Anchorage device

A technology of anchors and anchor rings, which is applied in the processing of building materials, structural elements, building components, etc., and can solve the problems of long prestressed reserved length, small elastic modulus, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

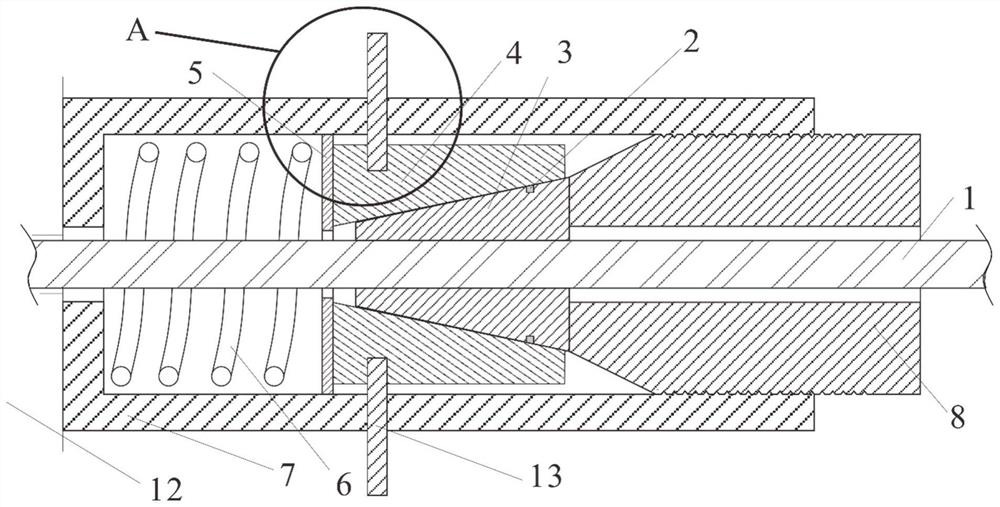

Embodiment 1

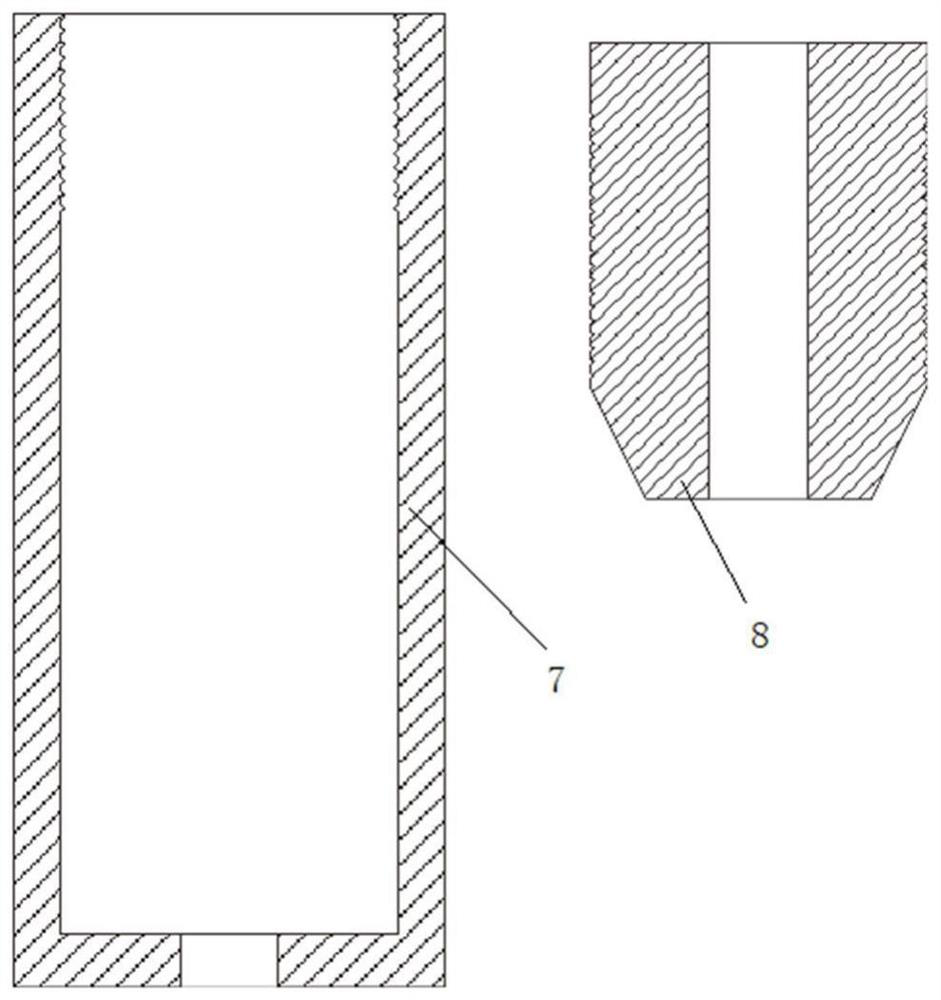

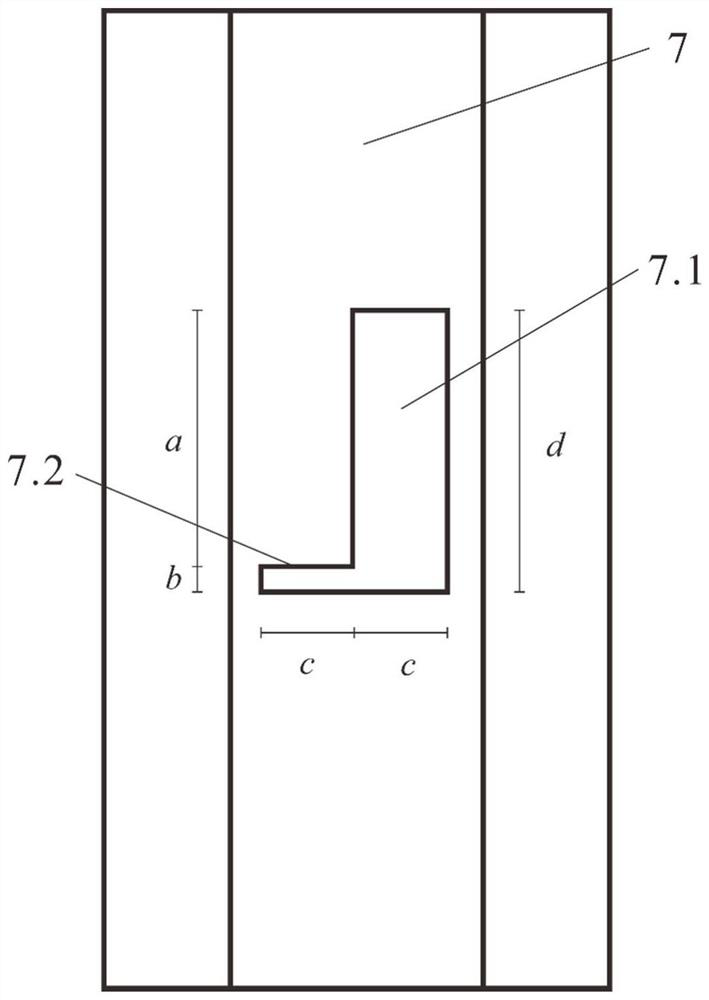

[0039] In embodiment 1: the rigidity K=100.0N / mm of pressing spring 6, then the spring internal force size F s =K·ΔL, ΔL is the compression amount of the spring in the output direction; the inner diameter of the through hole of the outer sleeve 7 is d+10.0mm, the wall thickness is 5.0mm, and the outer wall is made of hexagonal section according to GB / T6170 standard; the outer sleeve 7 two The side is symmetrically opened with an L-shaped slot hole, which can be inserted into the latch 13; the latch 13 can pass through the L-shaped reserved hole on the outer sleeve, and then can be inserted into the prefabricated annular groove on the outer wall of the anchor ring 4, such as image 3 , 4 As shown; the pin is a long strip plate, the length, width and height are e, (b-2) mm and (c-2) mm respectively, and the dimensions of each detail in the figure are: a=35mm, b=5.0mm, c=15.0 mm, d=40.0mm, e=42.0mm, f=7.0mm.

Embodiment 2

[0040] In Example 2: the inner diameter of the through hole of the pressure bearing ring 9 is d+10.0mm, the bottom is a standard hexagonal section, and the inner wall thickness of the thread is 5.0mm; the adjusting nut is produced according to the standard hexagonal nut standard.

Embodiment 3

[0041] In Example 3, the inner diameter of the through hole of the double-stage outer sleeve 11 is d+20.0mm, the wall thickness is 5.0mm, and the outer wall is made of a hexagonal cross-section according to the GB / T6170 standard.

[0042] In addition, between the inner wall of the sleeve and the outer wall of the compression screw, the pressure-bearing washer and the adjusting nut, ordinary threads with a pitch of 1.5mm are used, and the thread length is 40.0mm. The thread pair extrusion resistance, shear strength and thread self-locking performance of the threaded connection satisfy the following relationship:

[0043]

[0044]

[0045]

[0046] In the formula, F u is the axial force; σ t is the allowable extrusion stress of the material; τ t The shear stress required for the material; d s It is the middle diameter of the external thread of the compression screw or the pressure washer; d 1 is the small diameter of the external thread of the compression screw or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com