Leachate diversion blind pipe laying system

A technology of leachate and blind pipe, applied in the field of environmental engineering, can solve problems such as failure to meet leachate removal requirements, breakage, blockage, etc., achieve better treatment effect, improve stability, and reduce residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention are described in detail as follows:

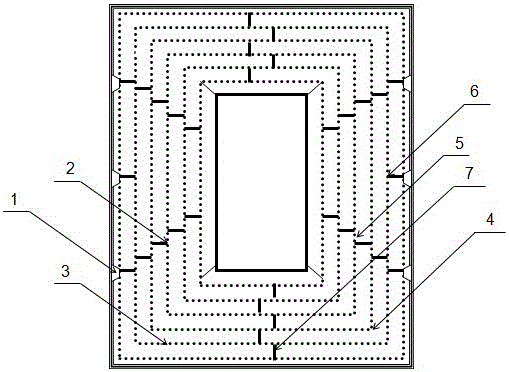

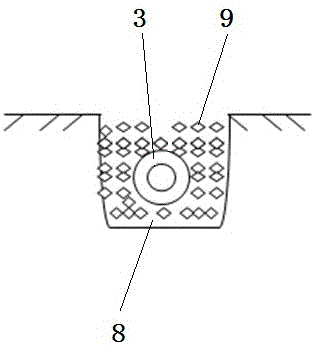

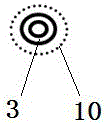

[0019] In this example, see Figure 1 ~ Figure 4 , a leachate diversion blind pipe laying system, laying an annular diversion pipe 3 in a diversion blind ditch 8 excavated at the bottom of the landfill to form an annular anti-seepage system, the depth of the diversion blind ditch 8 and The widths are 1.0m and 0.8m respectively, the connecting pipe 2 adopts HDPE pipe DE160 specification, the corner of diversion blind ditch 8 is connected with HDPE pipe DE160 90° elbow 4 of the same specification as diversion pipe 3, and the diversion pipe 3. After wrapping the outer cladding pipe for 10, fix it in the diversion blind ditch 8 with stone filler 9. The stone filler 9 will completely cover the diversion pipe 3. Since the blind ditch 8 is based on waste and garbage, garbage is prone to occur For digestion and settlement, in order to maintain its stability, stone filler 9 is used to cover the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com