Auxiliary construction method for long-span cantilever integral laminated vierendeel truss structure

A technology of large-span cantilever and hollow truss, applied in the field of auxiliary construction, can solve the problems of large cantilever span and high cantilever height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The auxiliary construction method of a large-span cantilevered integrally laminated vierendeel truss structure is used for a reinforced concrete integrally laminated vierendeel truss structure with a cantilevered span of 8.4m and a stacked number of 4 layers. The steps include:

[0027] Step 1. Construction of cantilevered reinforced concrete vierendeel truss.

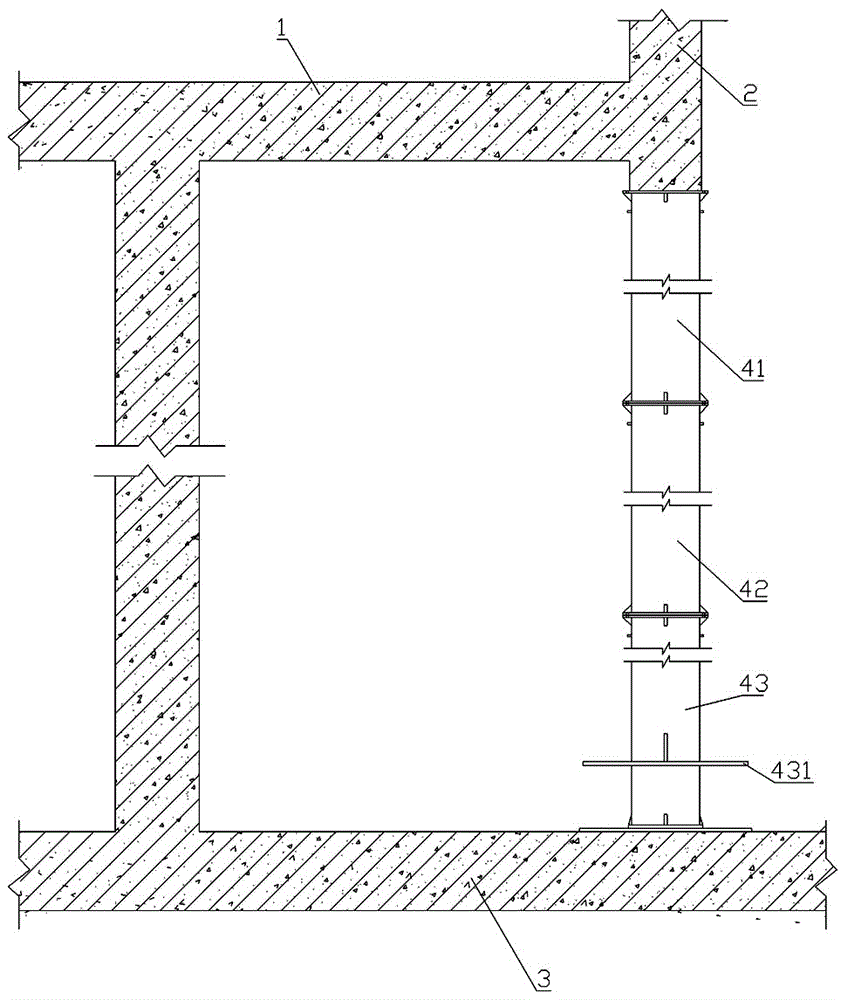

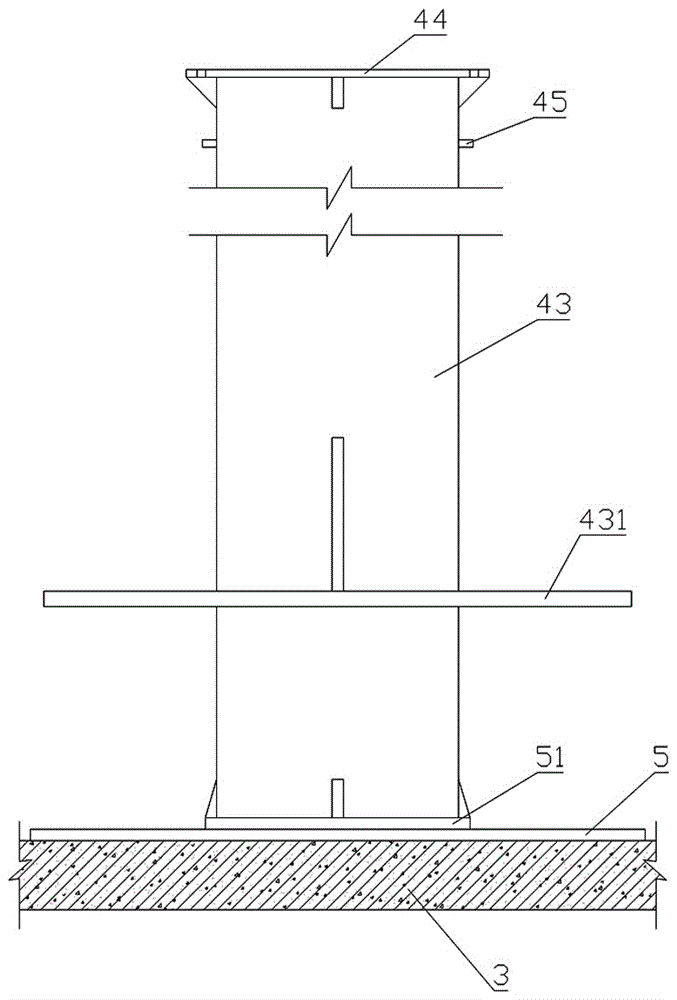

[0028] refer to figure 1 , the cantilevered reinforced concrete vierendeel truss includes a cantilevered beam 1 with a reinforced concrete structure and a pillar 2 with a reinforced concrete structure. According to the prior art, a high formwork support system is set up on the first floor floor 3 to support and make the cantilevered beam 1 .

[0029] Step 2. Construction of temporary support system for steel structure columns.

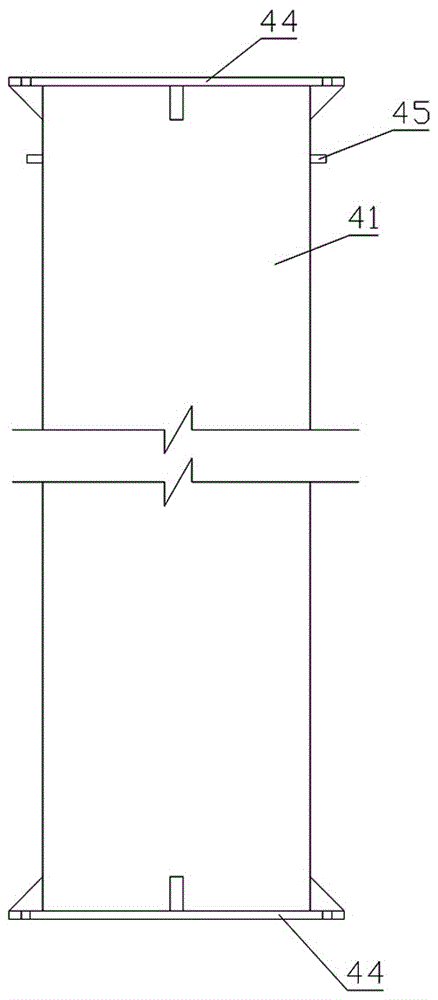

[0030] refer to Figure 1 to Figure 3 , the steel structure column temporary support system is composed of several steel structure columns, and a steel structure column is set up at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com