Fat tire tread pattern structure

A tread pattern and tire technology, applied in the direction of tire tread/tread pattern, vehicle parts, tire parts, etc., can solve the problems of aggravating riding, heavy weight, poor mud and snow removal performance, etc., to ensure Grip and off-road performance, increased axial rigidity, increased edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

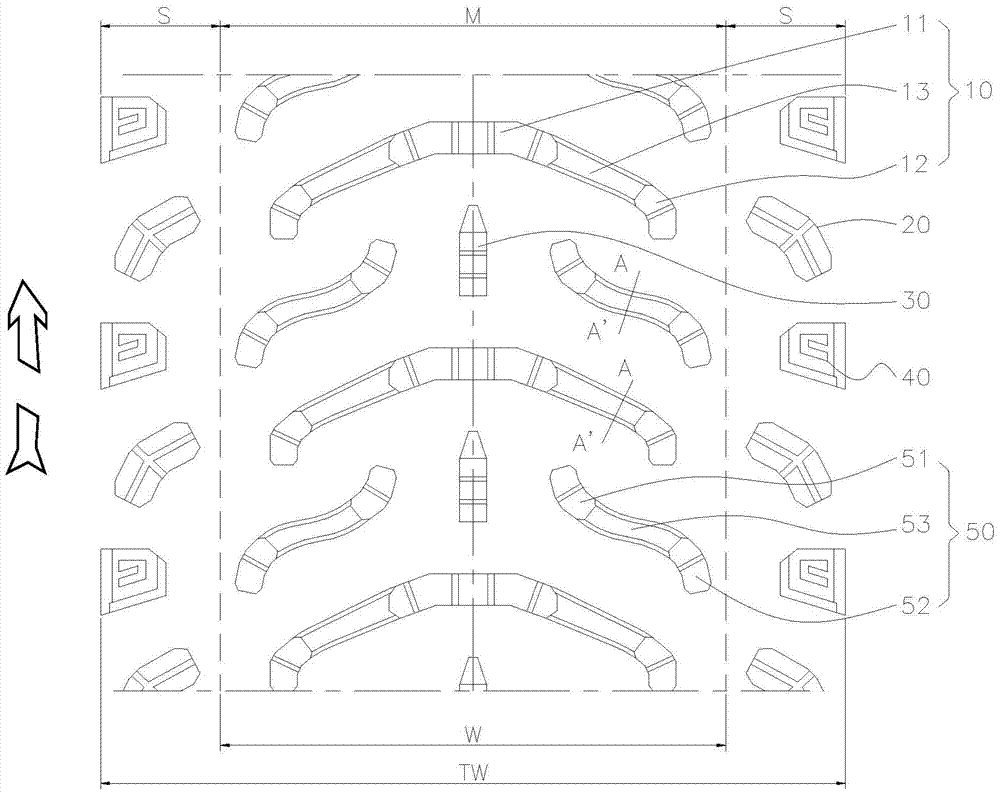

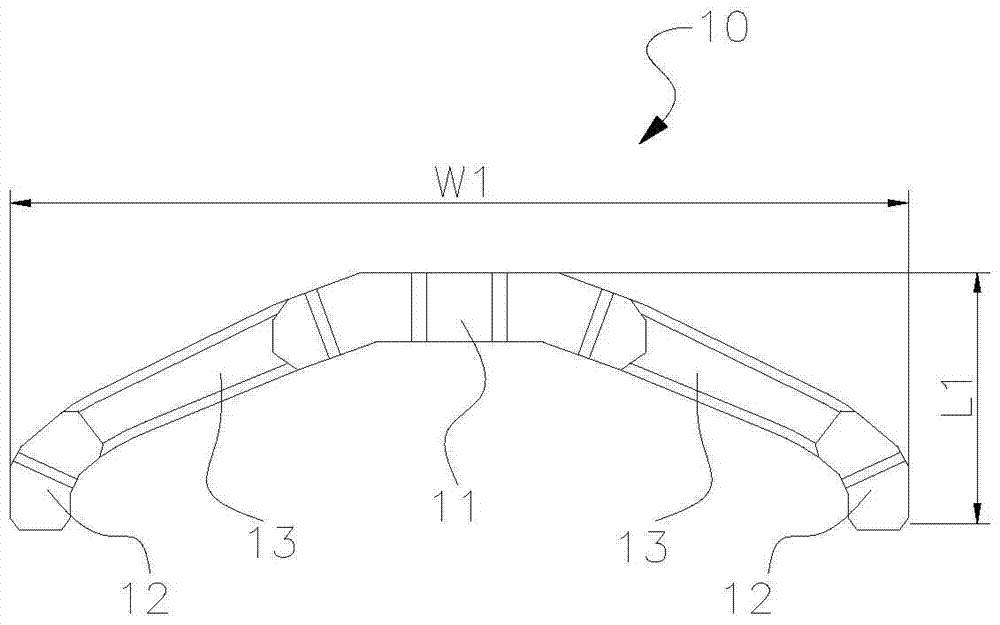

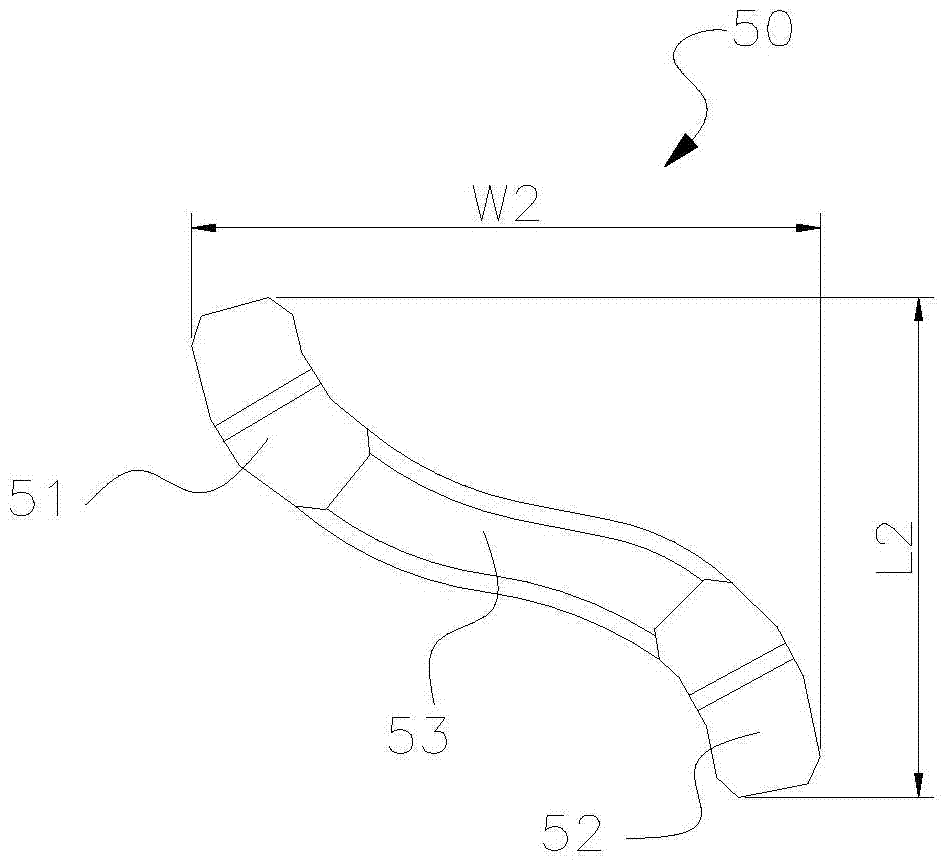

[0024] Such as Figure 1 to Figure 5 As shown, the present invention discloses a tread pattern structure of a fat tire. The vertical direction in the figure is set as the tire radial direction, the transverse direction is set as the tire axial direction, and the single dotted line indicates the equatorial plane.

[0025] Such as figure 1 As shown, the tread of the tire of the present invention has several raised pattern blocks distributed at intervals, and the pattern blocks are arranged symmetrically along the equator plane. Since fat tires have a wider tread and use less wind pressure, the tread can be divided into the main contact area M and two shoulder areas S according to the actual grounding conditions, where the width W of the main contact area M is set It is 55% to 80% of the total tread width TW. In the main contact area M, there are horizontal ribs 10 arranged in the center of the tread that are generally in the shape of an inverted C, and vertical ribs 30 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com