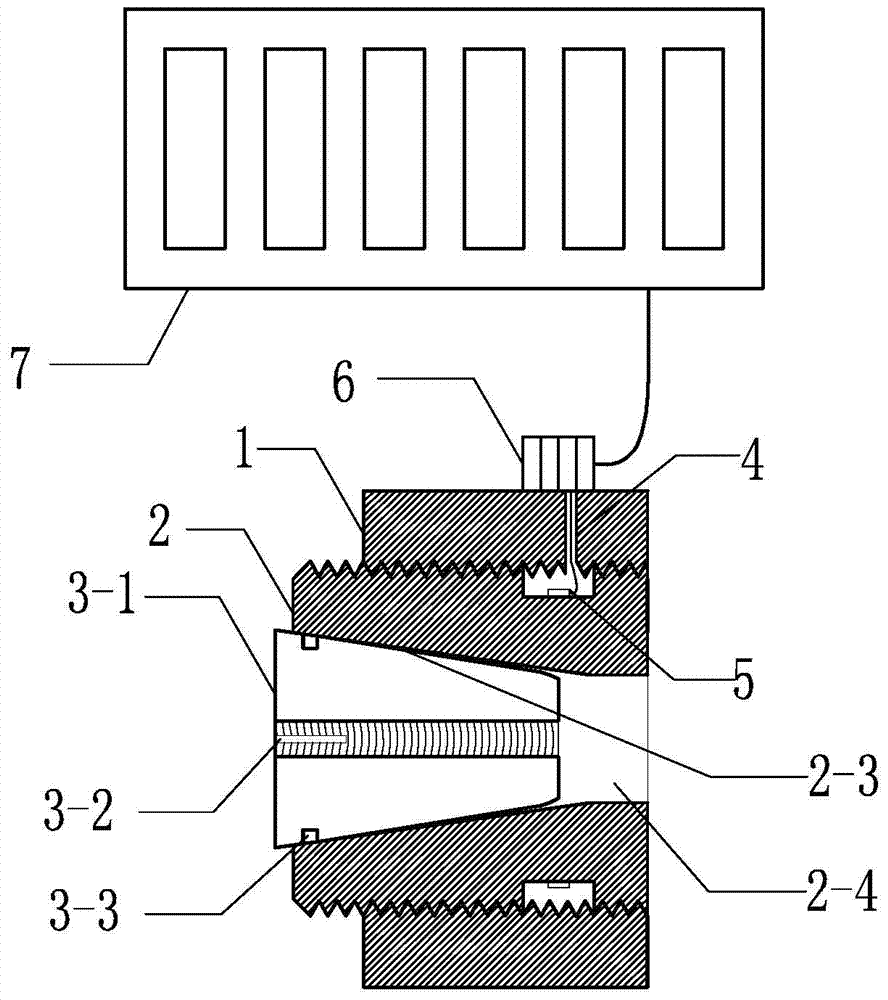

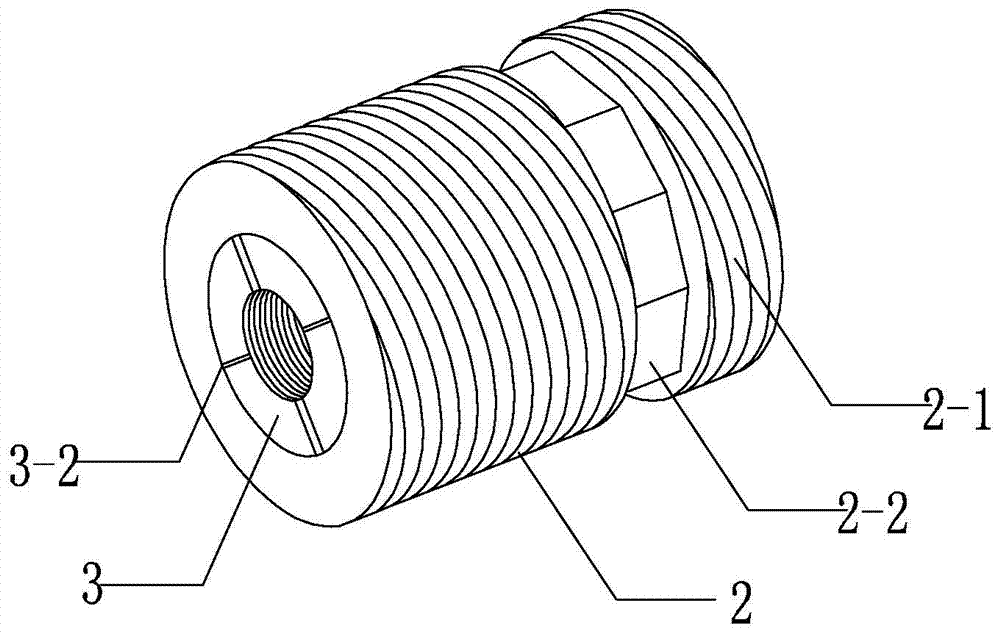

[0017] Specific implementation mode one: as Figure 1~5 As shown, the prestressed real-time monitoring clip anchor of this embodiment includes an outer nut 1, an inner anchor ring 2, a monitor 7, a connector 6 and eight resistance strain gauges 5, and it is characterized in that: the clip anchor It also includes a wedge-shaped cone 3, the outer nut 1 is a regular octagonal nut, the outer nut 1 is processed with a wire channel 4, the outer surface of the inner anchor ring 2 is processed with an outer thread 2-1 along its length direction, and the inner anchor One end of the ring 2 is processed with a wedge-shaped hole 2-3, and the other end of the inner anchor ring 2 is processed with a center hole 2-4. The wedge-shaped hole 2-3 is coaxial and communicated with the center hole 2-4 of the inner anchor ring 2. The small end of the hole 2-3 is connected with the central hole 2-4 of the inner anchor ring 2, and the outer surface of the inner anchor ring 2 is processed with a regula...

specific Embodiment approach 2

[0018] Specific implementation mode two: as figure 2 As shown, in this embodiment, the two strain gauges 5 provided on each side of the strain gauge 5 are arranged perpendicular to each other, adopt temperature self-compensation, and connect to form a Wheatstone full bridge. Such a design can increase the sensitivity of the bridge to 2(1+μ) times, where μ is the Poisson’s ratio of the inner nut 2 of the anchorage. Adds a bend effect. Other components and connections are the same as those in the first embodiment.

[0019] Poisson's ratio: The absolute value of the ratio of the transverse strain caused by a uniformly distributed longitudinal stress to the corresponding longitudinal strain within the proportional limit of the material.

specific Embodiment approach 3

[0020] Specific implementation mode three: as figure 2 As shown, the axial position of the regular octagonal groove 2-2 in this embodiment corresponds to the axial position of the small end of the wedge-shaped hole 2-3. Such a design can avoid too much weakening of the inner nut 2 in the circumferential direction, and can also prevent the inner nut 2 from being too close to the bottom, which will affect the overall mechanical performance of the anchorage. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com