Rotatable orifice plate for direct flow measurement

A flow measurement, orifice plate technology, applied in the detection of fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, valve devices, etc., can solve problems such as occupying space and increasing head loss in pressure-related systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

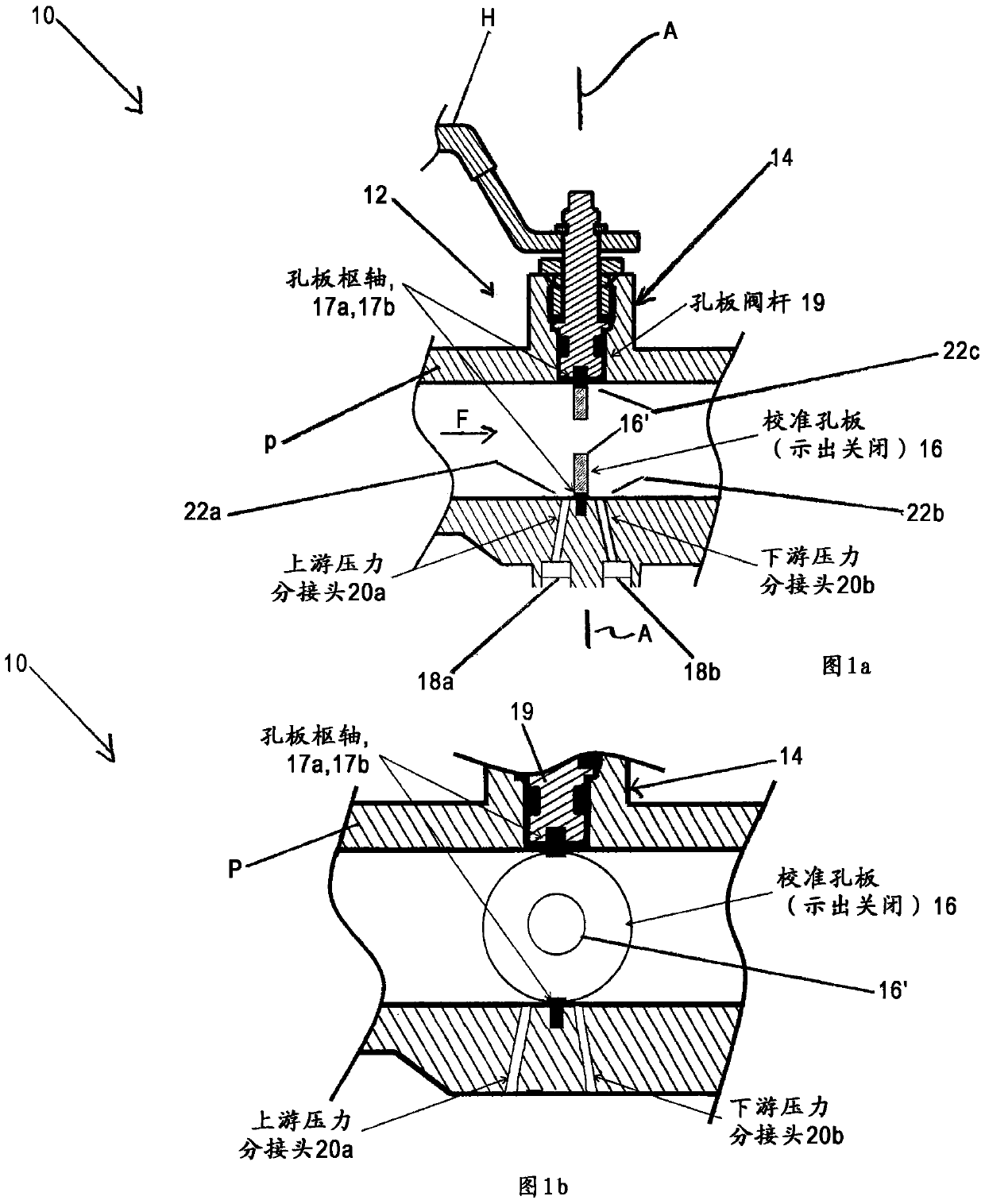

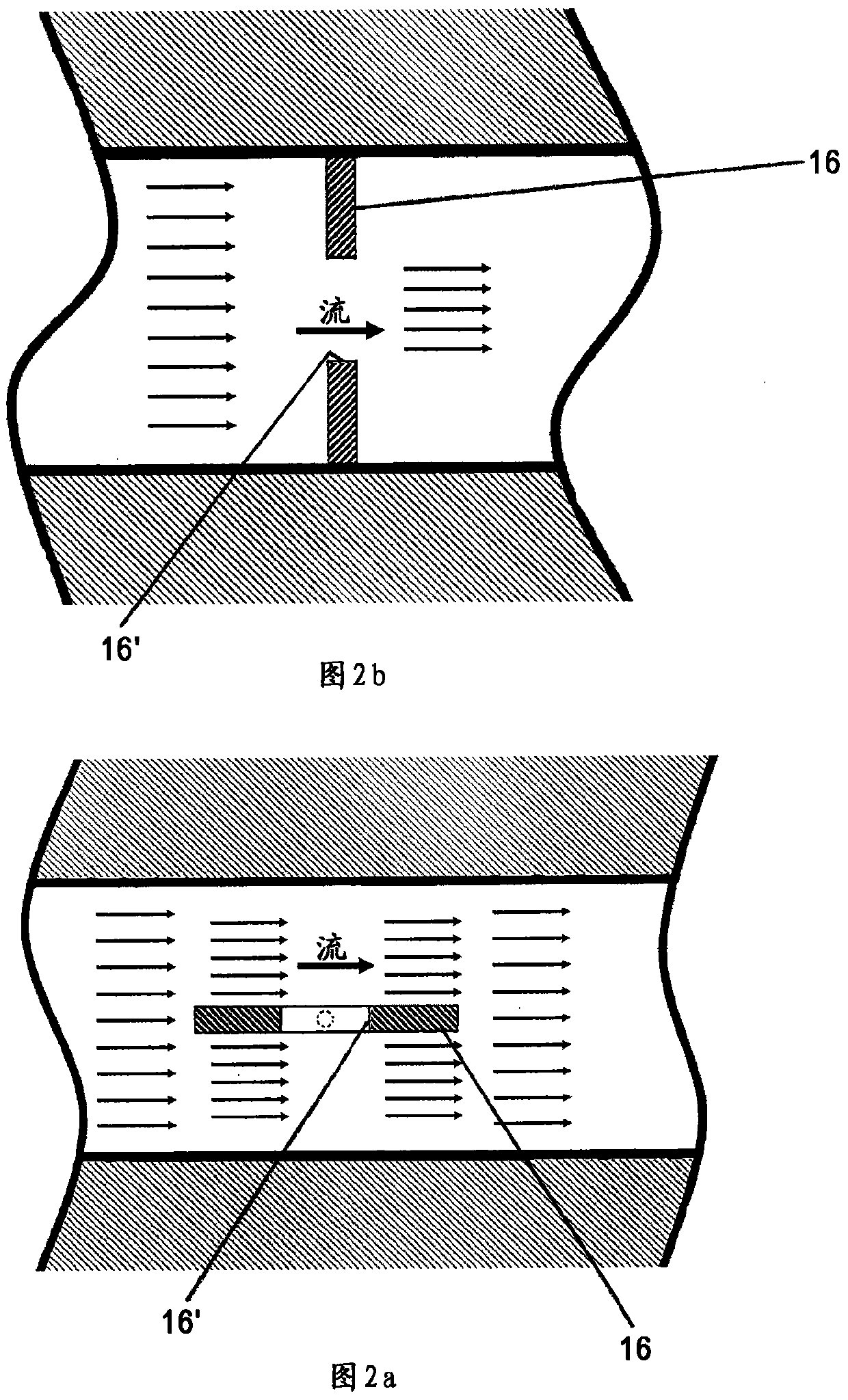

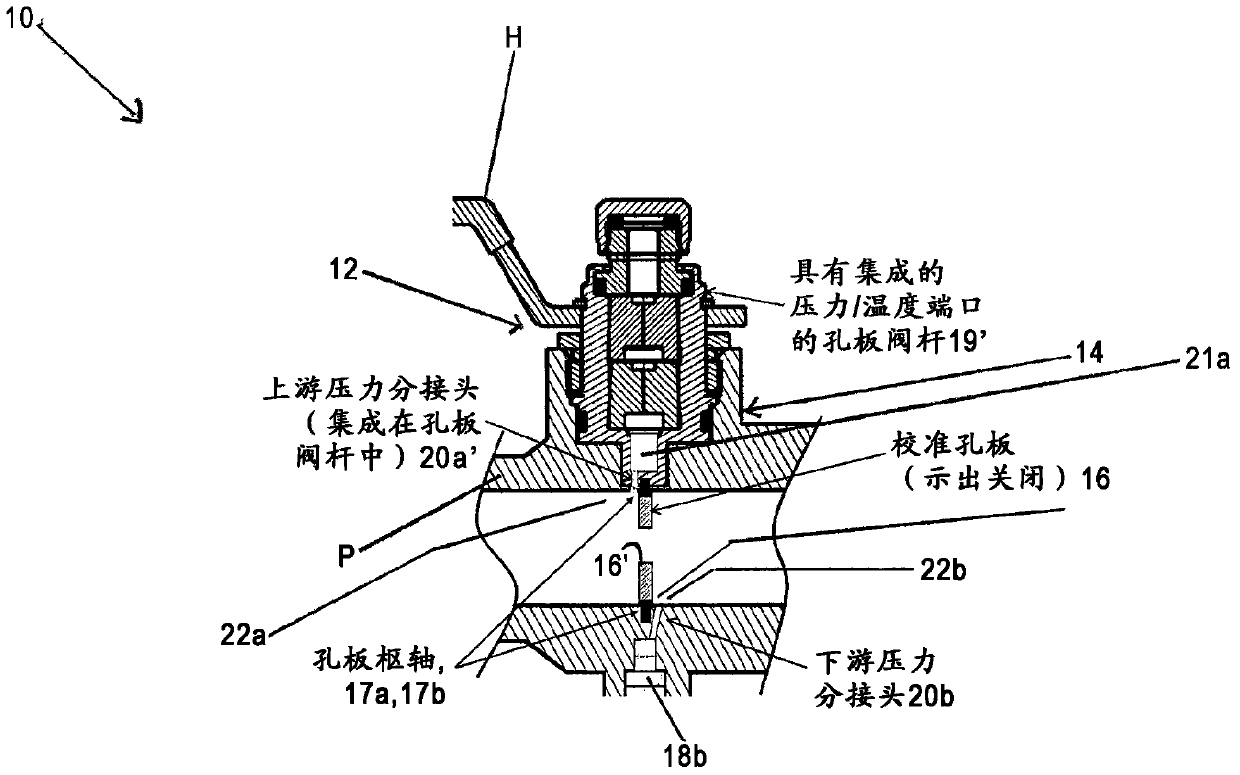

[0049] Figure 1 to Figure 7

[0050] under normal circumstances, figure 1 with Figure 3-7 Both show a cross-sectional view of a device indicated as a whole at 10, the device having a valve indicated as a whole at 12, the valve has a valve body or housing indicated as a whole at 14, which is configured to be arranged in a pipe with a fluid flow F P may form part of the pipeline.

[0051] in figure 1 with Figure 3-7 In this case, the valve body or housing 14 is configured to have at least one pressure tap 20a, 20b arranged at at least one position 22a, 22b along the pipe P to allow the pressure of the fluid flow F of the pipe P to be measured .

[0052] For example, in figure 1 In this case, the valve 12 includes an orifice plate 16 having an opening 16' and configured to be in the valve body or valve housing 14, for example about the orifice plate pivots 17a, 17b as shown, rotating about the axis of rotation A, the axis A Positioned at a position 22c different from the at leas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap