Oil return device at the bottom of the filter element of the oil and gas separator

A technology of oil-gas separator and filter element, which is applied to parts of pumping devices for elastic fluids, machines/engines, rotary piston type/oscillating piston type pump components, etc., which can solve the problems of increasing the overall height of the unit, and achieve Guarantee the effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

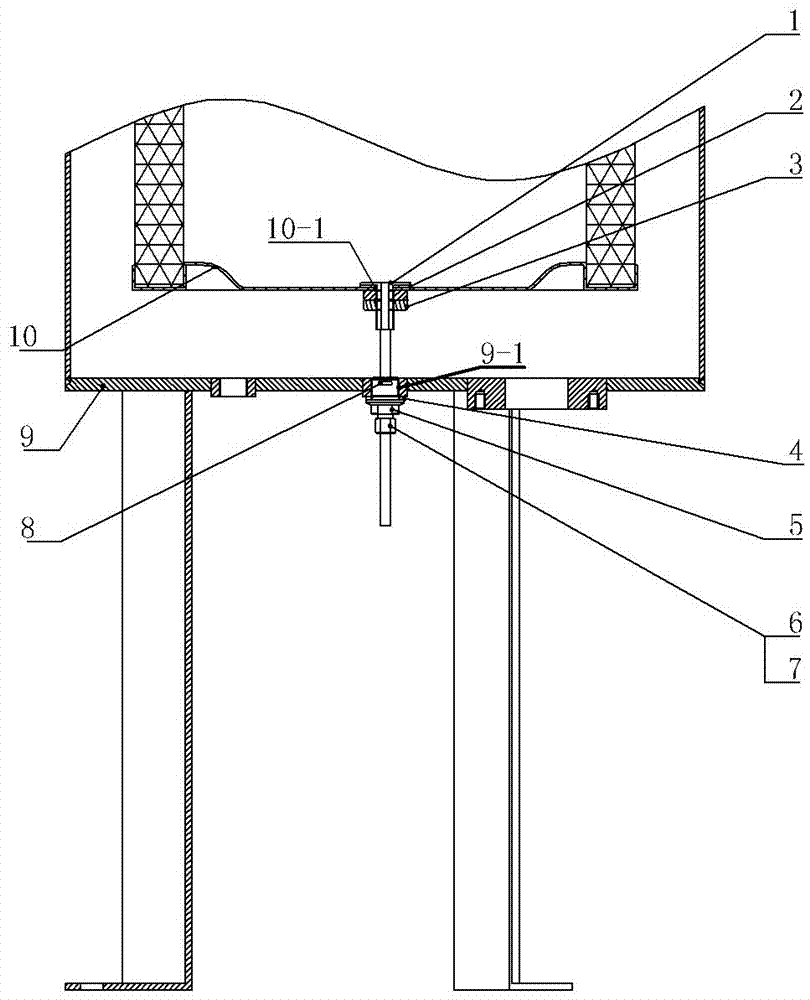

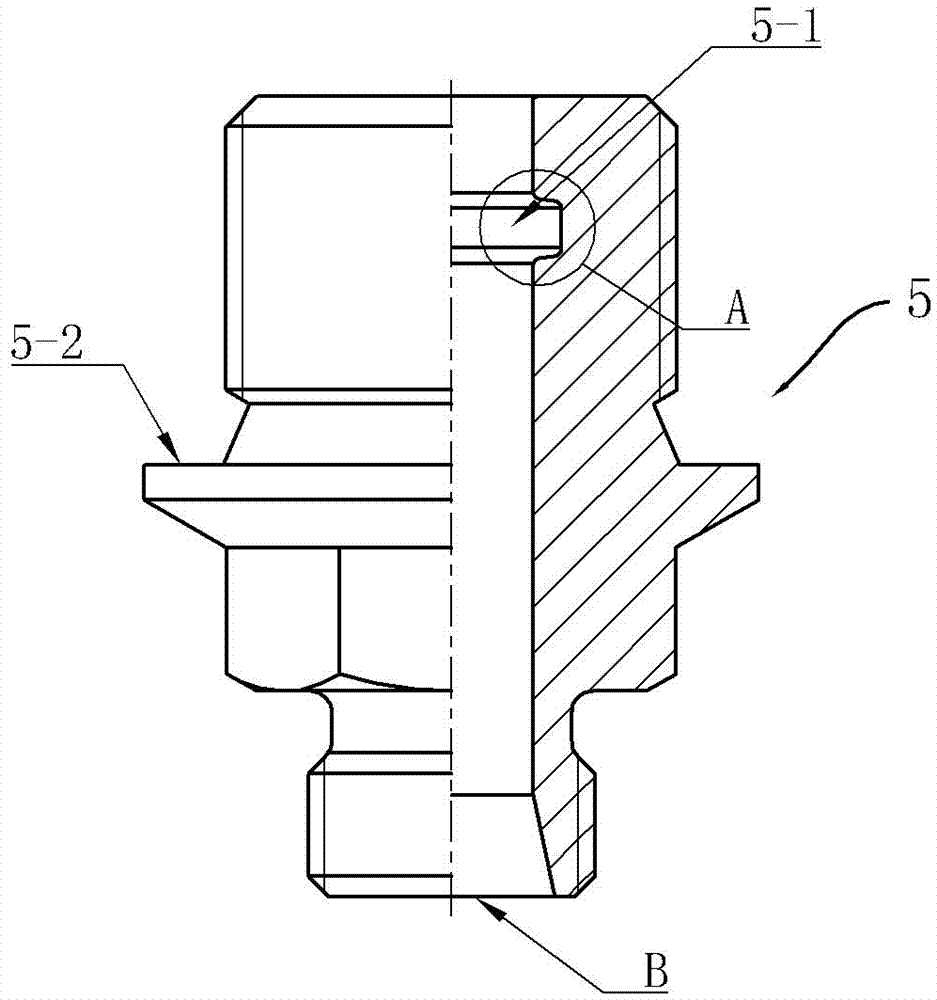

[0017] See figure 1 , the oil return device at the bottom of the oil-gas separator filter element of the present invention, which includes an oil-gas separator filter element 10, an oil-gas separator cylinder body 9 and an oil return pipe assembly 1, an installation hole 10-1 