A method for preparing cigarettes from cigarette beads obtained by pan-processing method

A technology of cigarettes and tobacco beads, which is applied in the manufacture of paper cigarettes, applications, tobacco, etc., can solve problems such as the inability to guarantee the formula of shredded tobacco, the distribution of shredded tobacco, and the fluctuation of quality stability, so as to achieve uniform cigarette formula, prolong combustibility, and coordination Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

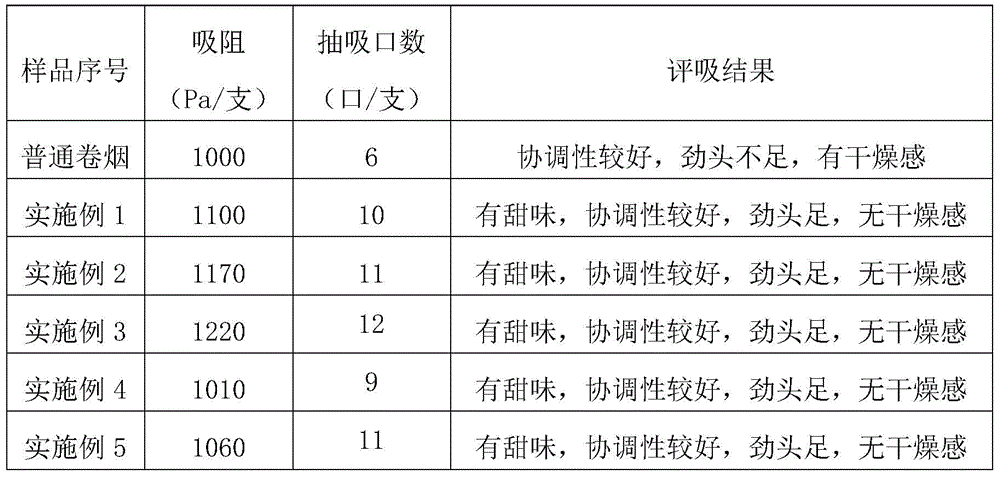

Examples

Embodiment 1

[0024] A method for preparing cigarettes, comprising the following steps:

[0025] 1) Pulverize the cigarette leaves into fine powder, put it in the coating pan, and spray syrup with a weight concentration of 70% into the fine powder under the rotation of the coating pan to moisten the fine powder and roll it into small particles. Continue to sprinkle fine powder into the granules and roll them to make the small granules solid and dense, then spray syrup and sprinkle powder, and repeat the operation until it becomes a regular-shaped pellet mold, and then spray syrup and powder after screening until the pellets Molded into pellets with a particle size range of 0.8-1.5mm, and dried to obtain smoke beads;

[0026] 2) Add 0.5% (weight) of carrageenan powder to the smoke beads, mix evenly, put it into a mold and feed steam at 120°C, and apply 1.2Kg / cm2 at the same time 2 Press the smoke beads into smoke sticks;

[0027] 3) Wrap the cigarette stick with tipping paper, connect it w...

Embodiment 2

[0029] A method for preparing cigarettes, comprising the following steps:

[0030] 1) Pulverize the cigarette leaves into fine powder, put it in the coating pan, spray syrup with a weight concentration of 50% into the fine powder under the rotation of the coating pan, make the fine powder moist and roll into small particles, Continue to sprinkle fine powder into the granules and roll them to make the small granules solid and dense, then spray syrup and sprinkle powder, and repeat the operation until it becomes a regular-shaped pellet mold, and then spray syrup and powder after screening until the pellets Molded into pellets with a particle size range of 1-2mm, and dried to obtain smoke beads;

[0031] 2) Add 1% (weight) xanthan gum powder to the smoke beads, mix evenly, put it into a mold and feed steam at 140°C, and apply 1Kg / cm2 at the same time 2 Press the smoke beads into smoke sticks;

[0032] 3) Wrap the cigarette stick with tipping paper, connect it with a filter, and...

Embodiment 3

[0034] A method for preparing cigarettes, comprising the following steps:

[0035] 1) Pulverize the cigarette leaves into fine powder, put it in the coating pan, and spray syrup with a weight concentration of 80% into the fine powder under the rotation of the coating pan, so that the fine powder is moistened and rolled into small particles. Continue to sprinkle fine powder into the granules and roll them to make the small granules solid and dense, then spray syrup and sprinkle powder, and repeat the operation until it becomes a regular-shaped pellet mold, and then spray syrup and powder after screening until the pellets Molded into pellets with a particle size range of 0.5-1.2mm, and dried to obtain smoke beads;

[0036] 2) Add 0.2% (weight) gelatin powder to the smoke beads, mix evenly, put it into a mold and feed steam at 110°C, and apply 1.5Kg / cm2 at the same time 2 Press the smoke beads into smoke sticks;

[0037] 3) Wrap the cigarette stick with tipping paper, connect i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com