Through concrete-filled steel tube tied-arch bridge erection construction method

A technology of steel tube concrete and tied arch bridges, which is applied in bridge construction, erection/assembly of bridges, bridges, etc. It can solve problems such as difficult control of high-altitude construction accuracy, long time occupation of waterways, and influence of river navigation, etc., to achieve structural alignment and construction The effect of easy quality control, small impact and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention proposes a new construction method for the erection of a concrete-filled steel tube tie-bar arch bridge. The specific construction process is as follows:

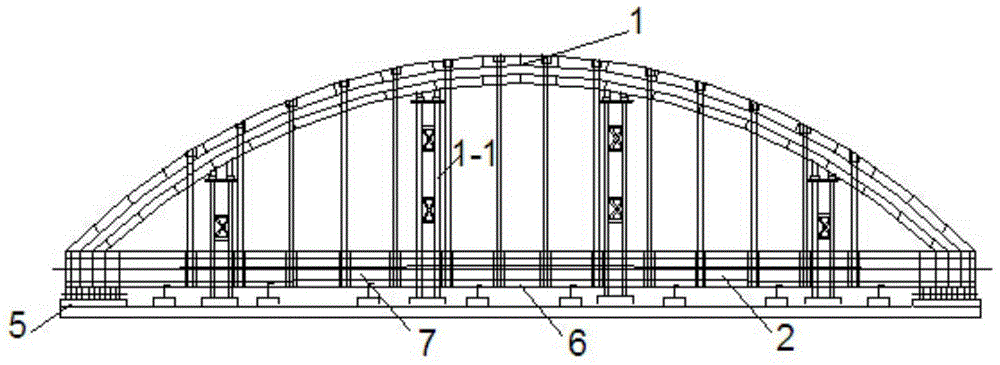

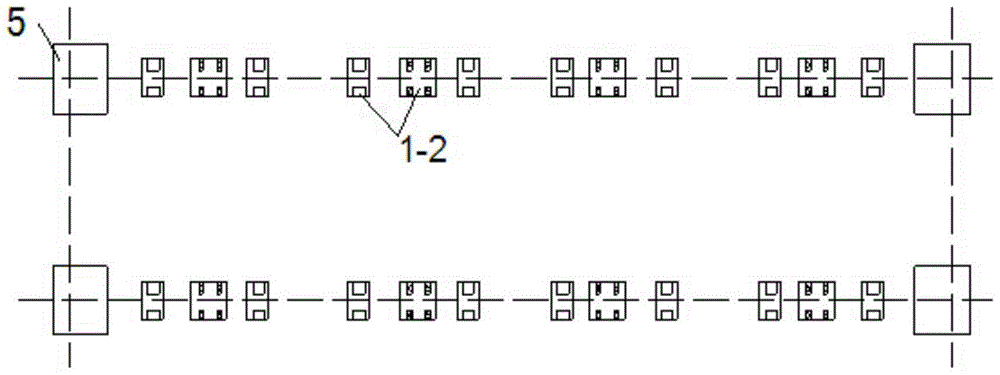

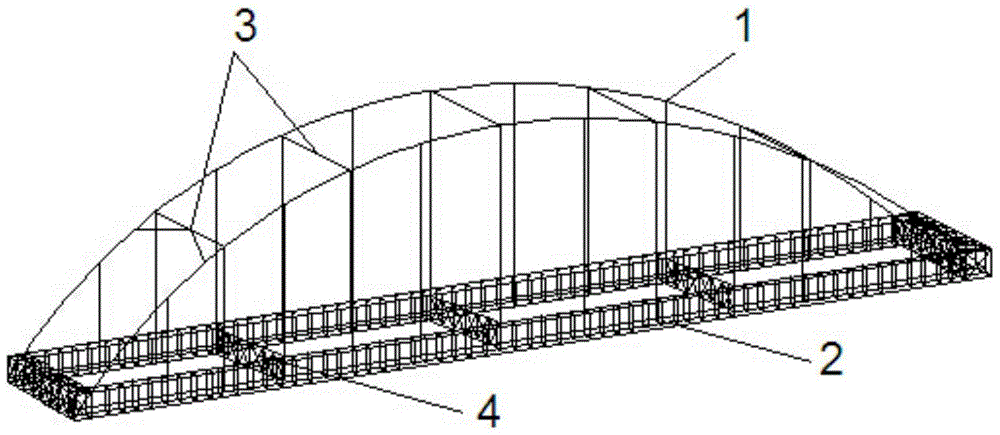

[0067] Step 1: Select a site near the bridge site, and assemble the tire frame on site with high-precision lofting, see Figure 1~Figure 3 ;

[0068] Step 2: Assemble and weld the prefabricated steel pipe arch 1, tie rod stiff frame 2, install wind brace 3 and temporary beam 4, remove temporary fulcrum 5, install tie rod bottom formwork 6 on the stiff frame, bind steel bars, and install inner mold 7, see Figure 1~Figure 3 ;

[0069] Step 3: hoist the steel pipe arch and the tie rod rigid framework in place by using the floating crane 8 as a whole, and pull the wind cable 9 at the same time to ensure its stability, see Figure 4 , Figure 5 ;

[0070] Step 4: Concrete pouring of arch foot 10 and end beam 11, all prestressed bundles 12 of tension end beam, see Figure 6 ;

[0071] Step 5: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com