is opened at the bottom of the oil-gas separator filter element 10, and the oil-gas separator cylinder There is a mounting hole 9-1 at the bottom of the body 9, and the oil return pipe assembly 1 passes through the mounting hole of the oil-gas separator filter element 10 and the mounting hole of the oil-gas separator cylinder 9 in turn, and passes between the oil return pipe assembly 1 and the oil-gas separator filter element. The lock nut 3 is locked, and the oil return pipe assembly 1 and the cylinder body 9 of the oil-gas separator are connected and fixed through the ferrule joint 5 .

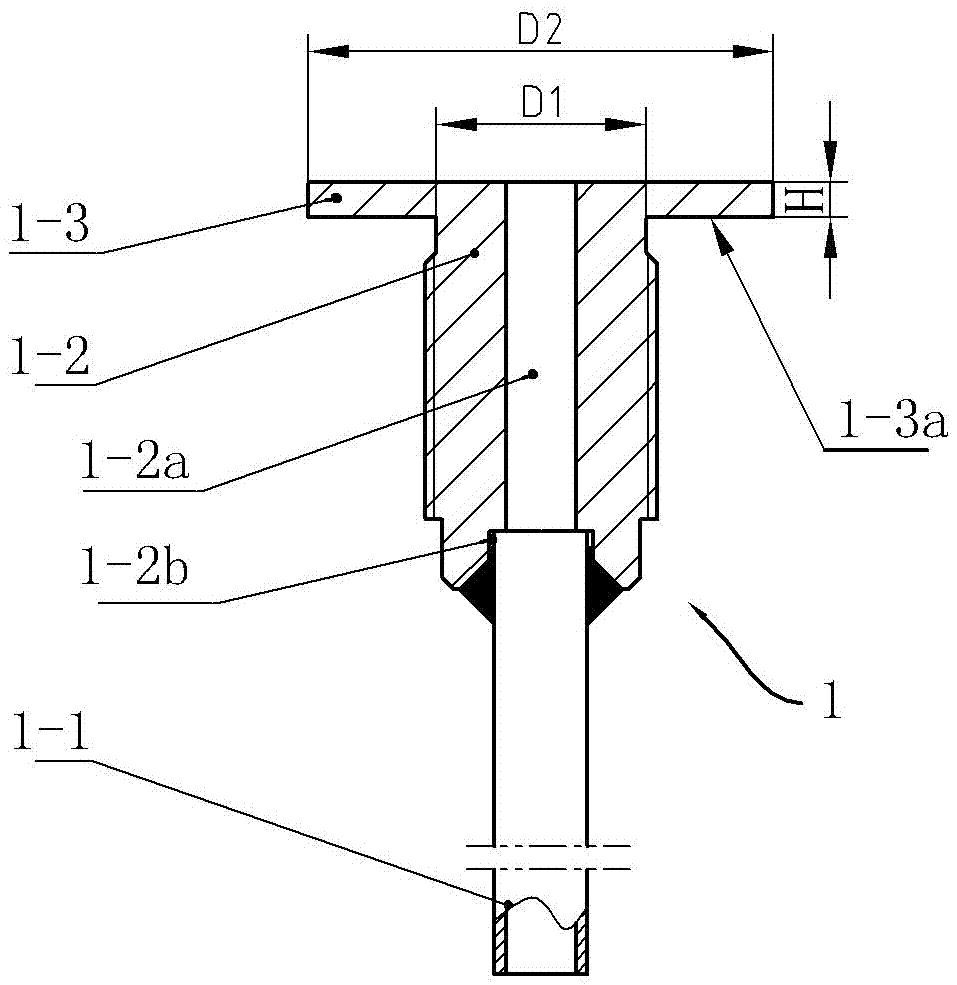

[0018] See figure 2 , the oil return pipe assembly 1 includes an oil return pipe 1-1 and a plate-through joint 1-2,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap