Large crosshead diesel engine

A diesel engine, crosshead technology, applied in the direction of the crosshead, engine components, engine frame, etc., to achieve the effect of improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

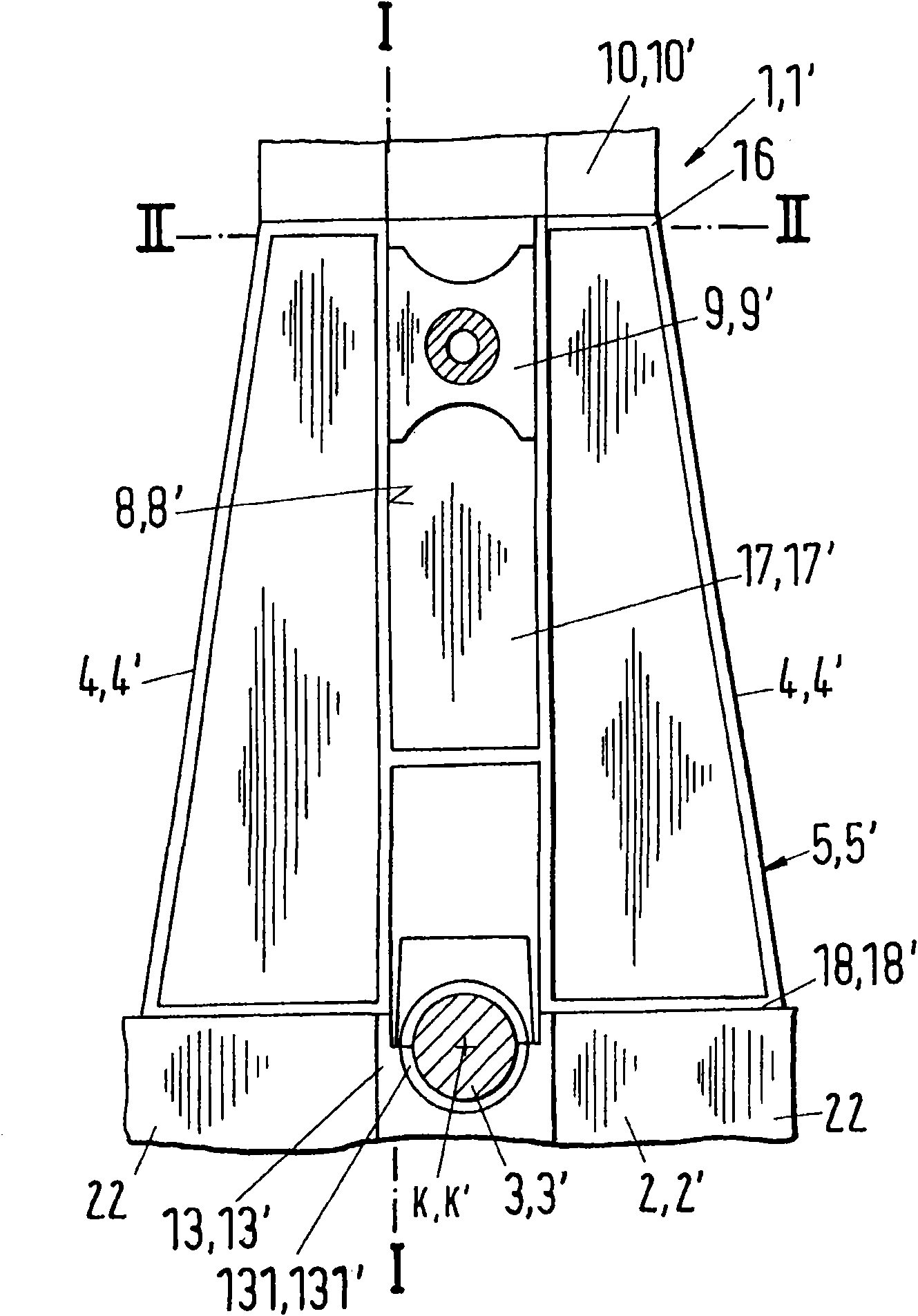

[0049] The large-scale crosshead diesel engine according to the invention, indicated generally by the reference numeral 1 hereinafter, is manufactured in particular as a two-stroke large-scale diesel engine with once-through scavenging, eg widely used in shipbuilding.

