High speed dispersion machine suitable for high-viscosity and heavy materials

A high-speed disperser and high-viscosity technology, which is applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of poor stirring effect and low stirring efficiency, prevent eddy current, improve stirring effect and stirring efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

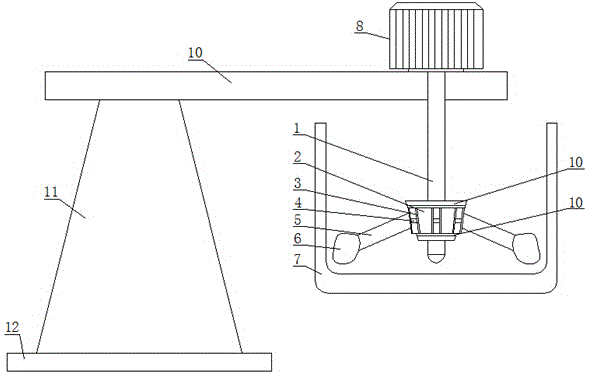

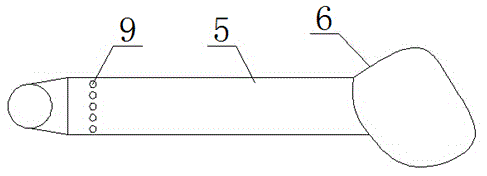

[0029]The high-speed dispersing machine suitable for high-viscosity thick and heavy materials in this embodiment includes a base, a support column is provided on the base, a workbench is provided at the upper end of the support column, and a rotating motor is provided on the workbench. The rotating motor is connected with a stirring shaft, and the lower end of the stirring shaft is provided with a conical connecting plate, and at least 4 connecting grooves are uniformly connected on the conical connecting plate, and a pin shaft is arranged in the connecting groove, and the pins The shaft is connected with a stirring rod, one end of the stirring rod is connected with the pin shaft, and the other end of the stirring rod is connected with a stirring piece; the upper end and the lower end of the connecting groove are provided with limit blocks for limiting the movement position of the stirring rod; Stirring rods connected to adjacent connecting grooves have different lengths.

Embodiment 2

[0031] The high-speed dispersing machine suitable for high-viscosity thick and heavy materials in this embodiment includes a base, a support column is provided on the base, a workbench is provided at the upper end of the support column, and a rotating motor is provided on the workbench. The rotating motor is connected with a stirring shaft, and the lower end of the stirring shaft is provided with a conical connecting plate, and at least 4 connecting grooves are uniformly connected on the conical connecting plate, and a pin shaft is arranged in the connecting groove, and the pins The shaft is connected with a stirring rod, one end of the stirring rod is connected with the pin shaft, and the other end of the stirring rod is connected with a stirring piece; the upper end and the lower end of the connecting groove are provided with limit blocks for limiting the movement position of the stirring rod; Stirring rods connected to adjacent connecting grooves have different lengths; the ...

Embodiment 3

[0033] The high-speed dispersing machine suitable for high-viscosity thick and heavy materials in this embodiment includes a base, a support column is provided on the base, a workbench is provided at the upper end of the support column, and a rotating motor is provided on the workbench. The rotating motor is connected with a stirring shaft, and the lower end of the stirring shaft is provided with a conical connecting plate, and at least 4 connecting grooves are uniformly connected on the conical connecting plate, and a pin shaft is arranged in the connecting groove, and the pins The shaft is connected with a stirring rod, one end of the stirring rod is connected with the pin shaft, and the other end of the stirring rod is connected with a stirring piece; the upper end and the lower end of the connecting groove are provided with limit blocks for limiting the movement position of the stirring rod; The lengths of the stirring rods connected to the adjacent connecting grooves are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com