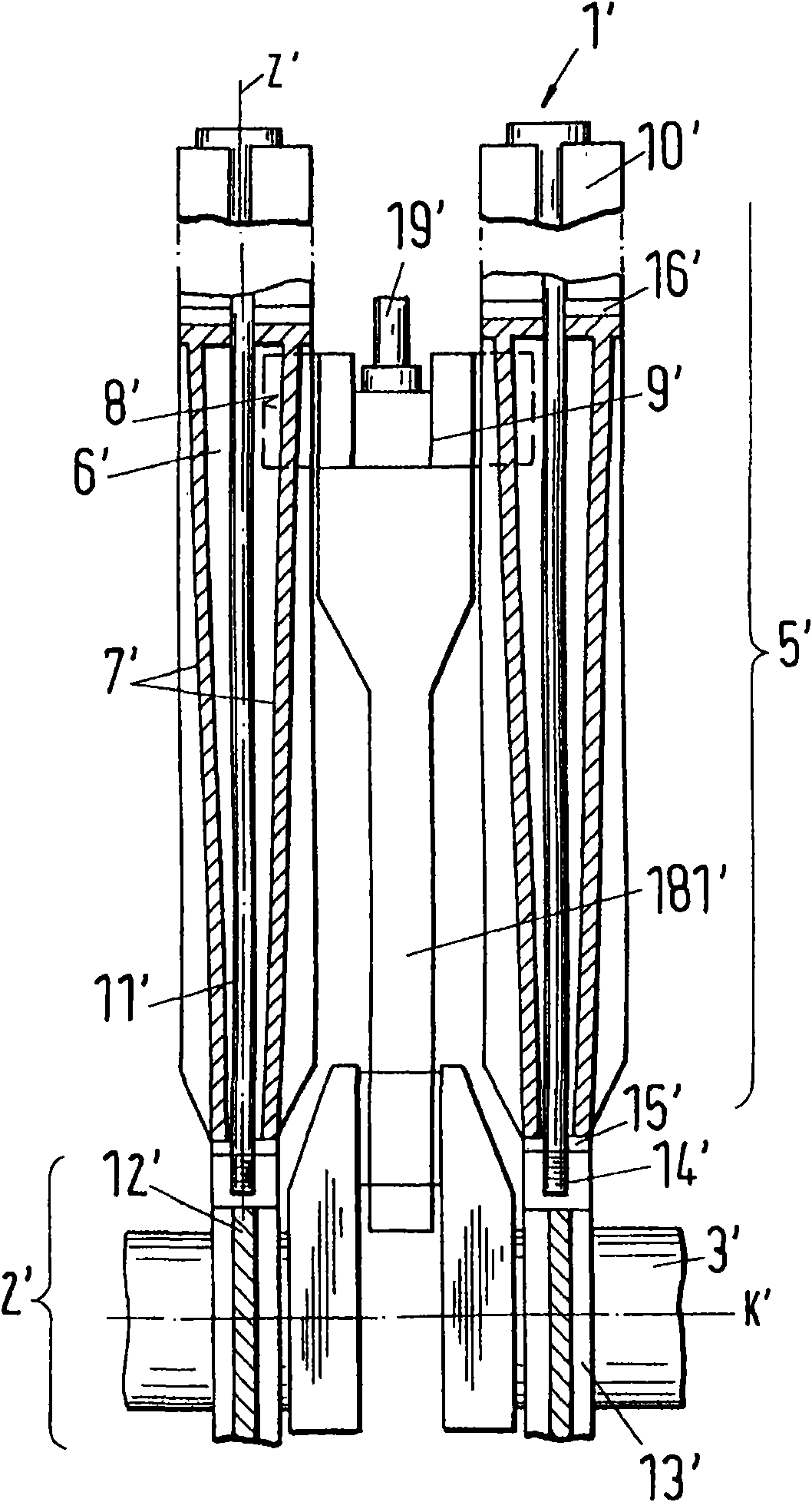

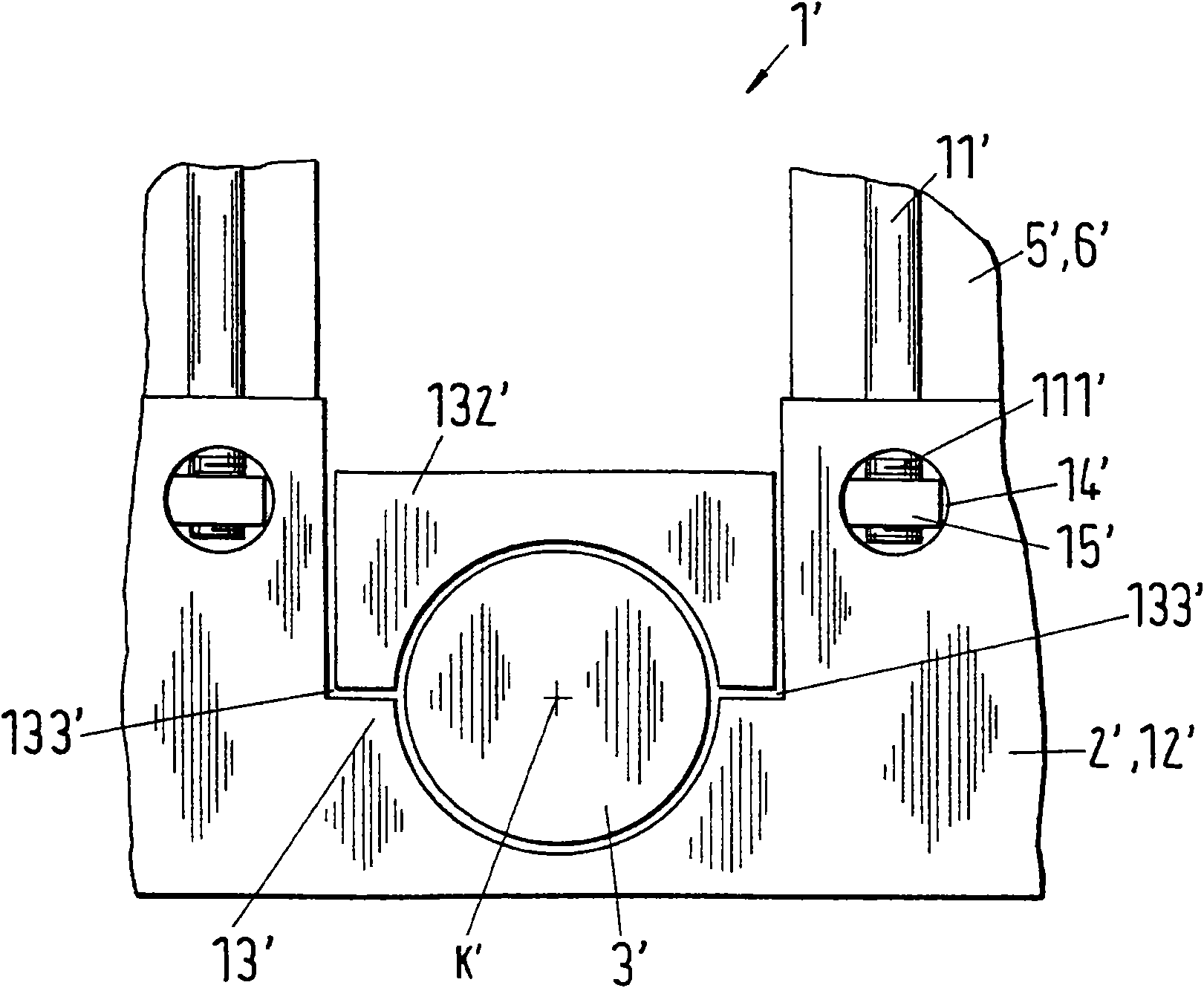

[0050] In the further description, reference will be made to figure 2 and image 3 The design of a known large crosshead diesel engine from the prior art is discussed for purposes of illustration and description of the present invention. In the description of the prior art that differs from the present invention, those features relating to engines known from the prior art are provided with an apostrophe, whereas features according to the present invention are denoted by reference numerals without an apostrophe.

[0051] figure 1 The general design of a large crosshead diesel engine 1 , 1 ′ is shown schematically in cross-section, for example already known in the prior art, but can in principle also be imple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap